TBM (Tunnel Boring Machine) high-efficient rock-crushing cutter head with ultrasonic vibrator

An ultrasonic and vibrator technology, applied in the field of TBM high-efficiency rock crushing cutter head, can solve the problems of affecting the tunnel excavation speed and construction cost, poor wear resistance of domestic hob, low rock crushing speed of hob, etc., to improve rock drilling. Speed, reduce construction cost, good effect of crushing rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

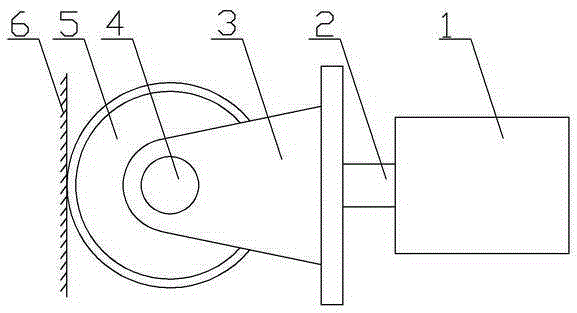

[0016] see figure 1 As shown, the present embodiment is composed of an ultrasonic vibrator 1, a vibrating rod 2, a support structure 3, a cutter shaft 4 and a disc-shaped hob 5 of a rock excavator, and the ultrasonic vibrator 1 is fixed by the vibrating rod 2 and the supporting structure 3 On the cutter shaft 4 of the disc-shaped hob 5 of the rock excavator, the ultrasonic wave generated by the ultrasonic vibrator 1 transmits the high-frequency vibration to the cutter shaft 4 through the vibrating rod 2 and the support structure 3, and the cutter shaft 4 drives the disc-shaped hob of the rock excavator. The hob 5 impacts the rock 6 at high frequency while cutting the rock 6, so as to accelerate the expansion of cracks in the rock 6 and effectively break the rock.

[0017] The working principle of this embodiment:

[0018] The high-frequency vibration generated by the ultrasonic vibrator 1 is directly transmitted to the disc hob 5 of the rock boring machine through the cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com