Long-span deformed steel truss and floor steel structure installation and construction method

A floor-to-ceiling steel structure and special-shaped steel technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of complex building layout and difficult travel of large-tonnage cranes, and achieve easy assembly on site and increase spatial stability. , the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

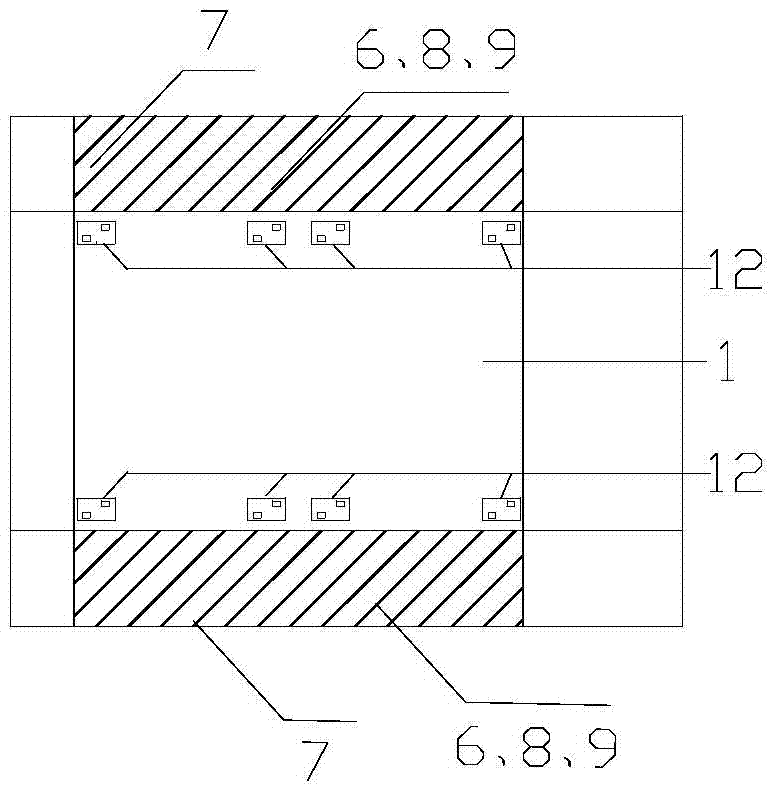

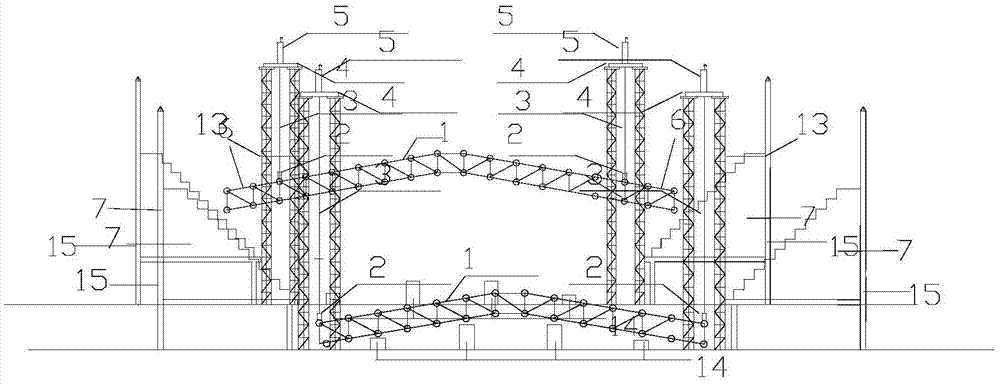

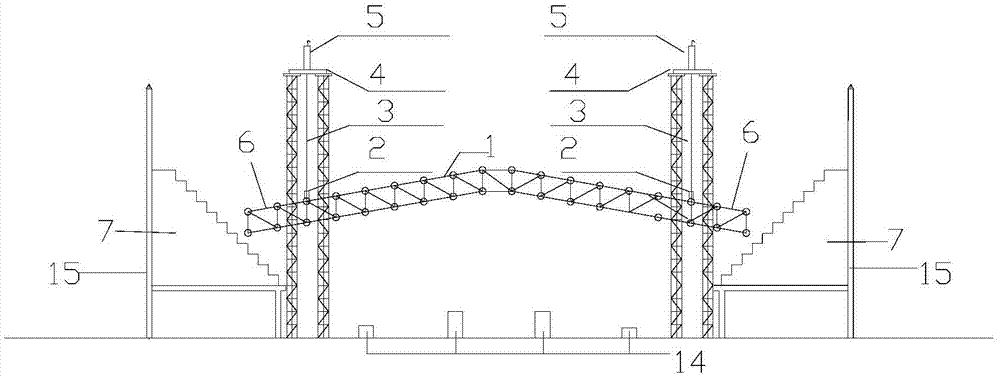

[0056] (1) Build a plurality of lifting frame foundations 12 at intervals along the inner sides of the ladder stands 7 on the left and right sides of the gymnasium that are symmetrically arranged and along the direction parallel to the ladder stands 7, and then install steel on each of the lifting frame foundations 12. Structure lifting frame 13, then on described steel structure lifting frame 13, lifting frame platform 4 is installed;

[0057] (2) lifter 5 is installed on described lifting frame platform 4, and steel strand 3 is connected at the lower end of described lifter 5;

[0058] (3) Temporary towers 14 are installed on the ground of the first lifting block unit 1 between the ladder stands 7 on both sides, and the first lifting block unit 1 of the main frame is assembled on the temporary towers. The distance between the left and right ends of the lifting block unit 1 is less than the distance between the inner sides of the stepped stands 7 on both sides, and the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com