Continuous phase change heat sink thermal control unit

A technology of thermal control and phase change heat, which is applied in cooling/ventilation/heating transformation, modification using liquid cooling, etc. It can solve the problems of difficult technical implementation, high cost of modified phase change materials, poor technical economy, etc., and achieve high efficiency. Effect of heat transfer and energy storage, simple technical solution, and quick start performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

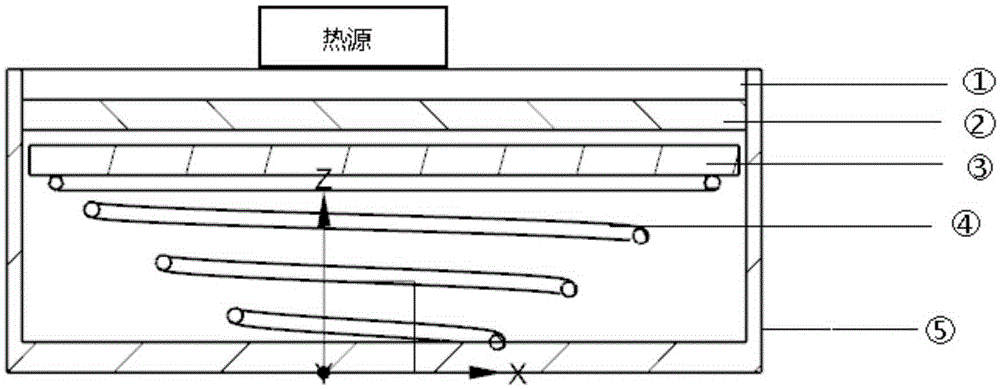

[0012] refer to figure 1 . In the embodiments described below, the thermal control unit of the continuous phase change heat sink includes the phase change material 2 packaged in the closed cavity of the packaging case 5 . A conical spring 4 supporting the pre-tightening pressure plate 3 is provided at the bottom end of the closed cavity of the packaging shell 5, and the phase change material 2 is arranged between the thermal diffusion plate 1 and the pre-tightening pressure plate 3, and the spring pre-tensioning force of the conical spring 4 is Press the phase change material 2 close to the thermal diffusion plate 1. During the phase change process, when the heat source generates heat, the temperature of the heat source and the thermal diffusion plate 1 rises, and the heat source is transferred to the phase change material 2 through the thermal diffusion plate 1 to undergo a phase change. , the phase change material 2 near the inner wall surface of the thermal diffusion plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com