Universal automatic loading and unloading system based on bottom tooling separation method based on conveyor belt

A technology of automatic loading and unloading, conveyor belt, applied in the direction of conveyor, stacking of objects, destacking of objects, etc., can solve the problems of long feeding cycle time, poor processing continuity, and limited feeding quantity of single-piece products. The effect of high degree of automation, short running path and high transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

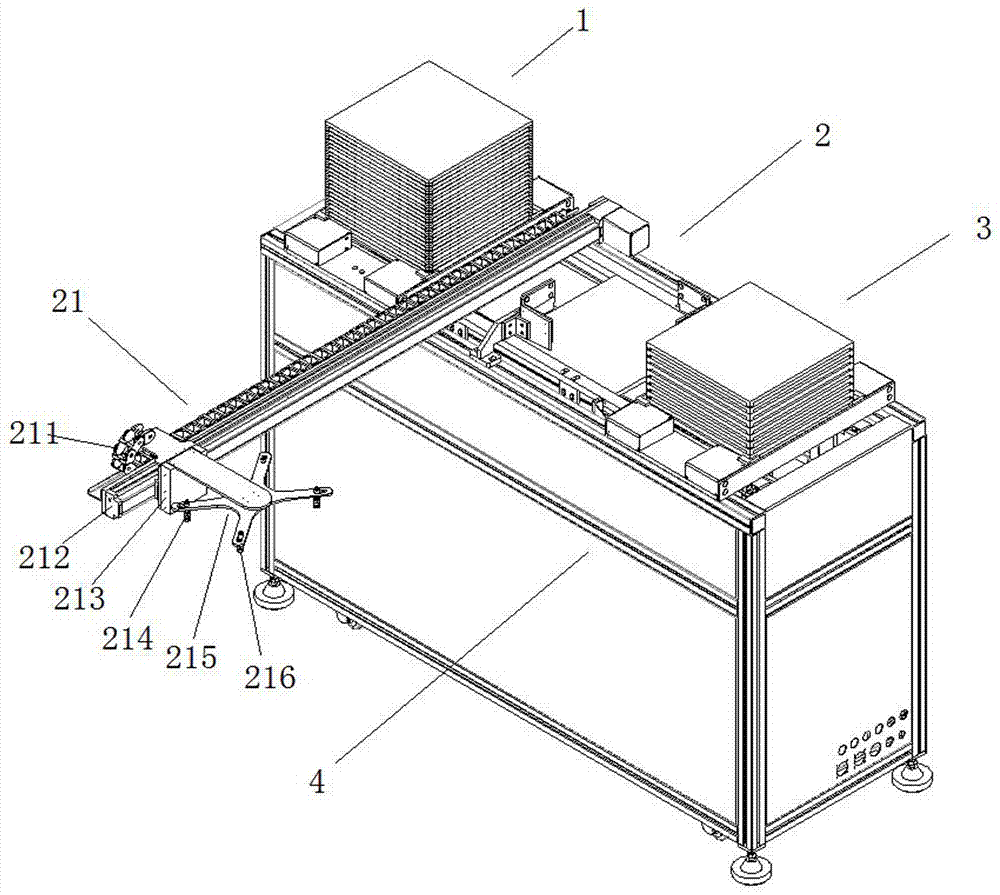

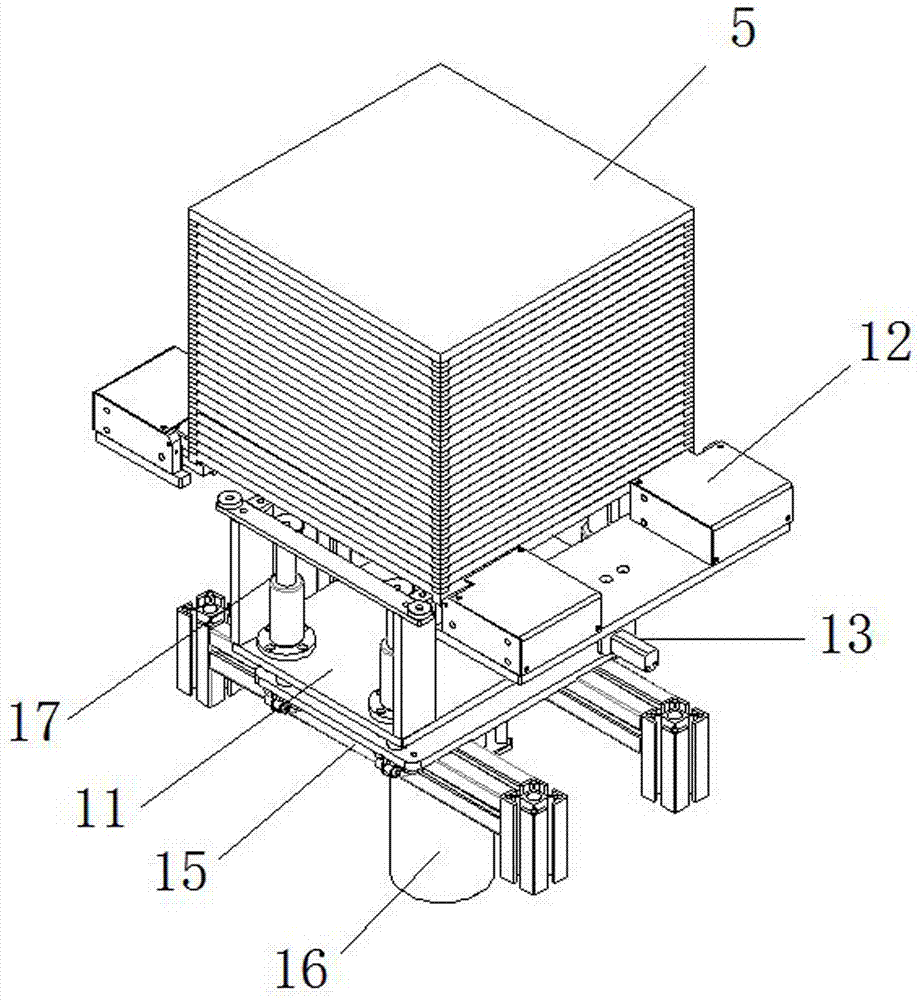

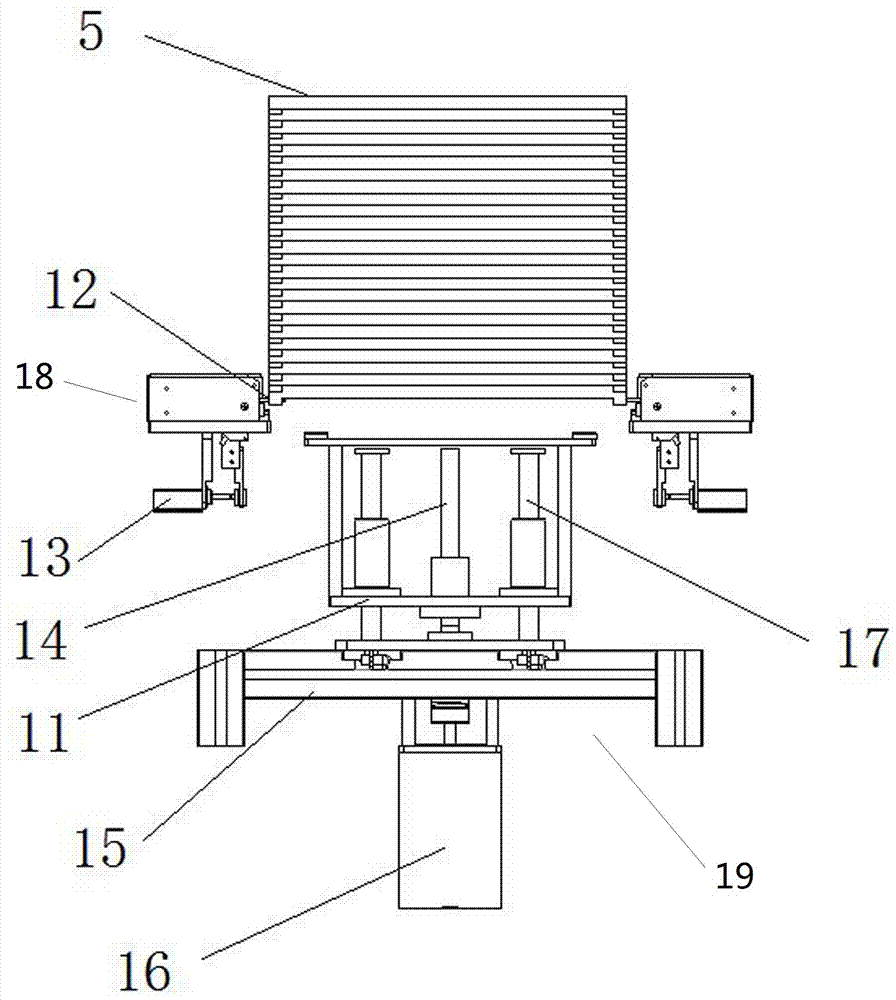

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021]For the loading and unloading process, there are two implementation schemes: one is the automatic loading and unloading module based on the top tooling separation method; the other is the loading and unloading module based on the bottom tooling separation method. The invention is a loading and unloading system based on the bottom frock separation method. Compared with the automatic loading and unloading method based on the top tooling separation method, the loading and unloading method based on the bottom tooling separation method has the following characteristics:

[0022] 1. Pallet separation is achieved by separating the bottom of the pallet. This method can insert any number of products into the stack of products to be processed during the processing process, improving the continuity of the processing process;

[0023] 2. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com