Electric linear actuator with sealed lubrication and overload protection structure

A linear drive, overload protection technology, applied in the direction of structural connections, electric components, electrical components, etc., can solve the problems of wear and damage, easy corrosion of screw mechanisms, lack of overload protection of electric cylinders, etc., to avoid overload damage, prolong life, reduce weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

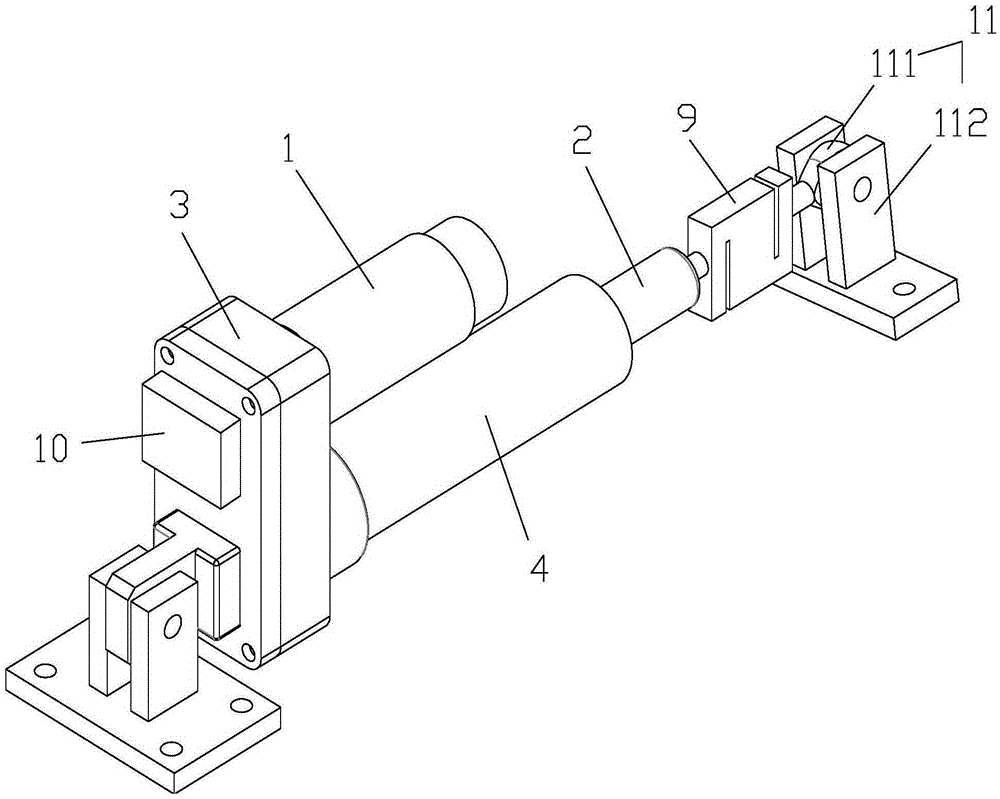

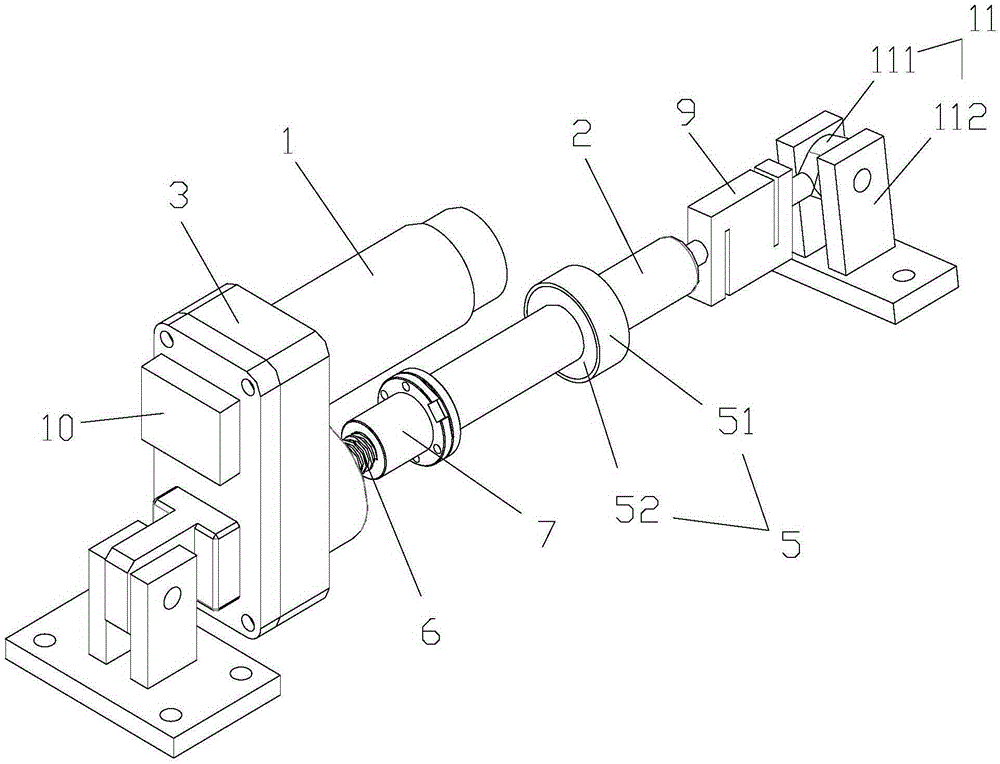

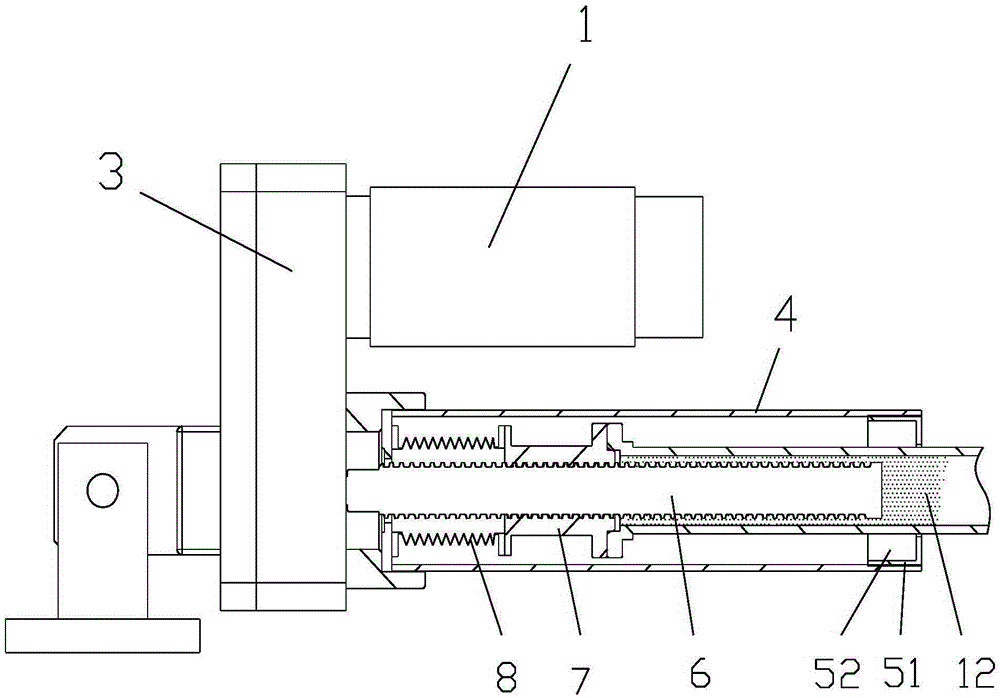

[0022] As shown in the figure, the electric linear driver with sealed lubrication and overload protection structure in this embodiment includes a motor 1, a sliding sleeve 2, a screw mechanism that pushes the sliding sleeve to reciprocate linearly, a reducer 3 that connects the motor and the screw mechanism, And the support device for supporting the sliding sleeve, the support device includes a support tube 4 sleeved outside the screw mechanism, one end of the support tube is fixed on the housing of the reducer, and the other end of the support tube is provided with a guide support 5. The guide support includes a bearing seat 51 fixed in the tube hole at the front end of the support tube and a sliding bearing 52 fixed in the bearing seat, and the sliding bearing is linearly slidingly matched with the sliding sleeve;

[0023] The screw mechanism includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com