Mixed communication type oil-gas shock attenuation device

A shock absorber and hybrid communication technology, which is applied in the direction of shock absorbers, gas-hydraulic shock absorbers, spring/shock absorbers, etc., can solve the problem of not being able to improve the ride comfort of the vehicle and the high sealing performance of the accumulator , High production cost of oil and gas damper, to achieve the effect of improving vertical vibration performance, saving installation space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

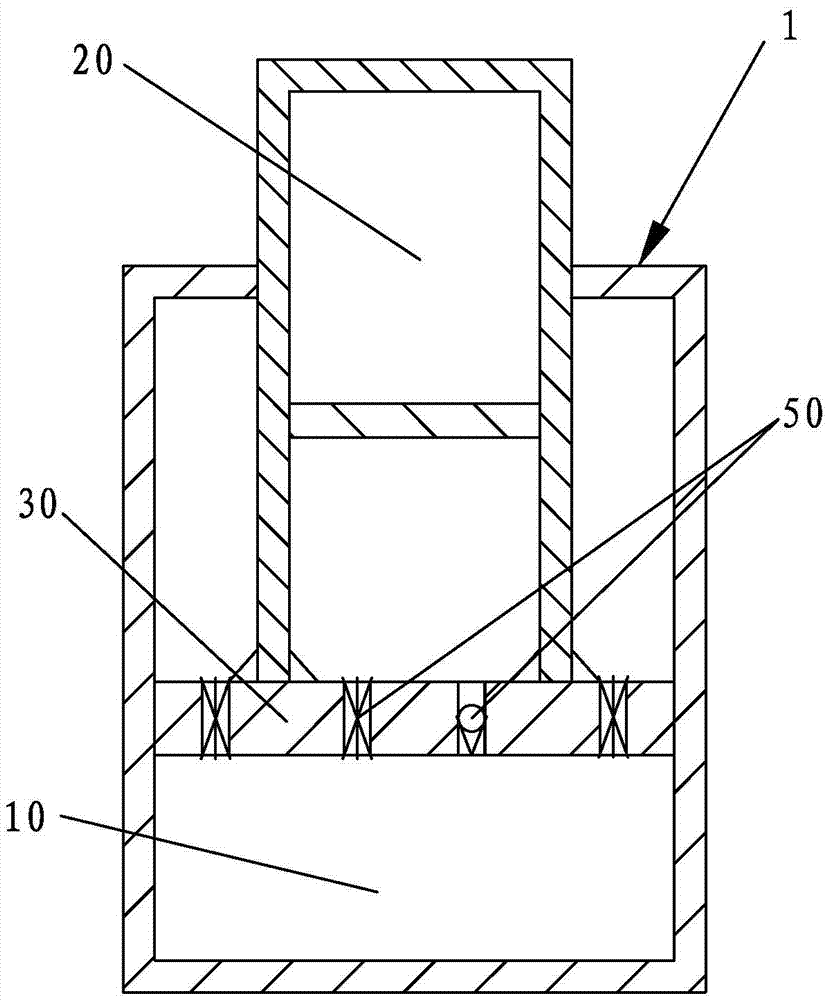

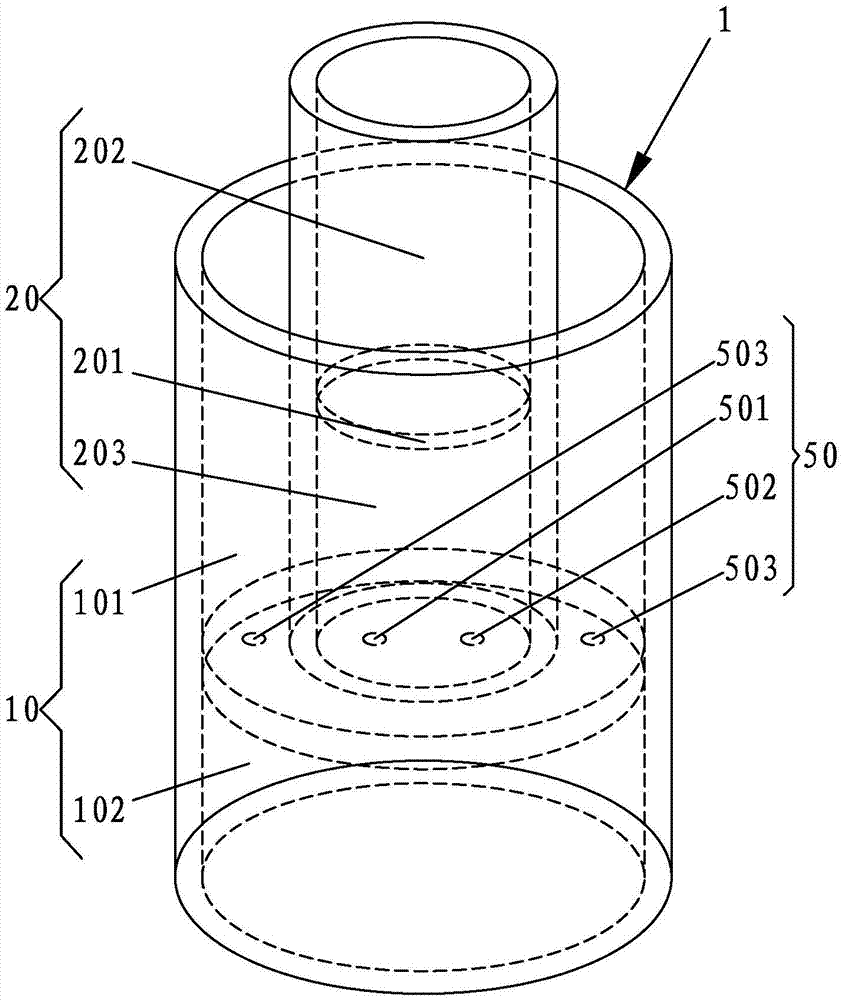

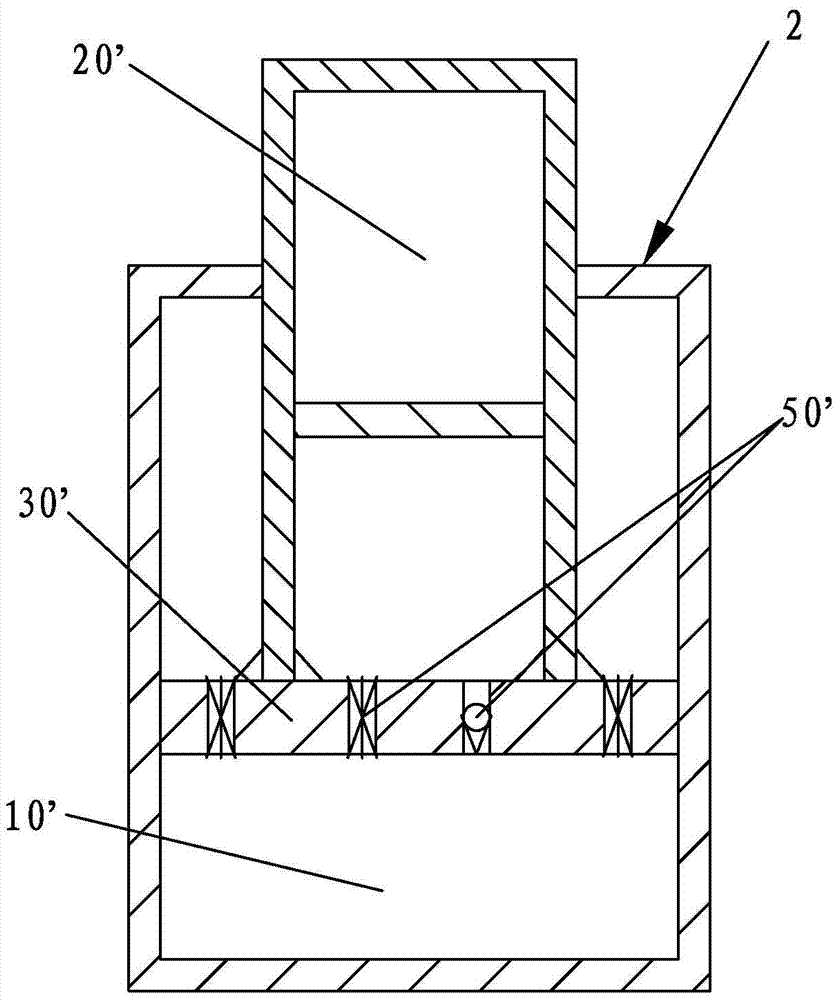

[0053] Such as figure 2 with Figure 4 As shown, the first piston 30 of the first oil-pneumatic damping device 1 is provided with a second damping hole 503 for communicating with the upper chamber 101 of the first hydraulic cylinder chamber and the lower chamber 102 of the first hydraulic cylinder chamber. Similarly, the second piston 30' of the second oil-gas damping device 2 is provided with a fourth damping hole 503' for communicating with the upper chamber 101' of the second hydraulic cylinder chamber and the lower chamber 102' of the second hydraulic cylinder chamber.

[0054] Preferably, the first damping hole 501, the first check valve 502, the third damping hole 501' and the third check valve 502' are all one.

[0055] Preferably, both the second damping hole 503 and the fourth damping hole 503' are two.

[0056] Concrete working principle of the present invention is as follows:

[0057] When the cylinder body of the first cylinder chamber 20 of the first oil-pneum...

Embodiment 2

[0069] Such as Figure 5 with Image 6As shown, the first piston 30 of the first oil-pneumatic damping device 1 is provided with a second one-way valve 504 for communicating with the upper chamber 101 of the first hydraulic cylinder chamber and the lower chamber 102 of the first hydraulic cylinder chamber. Similarly, the second piston 30' of the second oil-gas damping device 2 is provided with a fourth one-way valve 504' for connecting the upper chamber 101' of the second hydraulic cylinder chamber with the lower chamber 102' of the second hydraulic cylinder chamber. .

[0070] Preferably, the first damping hole 501, the first check valve 502, the third damping hole 501' and the third check valve 502' are all one.

[0071] Preferably, both the second one-way valve 504 and the fourth one-way valve 504' are two.

[0072] In this embodiment, the hybrid connected oil-gas damping device of the present invention improves the disadvantages of the existing traditional oil-gas dampe...

Embodiment 3

[0074] Such as Figure 7-8 As shown, an inert gas is installed in the upper chamber 101 of the first hydraulic cylinder chamber of the first oil-gas damping device 1, and the inert gas is high-pressure nitrogen; the second hydraulic cylinder chamber of the second oil-gas damper device 2 An inert gas is installed in the upper chamber 101', and the inert gas is high-pressure nitrogen. Similarly, the upper chamber 101 of the first hydraulic cylinder chamber of the first oil-pneumatic damping device 1 and the upper chamber 101' of the second hydraulic cylinder chamber of the second oil-pneumatic damping device 2 are both sealed cavities, and the first An upper chamber 101 of a hydraulic cylinder chamber is not connected to the lower chamber 102 of the first hydraulic cylinder chamber, and the upper chamber 101' of the second hydraulic cylinder chamber is not communicated to the lower chamber 102' of the second hydraulic cylinder chamber.

[0075] In this example, if Figure 7-8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com