Tire type coupling

A coupling and tire-type technology, applied in the field of machinery, can solve the problems of increasing the additional axial force, low bearing capacity, and increased bearing load, etc., and achieve the effects of prolonged service life, low production cost, and reasonable settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

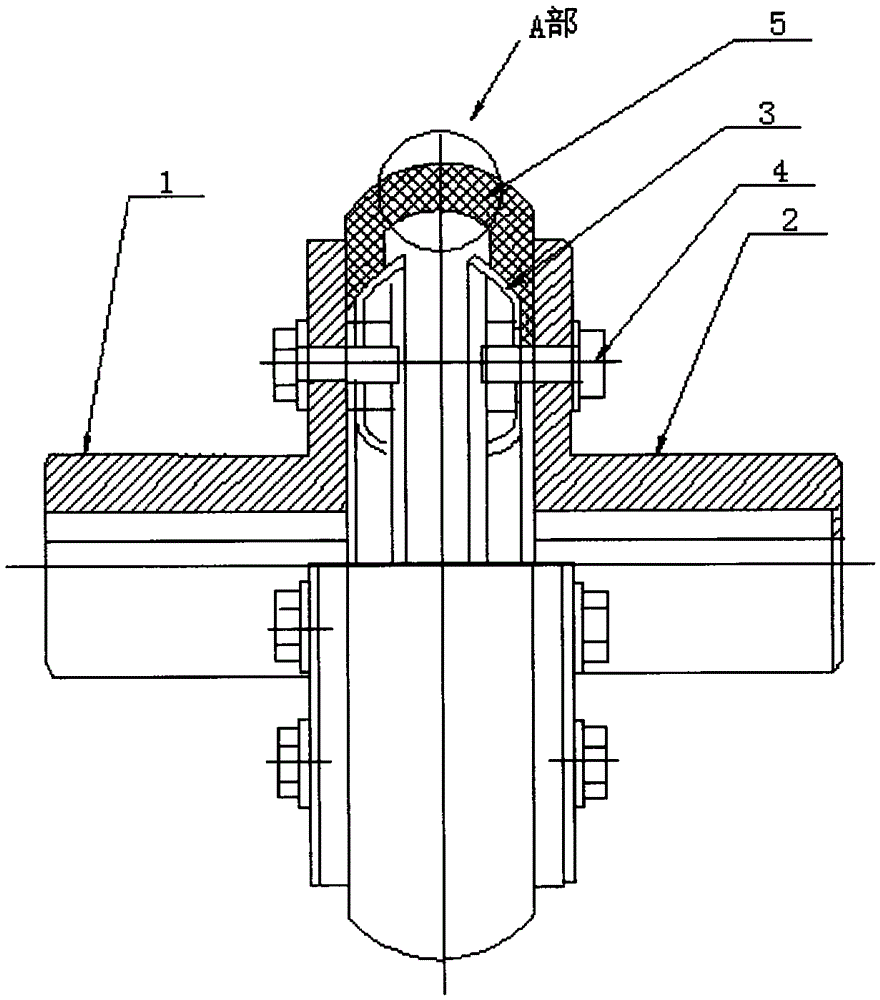

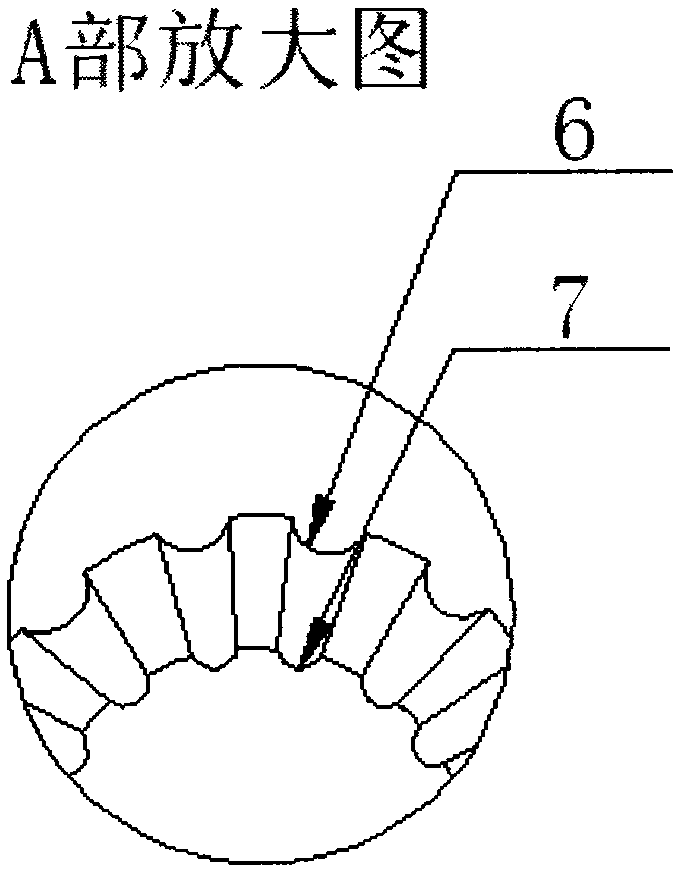

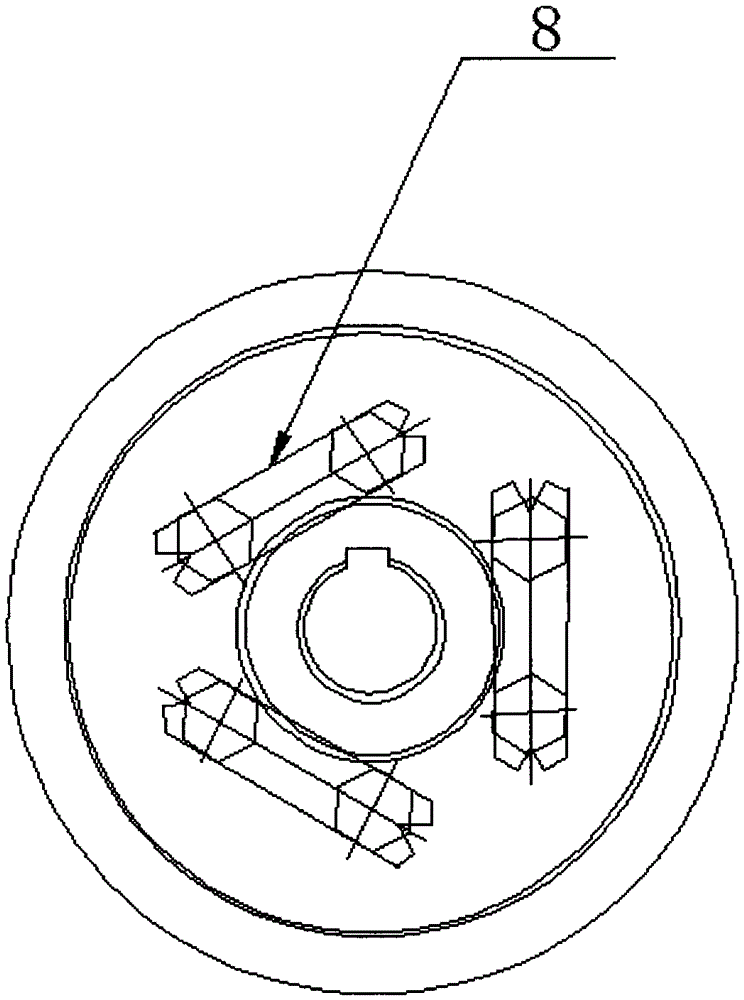

[0017] see as figure 1 —— image 3 As shown, this specific embodiment adopts the following technical scheme: it includes a left half coupling 1, a right half coupling 2, a metal pressure plate 3, a bolt 4, a tire body 5, a first arc groove 6, a second arc shaped groove 7; the two sides of the tire body 5 are provided with metal pressure plates 3; the left half coupling 1 and the right half coupling 2 are respectively arranged on the left and right sides of the tire body 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com