Ultra-thin heat sink for LED lamps, heat dissipation aluminum plate and manufacturing method thereof

A technology for LED lamps and radiators, which is applied to heat exchange equipment, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of bulky radiators and the inability to effectively solve the problem of heat dissipation of high-power LED lighting equipment, etc. Achieve the effect of high heat transfer speed, diversified high-power lighting requirements, and excellent heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

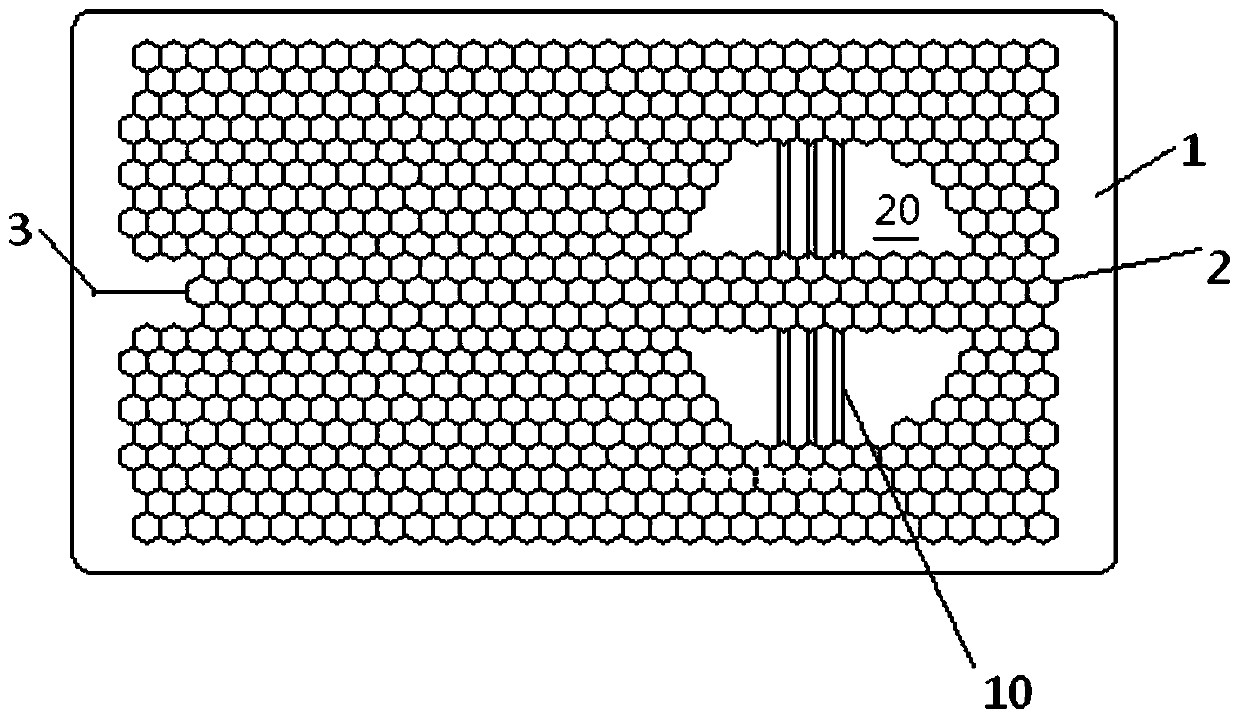

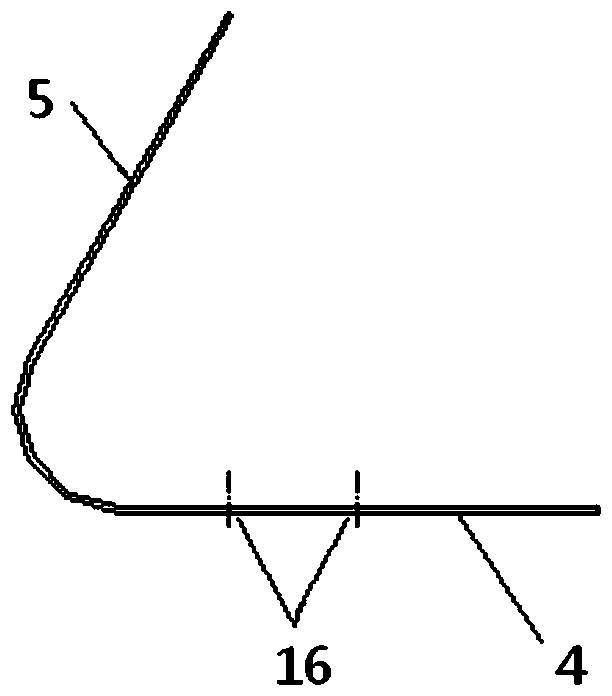

[0028] figure 2 It shows the double-layer aluminum plate 1 of the first embodiment of the present invention. It can be seen from the front that the honeycomb protrusions 2 are distributed on most of the aluminum plate surface, wherein the honeycomb protrusions are replaced by black lines, and the actual protrusions have a certain width so that The inner channel has a certain inner diameter. The honeycomb protrusions 2 correspond to the honeycomb channels inside the double-layer aluminum plate 1, and the honeycomb channels communicate with each other and at least one end 3 extends to the vicinity of the edge of the aluminum plate. Preferably, the honeycomb channel and the end portion 3 are far enough away from the edge so that the aluminum plate will not cut off the channel when the edge is cut according to design requirements.

[0029] A substantially circular blank area 20 is left in the center of the area where the honeycomb channel is located, and in this area, there is u...

no. 2 example

[0041] Figure 4A schematic diagram of a superconducting double-layer heat-dissipating aluminum plate according to the second embodiment of the present invention is shown. It can be seen from the front that the honeycomb protrusions 2' are distributed on most of the aluminum plate surface, and there is a blank area 20' inside the honeycomb area, and a plurality of straight channels 10' connecting the honeycomb structure are arranged in parallel in the blank area 20'. The honeycomb protrusion 2' corresponds to the honeycomb channel inside the double-layer aluminum plate 1', and the honeycomb channel is internally connected and at least one end 3' extends to the vicinity of the edge of the aluminum plate. Preferably, the honeycomb channel and the end portion 3 are far enough away from the edge so that the aluminum plate will not cut off the channel when the edge is cut according to design requirements. The method of manufacturing the heat dissipation aluminum plate of the secon...

no. 3 example

[0044] Figure 6 A schematic diagram of a superconducting double-layer heat-dissipating aluminum plate according to the third embodiment of the present invention is shown. On the front, you can see that the honeycomb-shaped protrusions 2" are distributed on most of the surface of the aluminum plate, and the center includes a blank area of 20". and figure 2 The line expression differs in that, Figure 6 Double lines are used to express honeycomb protrusions. The honeycomb protrusion 2" corresponds to the honeycomb channel inside the double-layer aluminum plate 1", and the honeycomb channel is internally connected and at least one end 3" extends to the edge of the aluminum plate. The heat dissipation aluminum plate of the third embodiment is made The method is the same as that of the first embodiment, and will not be repeated here.

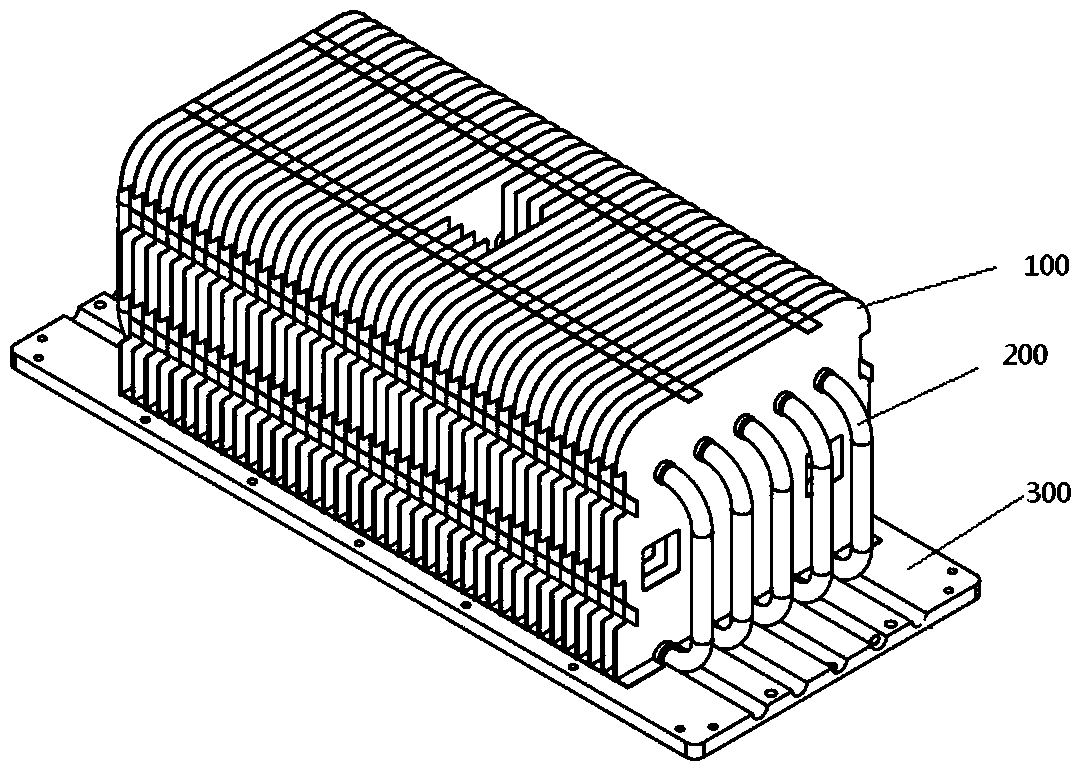

[0045] Figure 7 shows the use of Figure 6 Ultra-thin radiator made of superconducting double-layer heat-dissipating aluminum plate. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com