Aerodynamic model tester for aero-engine

A technology of aero-engine and aerodynamic model, which is applied in aerodynamic test, engine test, machine/structural component test, etc. It can solve problems such as difficulty in giving calculation results, inability to realize multi-stream flow pressure, precise temperature control, etc. , to achieve the effect of compact structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

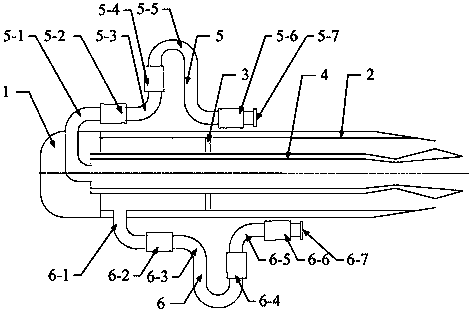

[0010] Including: engine precursor simulation structure 1; outer shell 2; inner support device 3; inner shell 4; inner air intake device 5; outer air intake device 6; inner inner inlet connecting pipe 5-1; inner end expansion joint 5-2; connotation 90° connecting pipe 5-3; connotation middle expansion joint 5-4; connotation 270° connecting pipe 5-5; connotation front expansion joint 5-6; connotation intake pipe joint 5-7; external culmination inlet connection Pipe 6-1; expansion joint at the end of the outer culvert 6-2; 90° connecting pipe of the outer culvert 6-3; middle expansion joint 6-4 of the outer culvert; 270° connecting pipe of the outer culvert 6-5; front end expansion joint of the outer culvert 6- 6; Outer culvert intake pipe joints 6-7.

[0011] The engine precursor simulation structure 1 is fixedly connected with the outer casing 2 to form the shape of the aerodynamic model tester of the aero-engine test equipment; the inner casing 4 is coaxially placed in the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com