A fuel supply system for marine dual-fuel engines that can avoid loss of natural gas exchange

A dual-fuel engine and fuel supply system technology, applied in combustion engines, internal combustion piston engines, charging systems, etc., can solve problems such as environmental damage and resource waste, and achieve the effects of economical combustion, waste avoidance, and environmental damage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

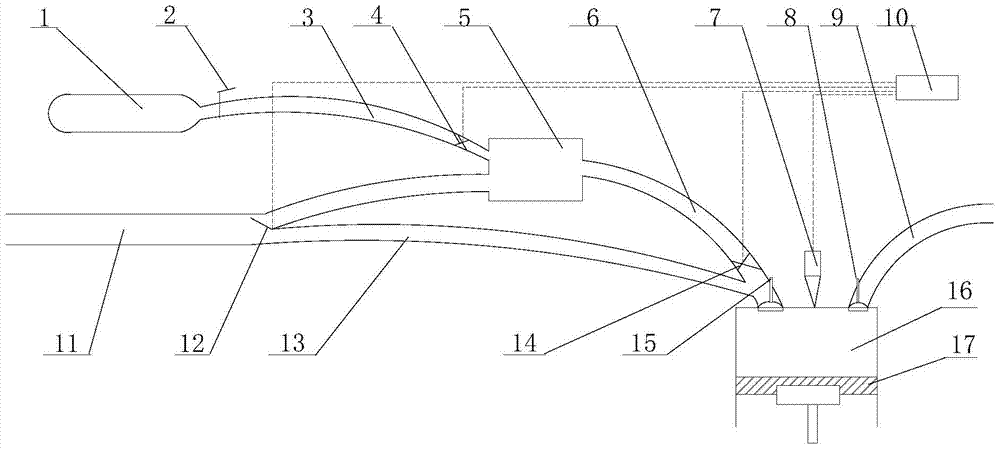

[0015] combine figure 1 The natural gas tank 1 is connected to the natural gas channel 3, and the natural gas channel 3 is connected to the natural gas and air mixer 5; a safety valve 2 is installed at the inlet of the natural gas channel 3, and a natural gas intake control valve 4 is installed at the outlet; the air main pipe 11 is controlled by a throttle valve 12 Divided into two upper and lower pipes, one is called air channel 13, leading to the upper part of the intake valve 15, where the upper part of the intake valve 15 is about 8 cm and converges with the mixed gas inlet channel 6; the other is connected upward to the mixer 5; the mixed gas The outlet is connected to the mixed gas inlet port 6, and the mixed gas inlet port 6 converges with the air inlet port 13 at about 8 cm above the intake valve 15 to form a manifold connected to the intake valve 15, lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com