Self-resetting mild steel energy dissipation support

An energy-dissipating support and self-resetting technology, which is applied to bridge parts, building components, bridges, etc., can solve the problems of large residual deformation, large lateral deformation, and high building maintenance costs, and achieve good plastic deformation ability and reduce side effects. The effect of deformation and good energy dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

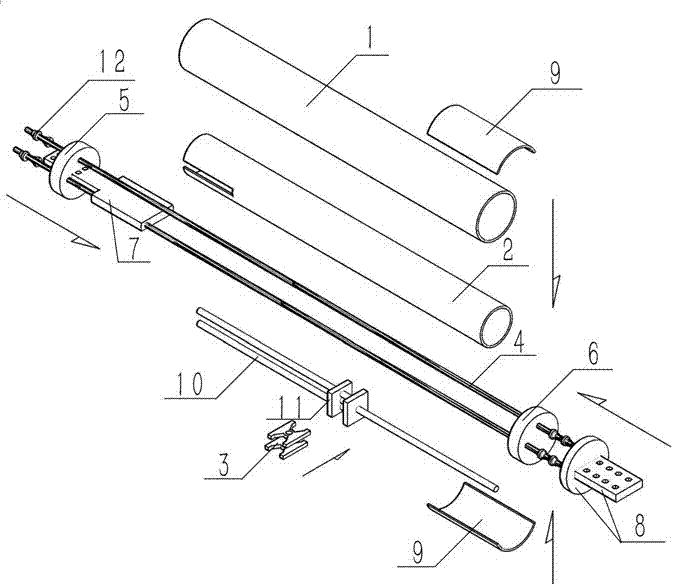

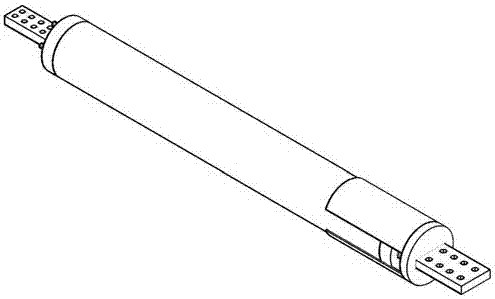

[0034] Embodiment 1: as figure 1 As shown, it is an embodiment of a self-resetting mild steel energy dissipation support of the present invention, which mainly includes an outer sleeve 1, an inner sleeve 2, mild steel 3, reset ribs 4, a first end plate 5, and a second end plate 6 , Convex connecting plate 7, combined connecting plate 8, arc welding jigsaw 9, dowel bar 10, backing plate 11, clip-type anchor 12 and guide block 13.

[0035] The outer casing 1 and the inner casing 2 adopt a hollow circular cross-section. Of course, in order to ensure a certain degree of rigidity and a safety reserve for stability, the wall thickness should not be too thin.

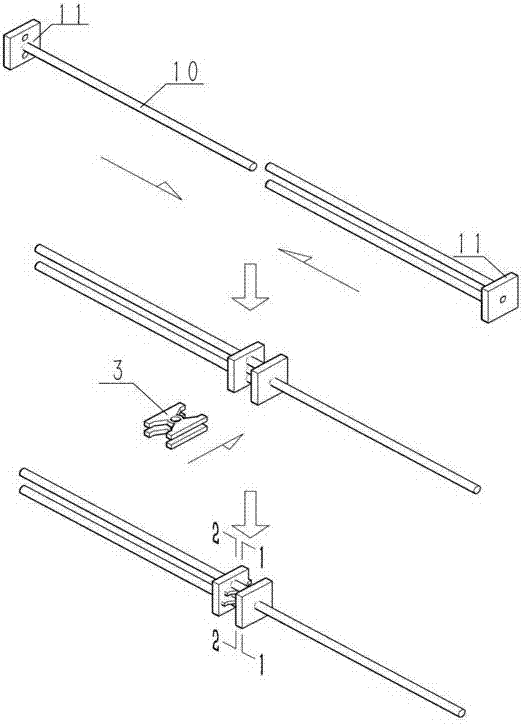

[0036] The force transmission device consists of three dowel bars 10 and two backing plates 11, one backing plate 11 is welded to the two dowel bars 10 at both ends, and a through hole with a diameter slightly larger than the dowel bar 10 is opened in the center ; Another backing plate 11 is welded and connected with a dowel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com