Uniform light key product manufacturing method and uniform light key product

A manufacturing method and button technology, applied in the direction of coating, etc., can solve problems such as uneven diffusion of gloss, and achieve high yield, environmentally friendly manufacturing process, and better effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

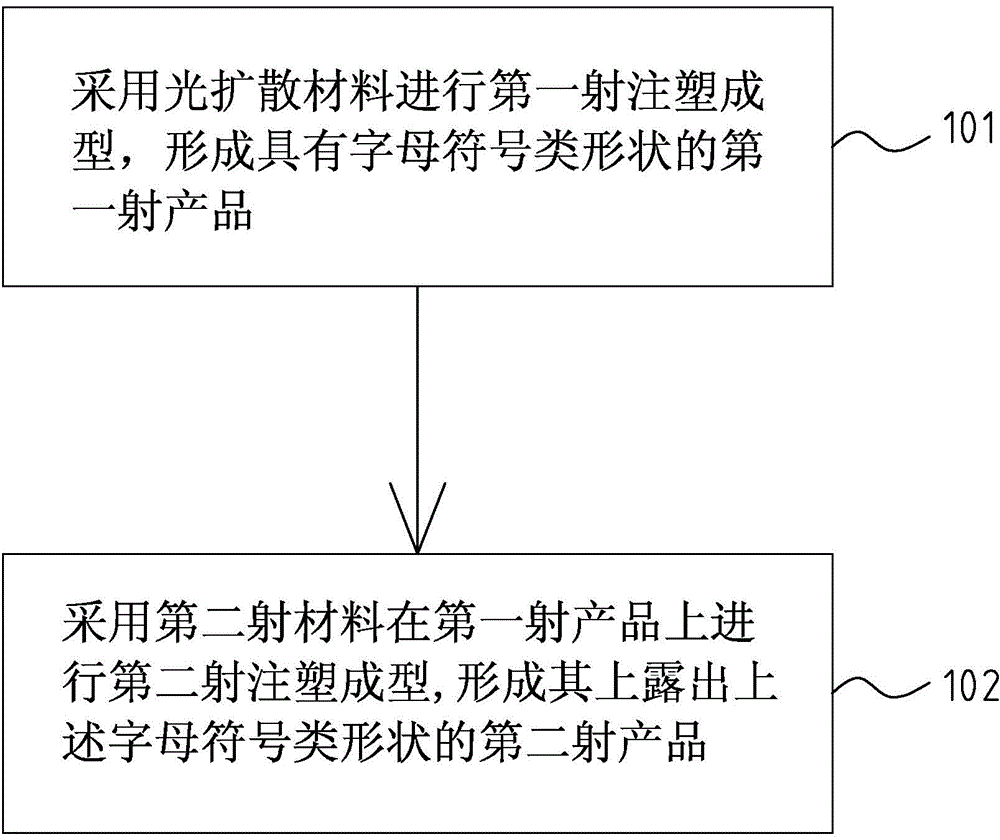

[0025] In order to have a further understanding of the purpose, method steps and effects of the present invention, the detailed description is as follows in conjunction with the accompanying drawings.

[0026] see figure 1 , figure 1 It is a flow chart of the manufacturing method of the uniform light button of the present invention.

[0027] In order to achieve the above object, the manufacturing method of the uniform light button of the present invention is used to manufacture a plastic button product with alphabetic characters, and the method comprises the following steps:

[0028] Step 101: Using the first shot material to perform first shot injection molding to form a first shot product, the first shot product has a shape of a letter symbol, and the first shot material is a light diffusion material;

[0029] Step 102: Carry out second injection molding on the first product by using the second material to form the second product, and the shape of letters and symbols on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com