Dry-wet forming method and device for an artificial stone

A molding device and molding method technology, applied in the direction of molding pressure head, supply device, ceramic molding machine, etc., can solve the problems of long reuse time, poor decoration effect, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A kind of dry-wet molding method of artificial stone of the present invention is realized through the following steps:

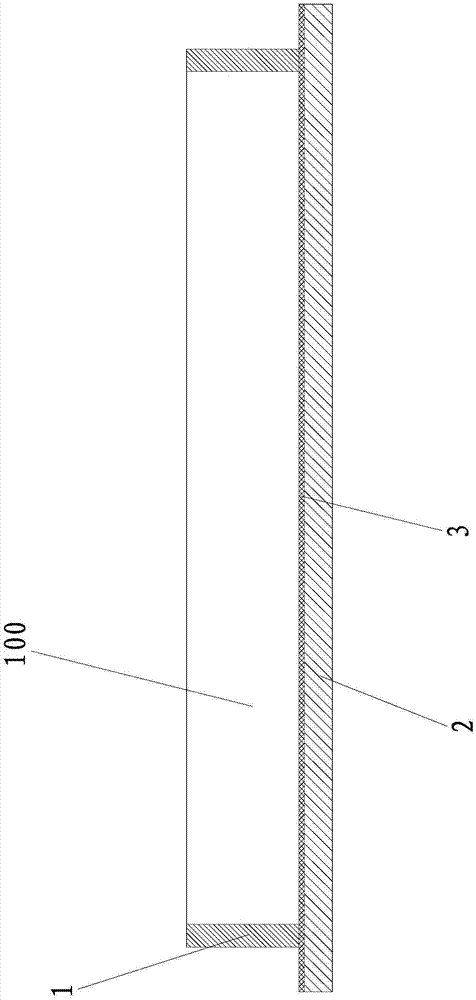

[0027] 1. Preparation of molding cavity: such as figure 1 As shown, the hollow side wall 1 is stacked on the bottom pallet 2 to form a molding cavity 100 whose upper end is open. The molding cavity 100 has a square structure, and the upper surface of the bottom pallet 2 has a rubber layer. 3. The side edge of the bottom support plate 2 is outside the hollow side wall 1;

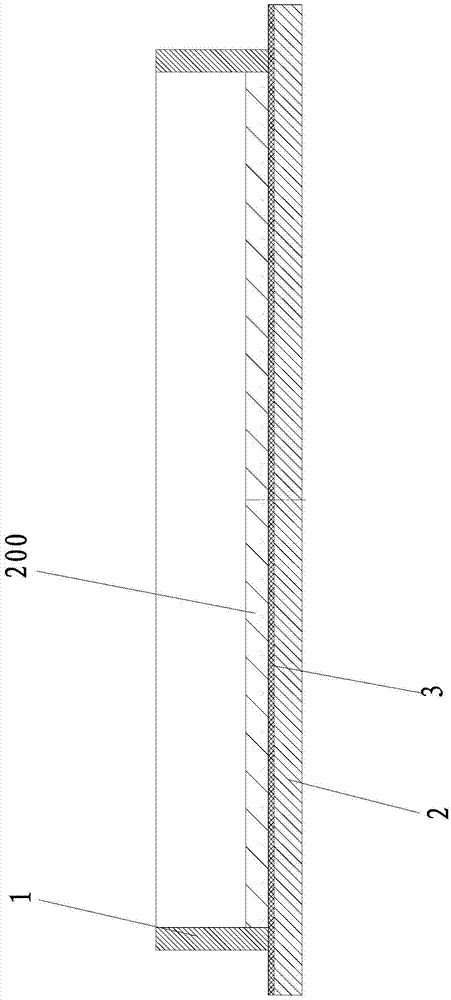

[0028] Second, the first feeding: such as figure 2 As shown, pour the cement slurry 200 into the molding cavity 100 in step 1, and stop pouring when the thickness of the cement slurry 200 in the molding cavity 100 reaches the required thickness. The optimal thickness of the cement slurry 200 is 1.5-3 cm;

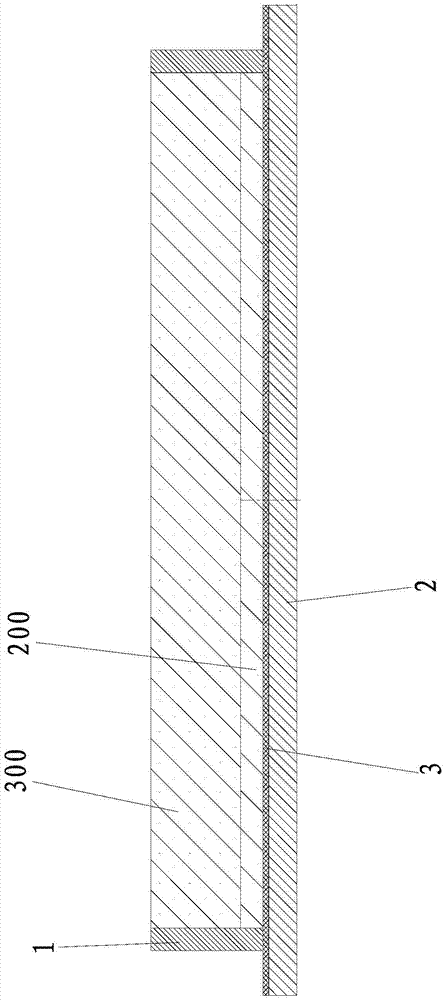

[0029] 3. The second feeding: if image 3 As shown, pour dry hard concrete 300 into the forming cavity of step 2 again, and stop pouring dry hard concrete 300 when the sum of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com