Novel clamp

A fixture, a new type of technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high brick loading cost, inconvenient brick loading, low efficiency, etc., achieve low production cost, improve brick loading efficiency, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

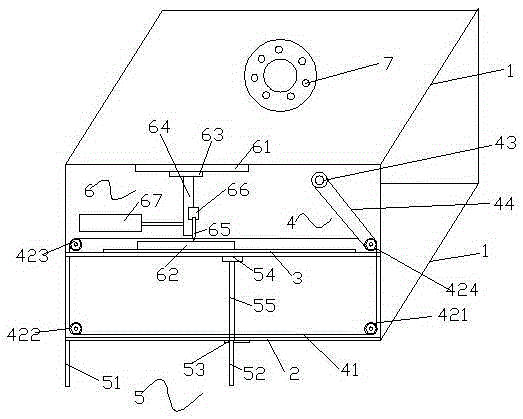

Image

Examples

Embodiment 1

[0020] Embodiment 1, the chain 41 is a chain with spikes, the positioning rod 65 is a hollow rod, and the inner diameter of the hollow rod is larger than the minimum diameter of the spikes of the chain. When the movable clip and the fixed clip are clamped, the upper and lower cylinders move the hollow rod down, so that the hollow rod is placed on the sharp part of the chain, and then the hollow rod is pushed by the force of the horizontal cylinder, and the hollow rod transmits the horizontal force to the chain, so that the movable clip clamps the bricks so that the bricks will not fall down. The function of slider three and slider four is to increase the clamping force of the clip, so that the clip has enough clamping force to clamp the brick block so that it does not slip.

Embodiment 2

[0021] Embodiment 2 is different from Embodiment 1 in that the end of the positioning rod 65 is conical, the chain is composed of a single roller chain, there is no spike on the chain, and the end of the positioning rod It can pass through the roller chain and connect with the slider three. When the movable clip is clamped with the fixed clip, the upper and lower cylinders will move the positioning rod down, so that the lower end of the positioning rod passes through the roller chain, so that the lower end of the positioning rod is connected with the slider three, and then pushed by the force of the horizontal cylinder The positioning rod, the positioning rod transmits the horizontal force to the chain, so that the movable clip clamps the brick so that the brick will not fall. The function of the slider three and the slider four is to increase the clamping force of the clip, so that the clip There is enough clamping force to clamp the brick so that it does not slip off.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com