Automatic board assembling method and system for goods delivered out of warehouse

A technology for cargo and board assembly, applied in the fields of aviation logistics and navigation, can solve problems such as restricting the development of the industry and improving service quality, inconsistency between the outgoing goods and pre-configured manifests, and waste of transportation carrier space, so as to realize the automatic operation of the whole process. , Fast speed, and the effect of improving the efficiency of disk assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

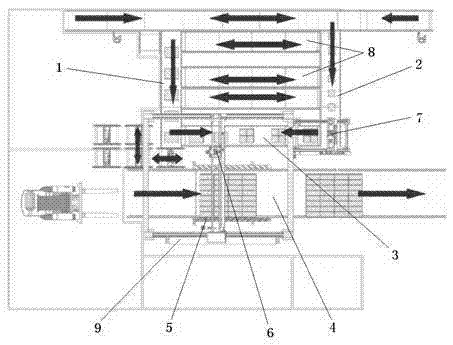

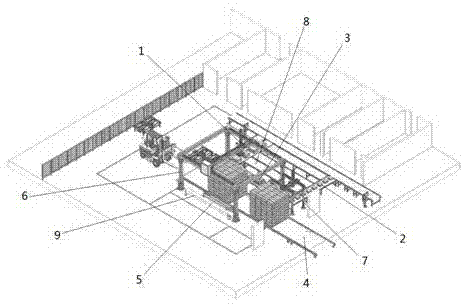

[0019] Embodiment of the present invention: the structural diagram of the automatic panel assembly system for out-of-cabin cargo is as follows figure 1 and figure 2 As shown, it includes two No. 1 conveyor lines 1 and No. 2 conveyor lines 2 arranged side by side. The ends of the No. 1 conveyor line 1 and No. 2 conveyor lines 2 are all docked with the cargo grabbing conveyor line 3. One side of the grabbing conveyor line 3 is provided with a panel cargo conveyor line 4, and at the same time, a lifting mechanism 5 is provided on the panel cargo conveyor line 4, and a rectangular coordinate robot 6 straddles the cargo grabbing conveyor line 3 and the panel cargo conveyor line 4 above. A small Cartesian robot 7 is also arranged at the junction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com