Steam blowing device used for vibrating table

A vibrating table and steam technology, applied in the direction of fluid using vibration, etc., can solve the problems of alarming in the main operating room, affecting the data acquisition accuracy of the vibrating table, affecting the service life of electrical equipment, etc., and achieve the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

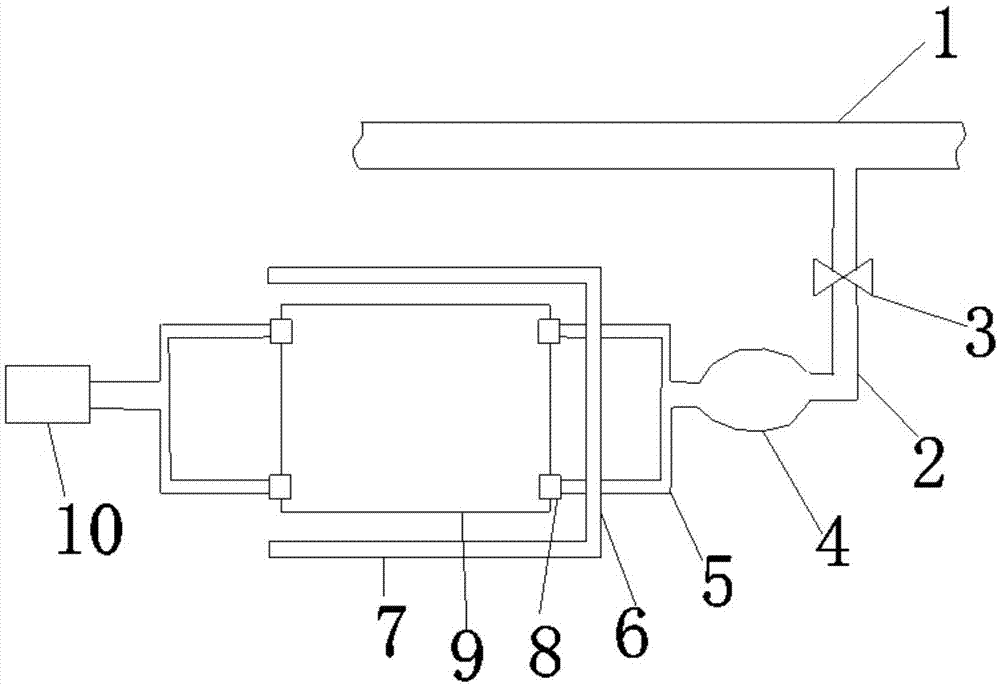

[0022] The invention provides a device for purging steam of a vibrating table, comprising:

[0023] The first branch pipe 2 connected to the workshop protective gas main pipeline 1 is provided with a valve 3, and the diameter of a section of the first branch pipe is larger than the diameter of the remaining part of the first branch pipe, so that An expansion joint 4 is formed, and the expansion joint 4 is located downstream of the valve 3. The expansion joint 4 can buffer the unstable air flow in the protective gas main pipeline 1 of the workshop, so that the gas supply of the first branch pipe 2 is continuous, and the blowing The sweeping effect is stable;

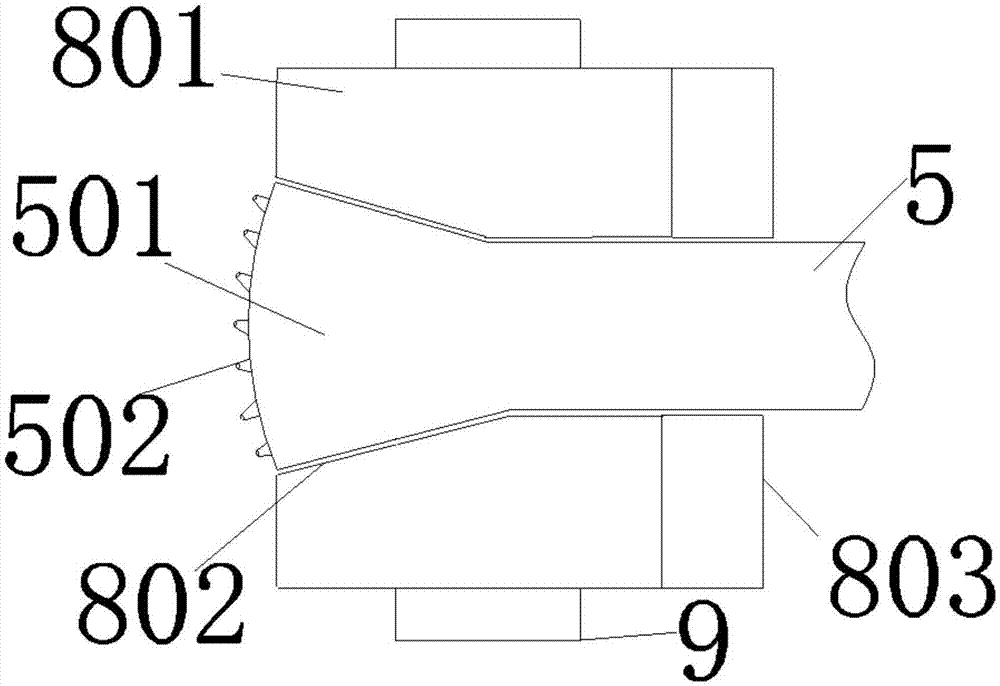

[0024] At least two second branch pipes 5, the at least two second branch pipes 5 are all communicated with the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com