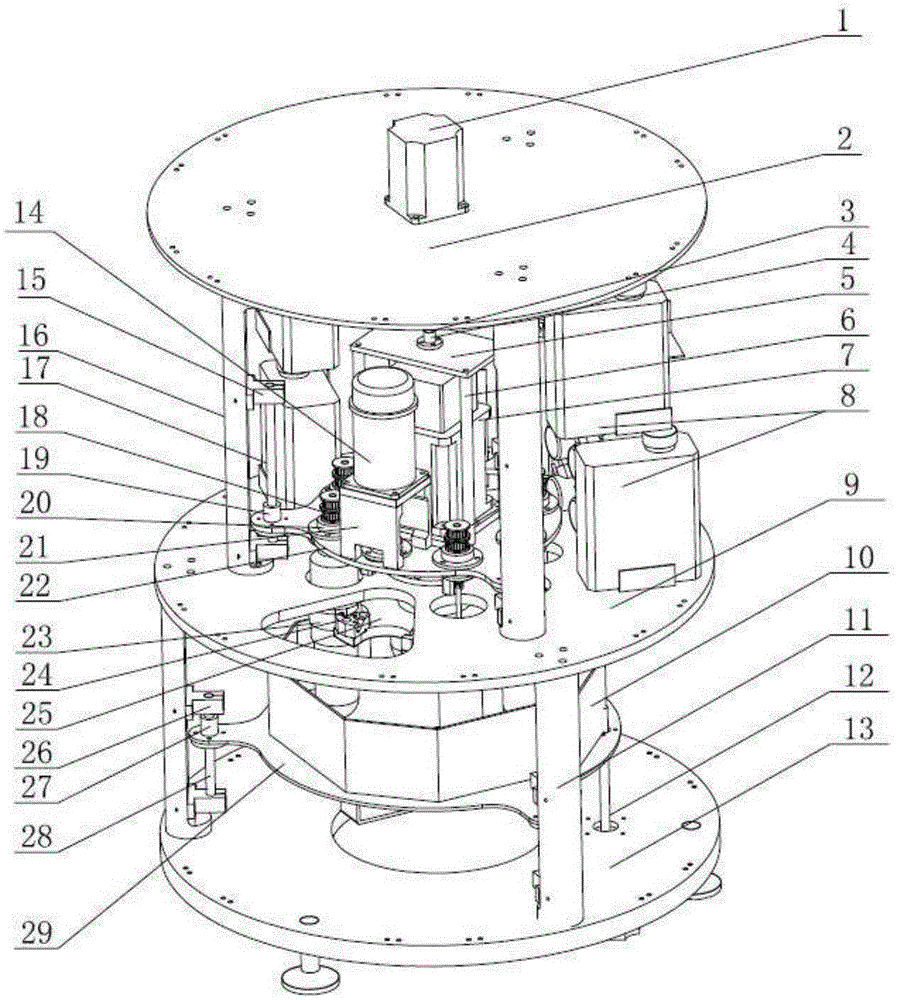

Food sample preprocessing instrument for food safety testing and processing method thereof

A sample pretreatment and food safety technology, which is applied to the food sample pretreatment instrument and its processing field for food safety testing, can solve the problems of increasing human resources investment cost, time-consuming and laborious, and low penetration rate, and achieve shortening of detection and processing time, Effect of improving centrifugal efficiency and improving installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

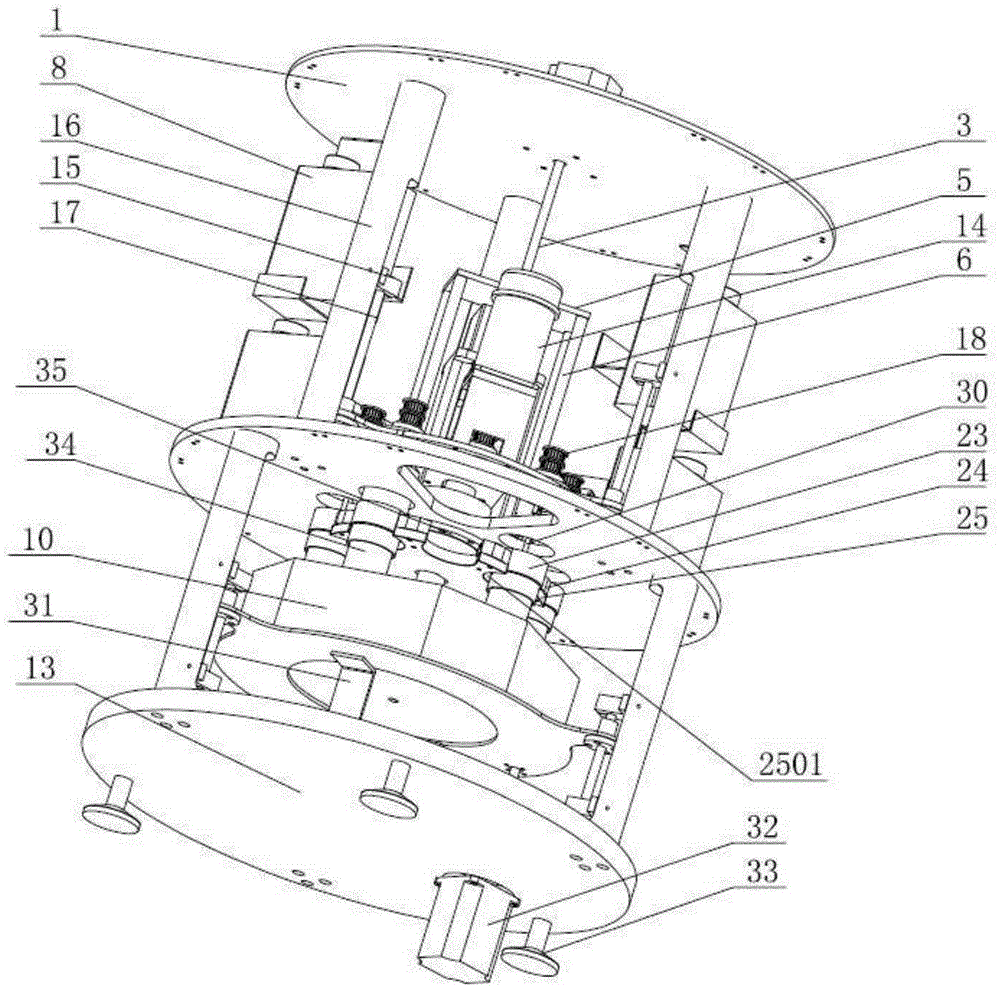

[0059] The processing method for detecting the content of methylene methanol in soybean louvers by using the above-mentioned food sample pretreatment instrument includes the following steps:

[0060] Step 1: Add 1 g of soybean louver and 10 g of water into each centrifuge tube 34 .

[0061] The second step: the first lifting motor 1 is controlled by PLC to start, the first lifting motor 1 drives the first screw rod 3 to go down, and the first screw rod 3 drives the upper moving plate 22 through the servo motor cover horizontal plate 5 and support column 6 A guide column 17 moves up and down, makes the servomotor 7, stirring motor 14 and the stirring rod 30 in the multi-stage transmission mechanism installed on the moving plate move downward, until the stirring rod 30 stretches into the centrifuge tube 34 and mixes with water and The jellyfish wire contacts, and then the first lifting motor 1 is controlled by PLC to close.

[0062] The third step: the PLC controls the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com