Device and method achieving triaxial shear tests of samples of different sizes

A three-axis shearing and dimensioning technology, which is applied in the direction of applying stable shearing force to test the strength of materials, etc., can solve the problems of seal ring damage, uneven bolt installation tightness, high operating costs of enterprises, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

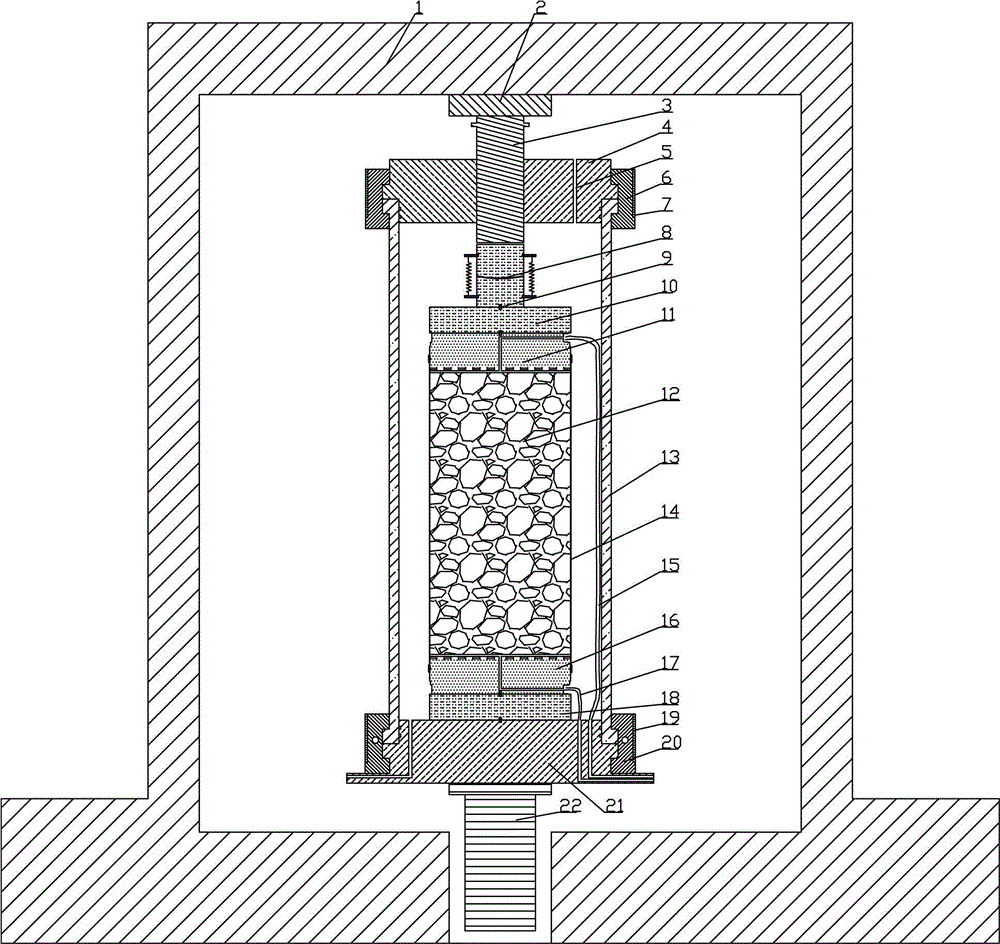

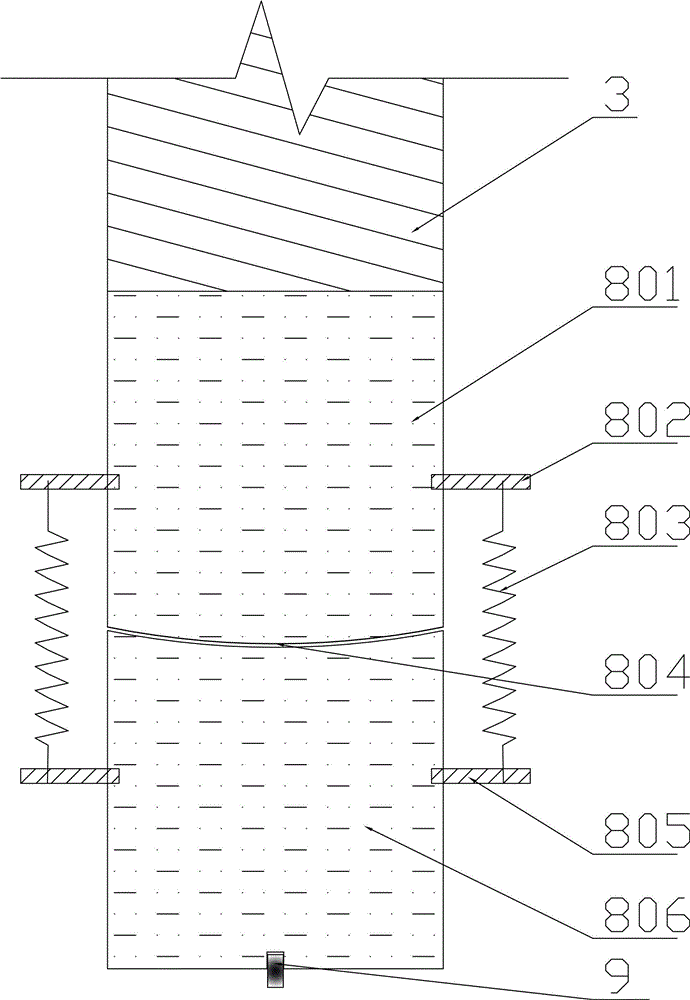

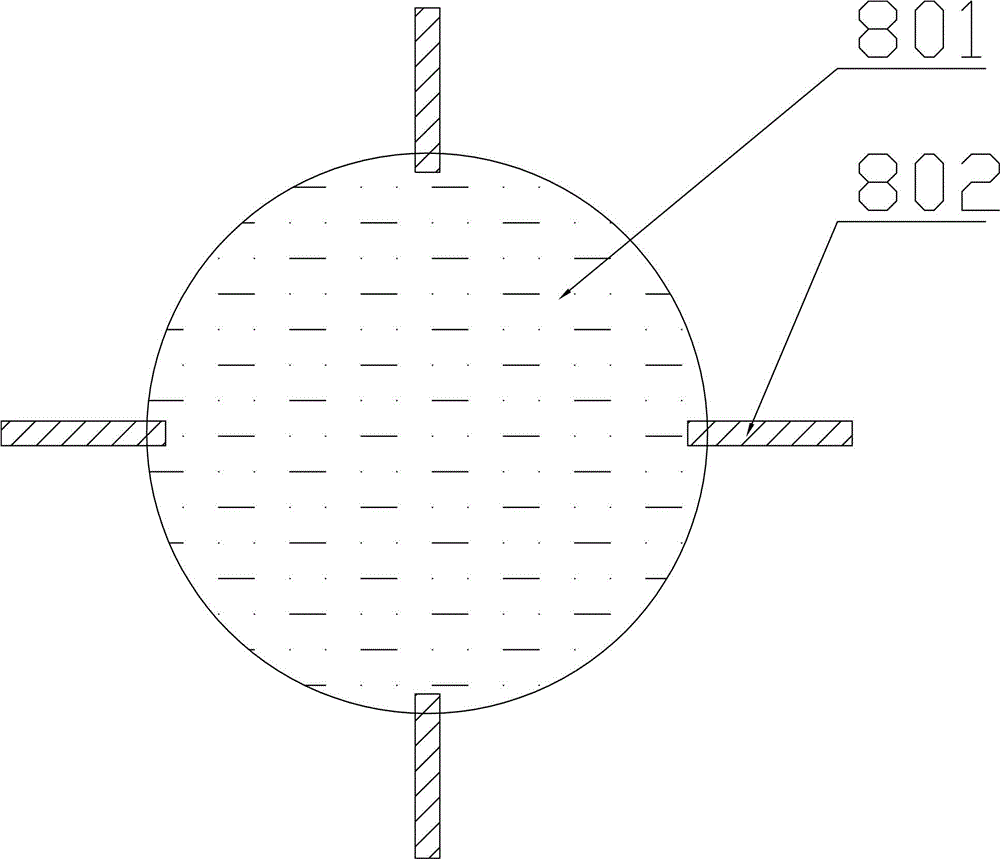

[0053] Such as figure 1 As shown, a device that satisfies the triaxial shear test of samples of different sizes, it includes a reaction force frame 1, the bottom of the reaction force frame 1 is provided with a power source 22, and the sample 12 in the test process is raised by the power source 22. Power, the top of the power source 22 is provided with a movable base 21, the upper part of the movable base 21 is provided with a lower pad 18, the lower pad 18 is provided with a lower permeable pad 16, and the top of the lower permeable plate 16 is installed with a sample 12 , the outer surface of the sample 12 is provided with a latex film 14, the top of the sample 12 is provided with an upper permeable plate 11, and the top of the upper permeable plate 11 is provided with an upper pad 10, and the top of the upper pad 10 is positioned by the upper positioning pin 9 A self-balancing ball head device 8 is installed, and the axial dowel rod 3 passes through the upper cover 4 of the...

Embodiment 2

[0066] Adopt the test method of above-mentioned triaxial shear test device, it comprises the following steps:

[0067] 1. Select the matching upper block 10, upper permeable plate 11, lower permeable plate 16 and lower block 18 according to the sample size required by the test.

[0068] 2. The bottom end of the latex film 14 is fixed on the outer wall of the lower permeable plate 16 through the lower sealing ring 1603, and then the film-forming barrel for loading samples is installed on the outside of the latex film 14, and samples are prepared according to the requirements of the geotechnical test regulations. After the sample is completed, the upper water-permeable plate 11 is placed on the top of the sample 12, and the upper end of the latex film 14 is fixed on the outside of the upper water-permeable plate 11 through the upper sealing ring 1104, thereby completing the test preparation.

[0069] 3. After the sample preparation is completed, select the upper block 10 of appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com