Cable fault detection testing system and working method thereof

A test system, a technology for cable faults, applied in the fault location, detecting faults by conductor type, etc., can solve the problems of difficulty in obtaining the fault location, distortion of reflected signals, high acquisition rate, easy balance calibration, and small information value. , Improve the effect of collecting bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

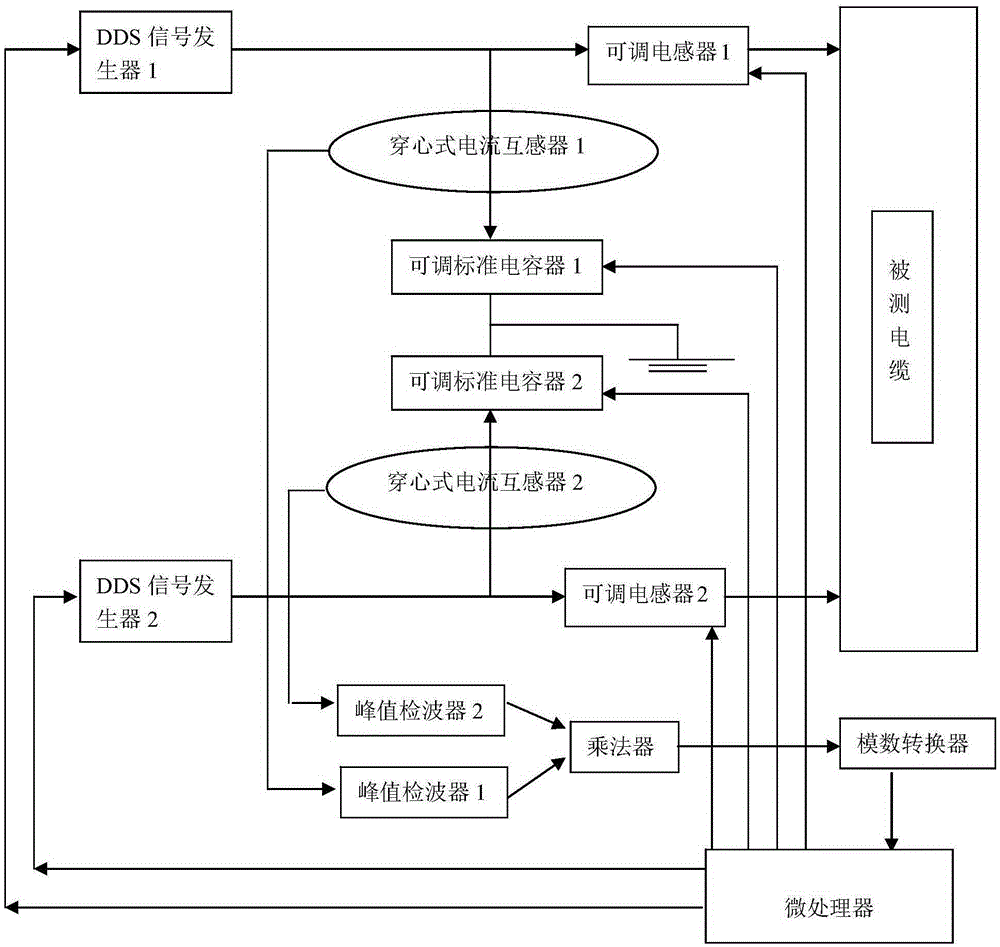

[0024] Such as figure 1 shown. Carry out fault detection for 10kV XLPE cables with a length of 600m, and build a cable fault detection test system, specifically including: a microprocessor using an ARM chip, responsible for the control of the entire monitoring test system, and controlling the sent control data and received The data is calculated and analyzed; the DDS signal generator 1 controlled by the microprocessor generates a rectangular wave signal 1 with adjustable frequency and amplitude; the DDS signal generator 2 controlled by the microprocessor generates adjustable frequency and amplitude The rectangular wave signal 2, the frequency and amplitude of the rectangular wave signal 2 are consistent with the rectangular wave signal 1; the adjustable inductor 1, whose inductance is controlled by the microprocessor, is connected in series between the DDS signal generator 1 and the cable under test, Send the received rectangular wave signal 1 into the cable under test, filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com