Water-based ceramic anticorrosive coating containing aluminum phosphate as well as preparation and curing methods thereof

A technology of aluminophosphate and anti-corrosion coatings, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of lack of commercial application of aluminophosphate coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

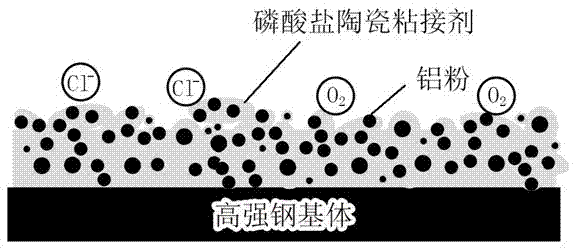

Method used

Image

Examples

example 1

[0024] Mix 1000 parts of aluminum dihydrogen phosphate with 1200 parts of distilled water to form a uniform solution, add 60 parts of tetraethyl orthosilicate, and stir with magnetic stirring under sealed conditions until the tetraethyl orthosilicate is completely hydrolyzed and forms a clear solution. Then add 8 parts of zinc oxide and 10 parts of magnesium oxide, stir continuously to dissolve them completely, add 28 parts of magnesium chromate, mix evenly, add 45 parts of micronano aluminum powder and disperse evenly, and the coating is prepared. The paint was sprayed onto the polished steel plate by air spraying, dried in an oven at 120°C for 2 hours, and then heated to 200°C for 17 hours to prepare the coating.

[0025] Example 1 formula coating test performance is as follows:

[0026] (1) In the neutral salt spray test, rust spots appeared on the surface of the coating after 1008 hours of neutral salt spray test

[0027] (2) Under the high-temperature oxidation test con...

example 2

[0029] Mix 1300 parts of aluminum dihydrogen phosphate with 1000 parts of distilled water to form a uniform solution, add 40 parts of tetraethyl orthosilicate, and stir with magnetic stirring under sealed conditions until the tetraethyl orthosilicate is completely hydrolyzed and forms a clear solution. Then add 9 parts of zinc oxide and 9 parts of magnesium oxide, stir continuously to dissolve them completely, add 24 parts of magnesium chromate, mix evenly, add 48 parts of micronano aluminum powder and disperse evenly, and the coating is prepared. The paint was sprayed onto the polished steel plate by air spraying, dried in an oven at 120°C for 2 hours, and then heated to 200°C for 17 hours to prepare the coating.

[0030] Example two formula paint test performance is as follows:

[0031] (1) In the neutral salt spray test, rust spots appeared on the surface of the coating after 960 hours of neutral salt spray test;

[0032] (2) Under the high-temperature oxidation test cond...

example 3

[0034] Mix 1500 parts of aluminum dihydrogen phosphate with 1100 parts of distilled water to form a uniform solution, add 20 parts of tetraethyl orthosilicate, and stir with magnetic stirring under sealed conditions until the tetraethyl orthosilicate is completely hydrolyzed and forms a clear solution. Then add 10 parts of zinc oxide and 8 parts of magnesium oxide, stir continuously to dissolve them completely, add 30 parts of magnesium chromate, mix well, add 50 parts of micronano aluminum powder and disperse evenly, and the coating is prepared. The paint was sprayed onto the polished steel plate by air spraying, dried in an oven at 120°C for 2 hours, and then heated to 200°C for 17 hours to prepare the coating.

[0035] Example three formula paint test performance is as follows:

[0036] (1) In the neutral salt spray test, obvious rust spots appeared on the surface of the coating after 1104 hours of neutral salt spray test;

[0037] (2) Under the high-temperature oxidation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidative weight gain | aaaaa | aaaaa |

| Oxidative weight gain | aaaaa | aaaaa |

| Oxidative weight gain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com