A device for measuring expansion rate of oil well cement test block

An oil well cement and measuring device technology, applied in the direction of material thermal expansion coefficient, etc., can solve problems such as unreasonable structural design, high material cost, gas channeling, etc., and achieve the effect of improving measurement accuracy and accuracy and reducing test data errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

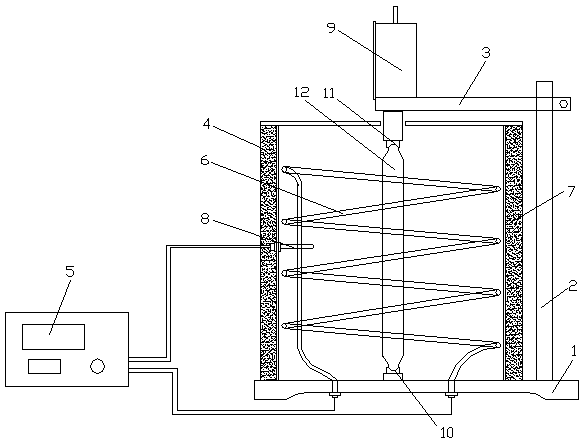

[0041] see figure 1 , a kind of oil well cement test piece expansion ratio measuring device, comprises base 1, column 2 and clamping arm 3, the lower end of column 2 is connected with base 1, the upper end of column 2 is connected with clamping arm 3, also includes thermostatic box 4 and A thermostat 5, the thermostat 4 is fixed on the base 1, the inner wall of the thermostat 4 is connected with a heating pipe 6, the outer wall of the thermostat 4 is connected with an insulation layer 7, and the inner wall of the thermostat 4 is connected with a thermocouple 8. The temperature controller 5 is electrically connected to the thermocouple 8 and the heating tube 6 respectively, the dial indicator 9 is connected to the clamping arm 3, and the lower recess 10 is fixed on the inner bottom wall of the thermostat 4 , the upper recess 11 is fixed on the top wall, the upper recess 11 runs through the top wall of the incubator 4 and is connected with the dial gauge 9, and a standard rod 12...

Embodiment 2

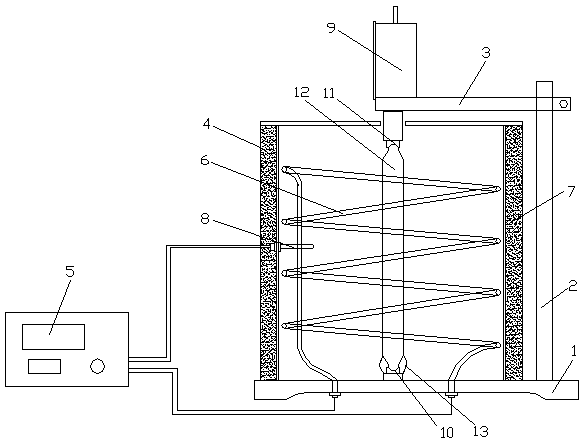

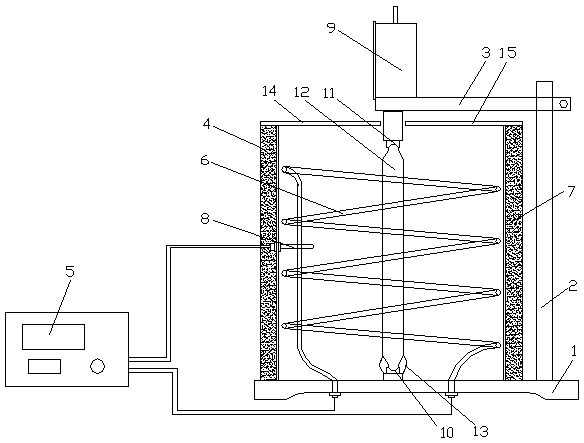

[0044] see figure 2 , a kind of oil well cement test piece expansion ratio measuring device, comprises base 1, column 2 and clamping arm 3, the lower end of column 2 is connected with base 1, the upper end of column 2 is connected with clamping arm 3, also includes thermostatic box 4 and A thermostat 5, the thermostat 4 is fixed on the base 1, the inner wall of the thermostat 4 is connected with a heating pipe 6, the outer wall of the thermostat 4 is connected with an insulation layer 7, and the inner wall of the thermostat 4 is connected with a thermocouple 8. The temperature controller 5 is electrically connected to the thermocouple 8 and the heating tube 6 respectively, the dial indicator 9 is connected to the clamping arm 3, and the lower recess 10 is fixed on the inner bottom wall of the thermostat 4 , the upper recess 11 is fixed on the top wall, the upper recess 11 runs through the top wall of the incubator 4 and is connected with the dial gauge 9, and a standard rod 1...

Embodiment 3

[0048] see figure 2 , a kind of oil well cement test piece expansion ratio measuring device, comprises base 1, column 2 and clamping arm 3, the lower end of column 2 is connected with base 1, the upper end of column 2 is connected with clamping arm 3, also includes thermostatic box 4 and A thermostat 5, the thermostat 4 is fixed on the base 1, the inner wall of the thermostat 4 is connected with a heating pipe 6, the outer wall of the thermostat 4 is connected with an insulation layer 7, and the inner wall of the thermostat 4 is connected with a thermocouple 8. The temperature controller 5 is electrically connected to the thermocouple 8 and the heating tube 6 respectively, the dial indicator 9 is connected to the clamping arm 3, and the lower recess 10 is fixed on the inner bottom wall of the thermostat 4 , the upper recess 11 is fixed on the top wall, the upper recess 11 runs through the top wall of the incubator 4 and is connected with the dial gauge 9, and a standard rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com