Double w-shaped combustion chamber applicable to opposed injection

A combustion chamber and fuel oil technology, which is applied to combustion engines, fuel injection devices, internal combustion piston engines, etc., can solve problems such as the reduction of oil-gas mixing quality and fuel spray collision, so as to improve combustion performance, increase utilization rate, and avoid fuel spray The effect of the collision problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

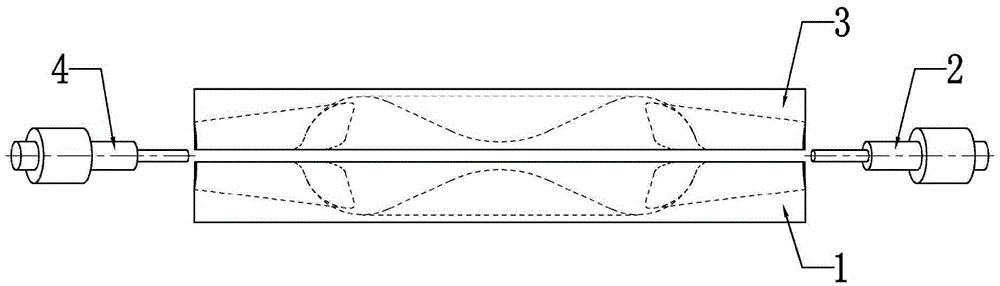

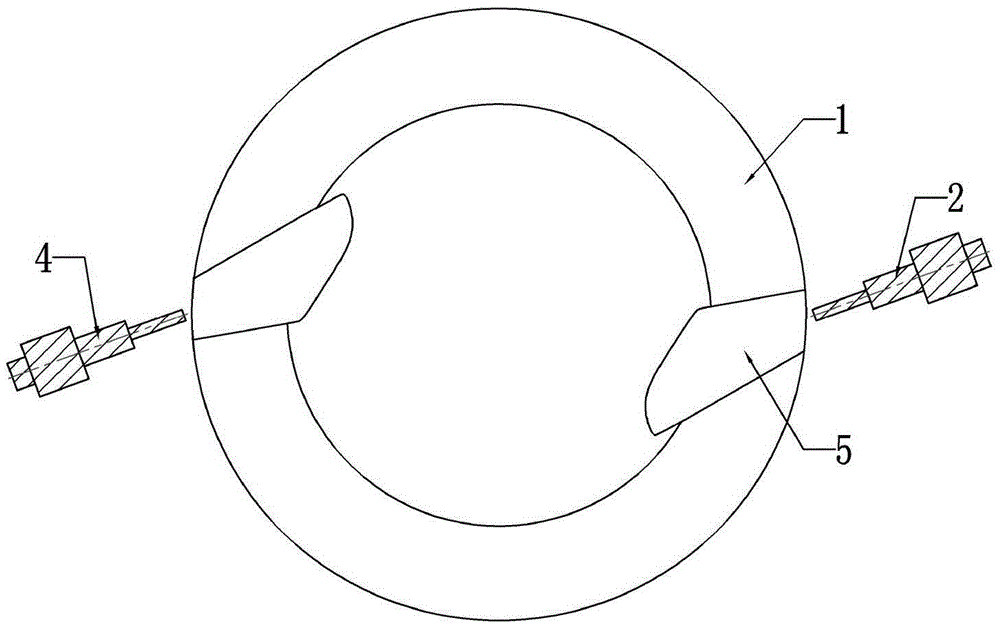

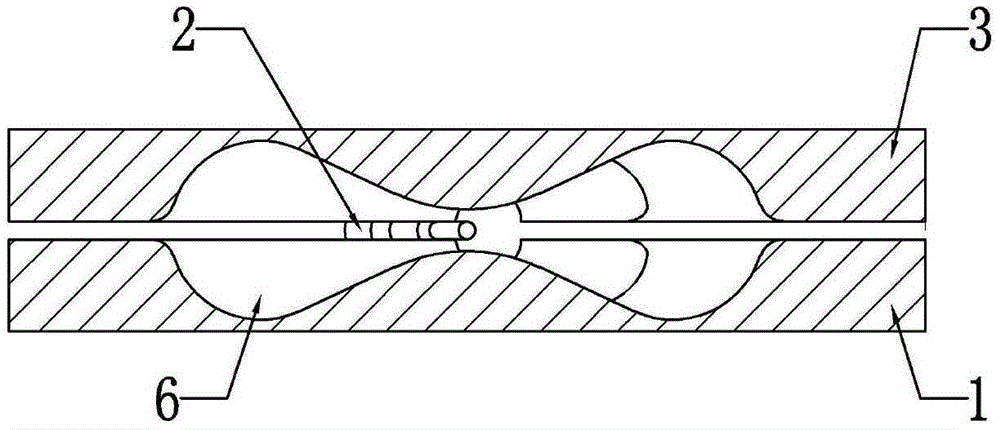

[0021] A double ω-type combustion chamber suitable for opposed injection described in the present invention, such as Figures 1 to 3 As shown, it includes an intake side combustion chamber 1 and an exhaust side combustion chamber 3 which are parallel and oppositely arranged. An ω-shaped pit 6 is provided; the combustion chamber 1 on the intake side and the combustion chamber 3 on the exhaust side are provided with fuel spray at the adjacent cutouts of injector one 2 and injector two 4 on both sides Guide structure 5, the fuel spray guide structure 5 is a gradually expanding beam structure designed according to the direction of the fuel oil beam; Figure 4 , 5 As shown, the fuel spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com