Reaction kettle used for diode failure analysis experiment

A technology for failure analysis and experiments, applied in the direction of measuring devices, instruments, electrical components, etc., can solve the problems of high labor intensity of experimenters, waste of experimental samples, and high cost of experiments, so as to reduce instability and danger and avoid duplication Experiments, the effect of improving the efficiency of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

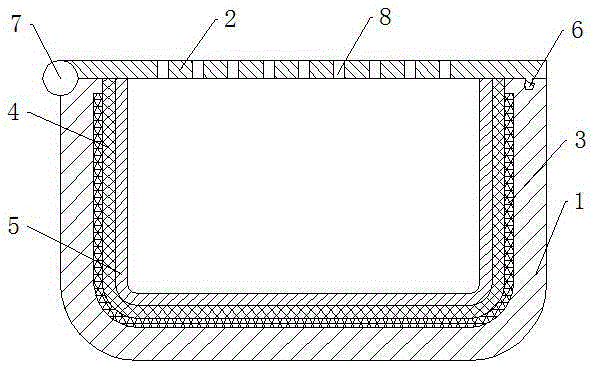

[0013] The reference signs in the drawings of the description include: body 1 , end cap 2 , heating wire 3 , heat conduction layer 4 , cuvette 5 , card table 6 , hinge 7 , and drain hole 8 .

[0014] The embodiment is basically as attached figure 1 Shown: a reaction kettle for diode failure analysis experiments, including a body 1 and an end cover 2, the body 1 is a circular cup-shaped upper end made of ceramics, and the inner wall and bottom of the body 1 are provided with annular Groove, copper heating wire 3 is fixed in the groove. The outer side of the heating wire 3 is provided with a heat conduction layer 4, and the heat conduction layer 4 is a thin ceramic plate. A cuvette 5 is arranged on the outside of the heat conducting layer 4, and the cuvette 5 is made of potassium glass. The end cover 2 is hinged on one side of the upper end of the body 1 through a hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com