Nickel bath water drainage system structure for PCB (printed circuit board) electroless nickel immersion gold line

A drainage system and nickel tank technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of increasing sewage treatment costs, nickel tank mother liquor and product scrapping, and avoid tank liquid and product waste. Disposal, good maintenance of the environment, and the effect of reducing the generation of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

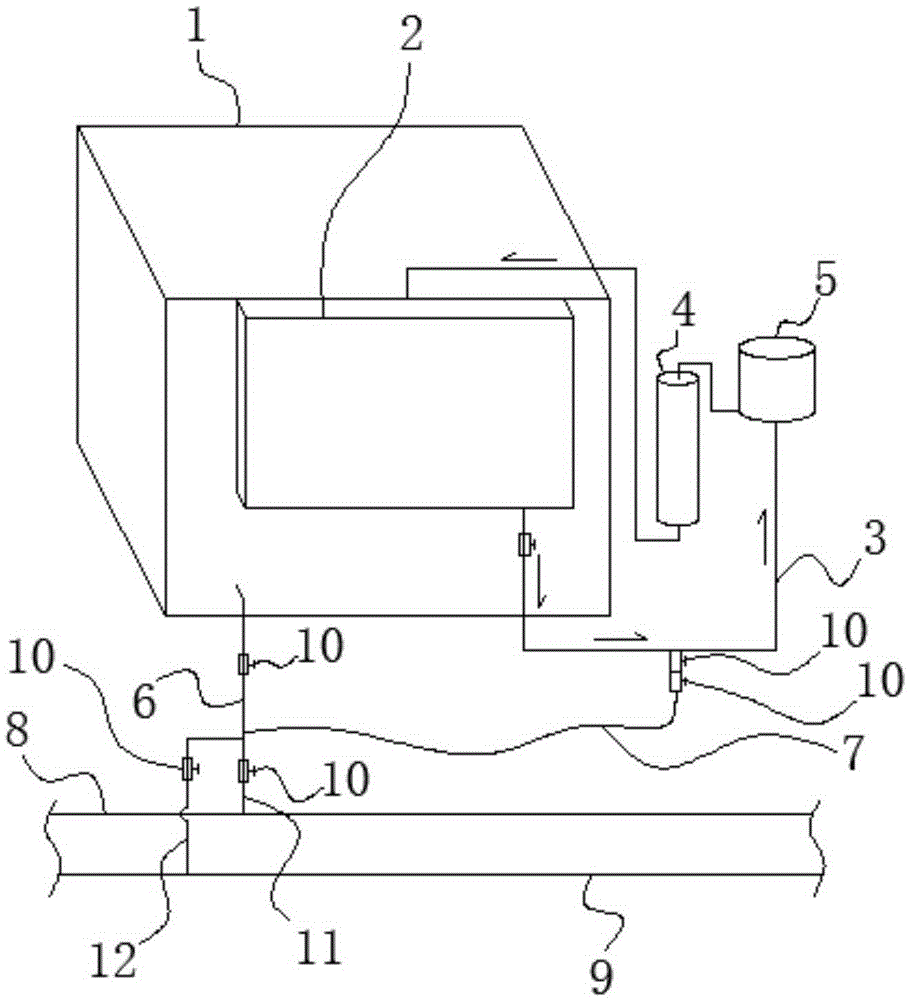

[0015] Embodiment: a kind of drainage system structure of PCB gold wire nickel tank, the nickel tank has a main tank 1 and a secondary tank 2, a circulation pipeline 3 is provided between the main tank and the secondary tank, and a circulation pipeline is provided on the circulation pipeline There is a filter device 4 and a pump 5, the main tank has a main tank drain pipe 6, the secondary tank has a secondary tank drain pipe 7, and the nickel tank has a high-concentration waste water discharge pipe 8 and a washing water discharge pipe 9 , the circulation pipeline 3 starts from the drain port of the auxiliary tank 2 and leads into the main tank 1, the circulation pipeline 3 is provided with a valve 10, and the pump 5 is located in the filter device Before 4, on the circulation pipeline 3 and on the pipe section before the pump 5, a secondary tank drain pipe 7 is connected, and the secondary tank drain pipe 7 is a hose, and the secondary tank drain pipe 7 One end is detachably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com