Hand-push-type positioned seeding device for peanut planting

A peanut planting and seeding device technology, applied in the directions of sowing, fertilizing devices, planter parts, etc., can solve the problems of misaligned ground ridges, peanut seed damage, stuck peanut seeds, etc., and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

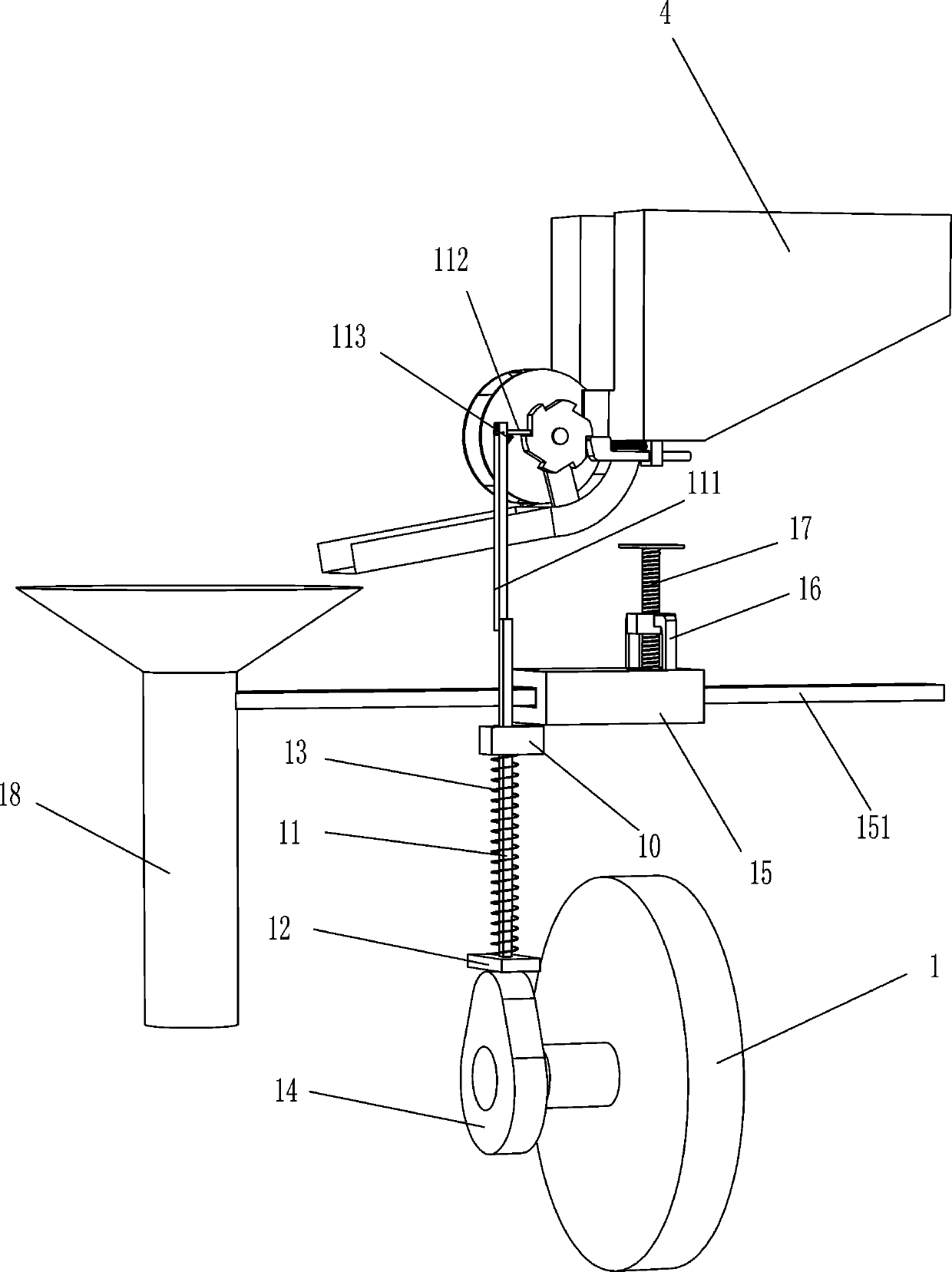

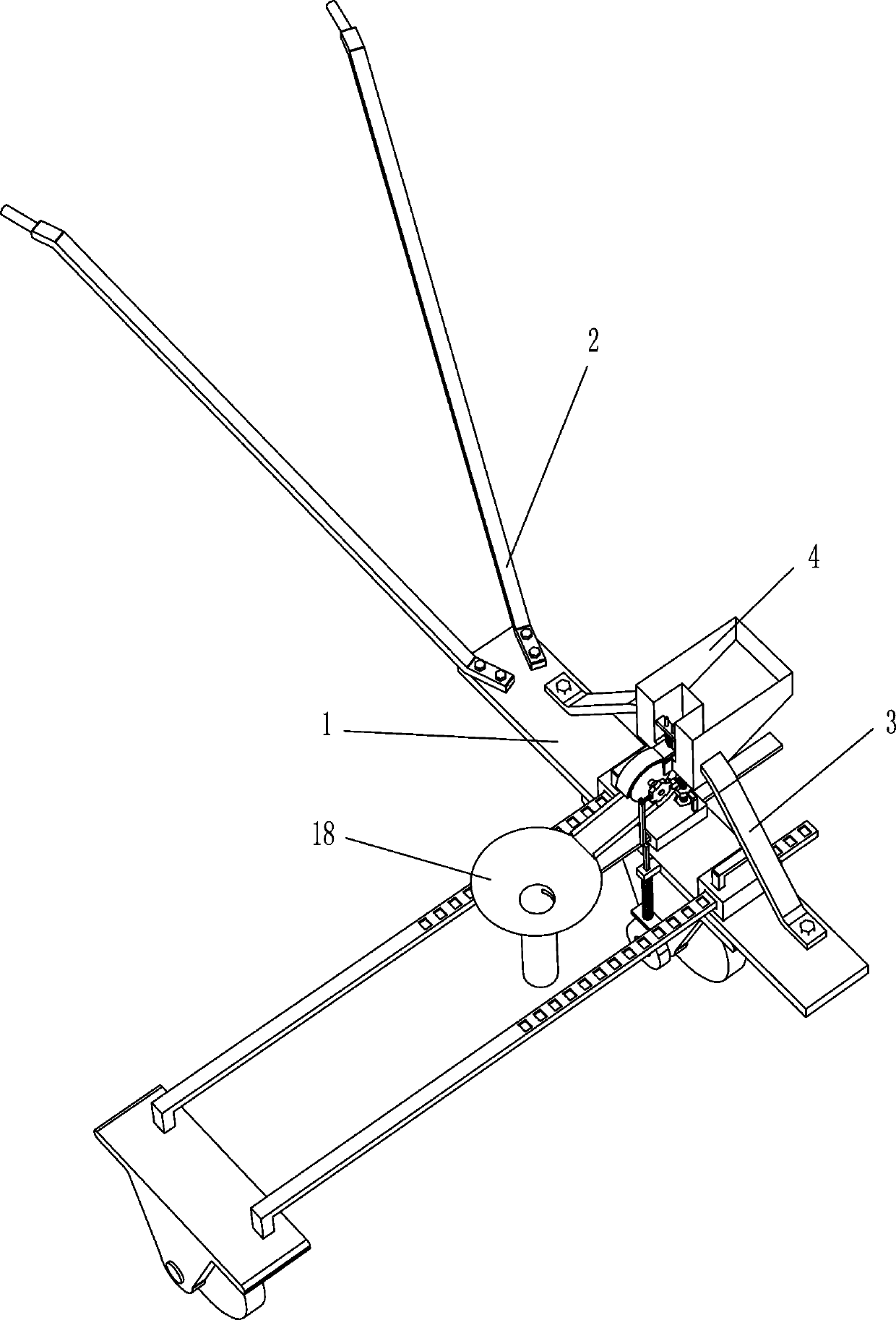

[0059] A hand-push peanut planting positioning sowing device, as shown in the figure, such as Figure 1-3 As shown, it includes vehicle frame 1, handrail 2, supporting plate 3, charging box 4, drain plate 5, rotating shaft 6, feeding tray 7, chuck 8, clamping device 9, movable sliding sleeve 10, sliding rod 11, pole 111, swing bar 112, top spring 113, top plate 12, return spring 13, cam 14, guide sleeve 15, guide rod 151, nut 16, screw rod 17 and funnel 18, vehicle frame 1 is equipped with wheels, Two handrails 2 are fixedly connected to the upper left side of the vehicle frame 1, and the two handrails 2 are symmetrical. The lower ends of the two support plates 3 are fixedly connected to the left and right sides above the vehicle frame 1. The upper end of the support plate 3 is fixedly connected and is located in the middle of the two support plates 3. The charging box 4 is provided with a leakage hole. The leakage plate 5 is connected to the bottom of the charging box 4. The ...

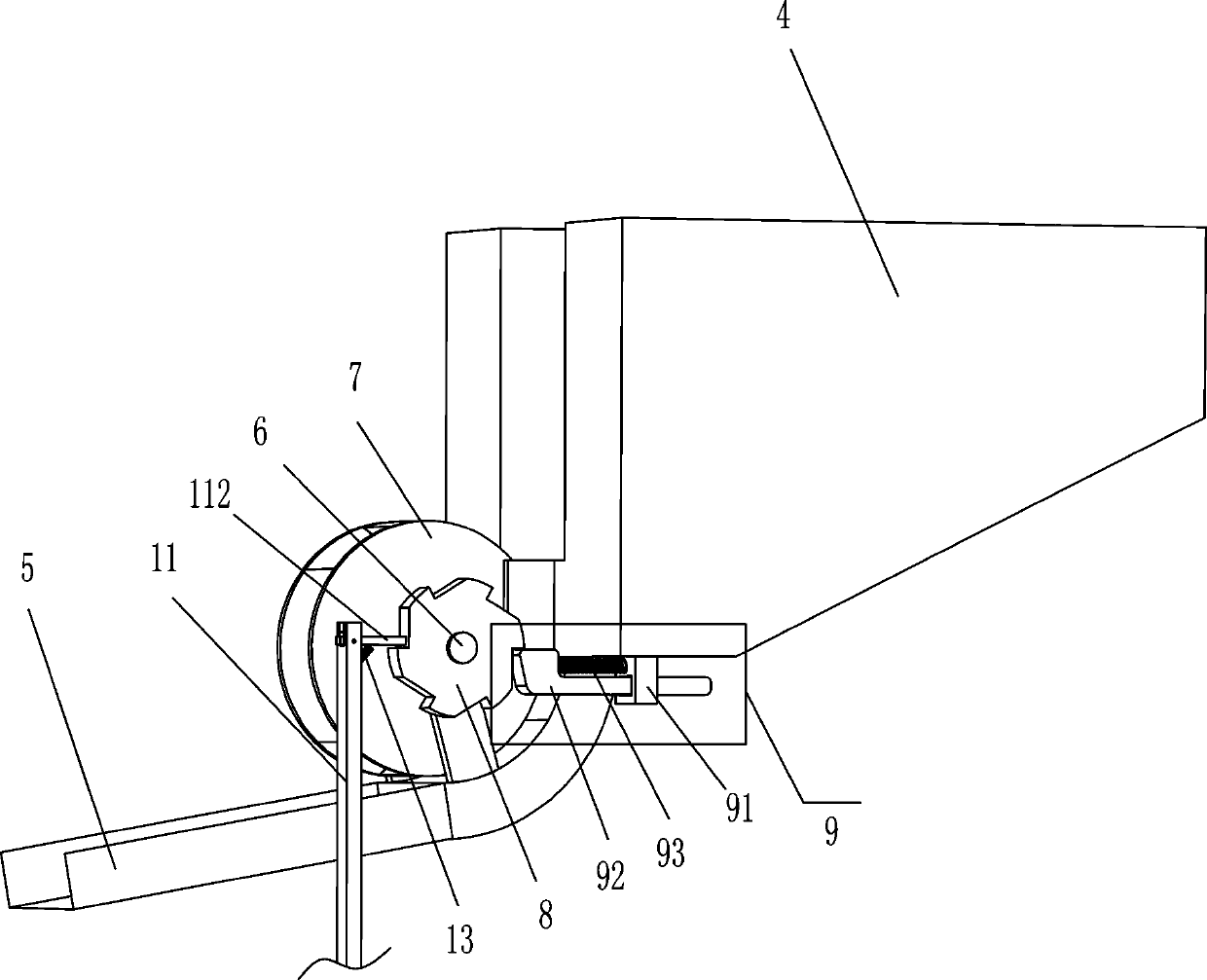

Embodiment 2

[0062] On the basis of Example 1, such as image 3 As shown, the clamping device 9 includes a clamping sliding sleeve 91, a clamping lever 92 and a return spring 93, the clamping sliding sleeve 91 is fixedly connected to the lower right side of the charging box 4, and the clamping lever 92 is slidably connected to the Inside the tight sliding sleeve 91 , the clamping rod 92 is in contact with the chuck 8 , one end of the return spring 93 is fixedly connected to the clamping sliding sleeve 91 , and the other end is fixedly connected to the clamping rod 92 .

[0063] When the chuck 8 rotated one tooth forward, the clamping rod 92 clamped the chuck 8 under the promotion of the back-moving spring 93 to prevent the reverse rotation of the chuck 8, and the clamping rod 92 cooperated with the swing rod 112.

[0064] Such as Figure 4 As shown, it also includes an adjustment sleeve 19, an adjustment rod 20, a draw-in groove 21, a fixed clamp rod 22 and a balance wheel 23. There are ...

Embodiment 3

[0067] On the basis of Example 2, such as Figure 5 As shown, it also includes a fixed plate 24, a cylindrical rod 25, a hold-down plate 26 and a hold-down spring 27. The fixed plate 24 is affixed to the middle part of the front side outer wall of the charging box 4, and the fixed plate 24 has two through holes. Two cylindrical rods 25 pass through the through holes on the fixing plate 24 respectively, the two cylindrical rods 25 are symmetrical, and the pressing plate 26 is fixedly connected to the lower ends of the two cylindrical rods 25, and the pressing plate 26 is located at the bottom of the charging box 4 leakage hole and Above the material tray 7, one end of the compression spring 27 is affixed to the bottom of the fixed plate 24, and the other end is affixed to the top of the compression plate 26. The compression spring 27 is located in the middle of the two cylindrical rods 25.

[0068] When too many peanut seeds are piled up from the leakage hole, the pressing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com