Natural gas high-pressure ball valve life test apparatus

A life test device, high-pressure ball valve technology, applied in the direction of measuring device, mechanical component testing, machine/structural component testing, etc. The effect of small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

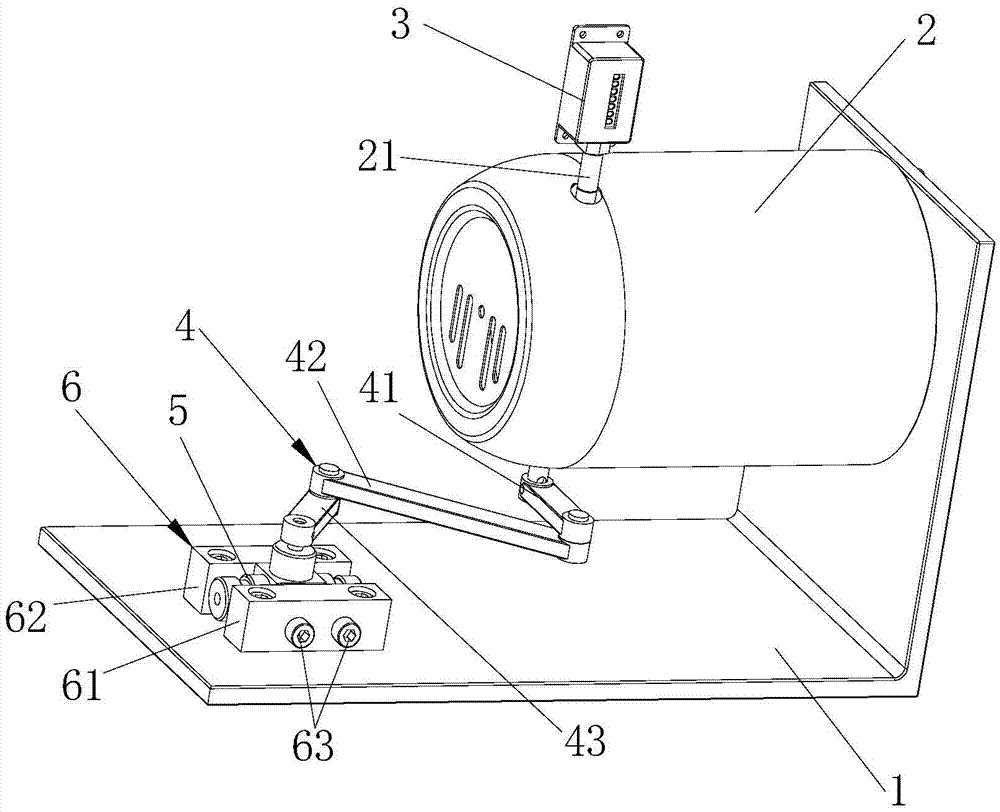

[0024] Such as figure 1 As shown, the natural gas high-pressure ball valve life test device includes a fixed frame 1, a drive motor 2, a counter 3, a transmission mechanism 4 and a clamp mechanism 6 for clamping the high-pressure ball valve 5, and the clamp mechanism 6 is installed on the fixed frame 1. One end, the drive motor 2 is installed on the other end of the fixed frame 1, the counter 3 is installed on one end of the power output shaft 21 of the drive motor 2, and the other end of the power output shaft 21 of the drive motor 2 passes through the transmission mechanism 4 Connect with high pressure ball valve 5. The structure is simple, and the counter 3 can accurately record the number of rotations of the power output shaft 21, thus ensuring the accuracy of the life test results.

[0025] The fixing frame 1 is in an overturned "L" shape. Such as figure 1 , the fixing frame 1 is plate-shaped, and this structure has good stability to ensure that the test can be carried...

Embodiment 2

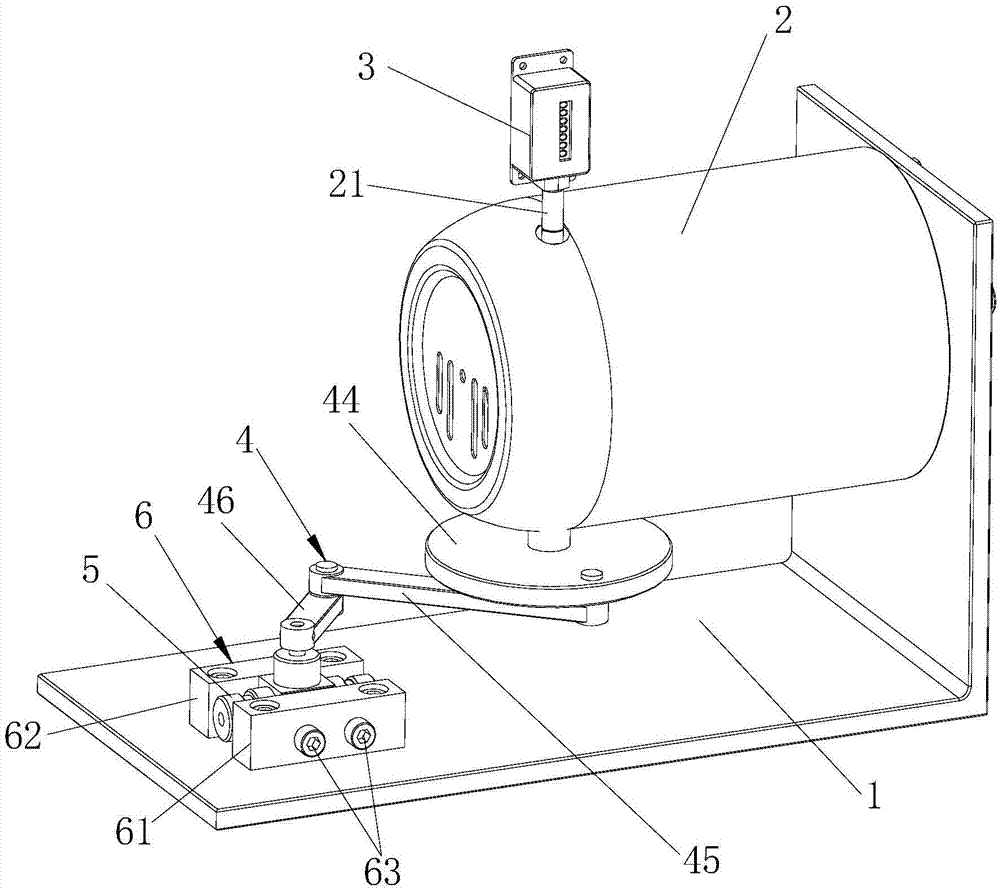

[0030] This natural gas high-pressure ball valve life test device is the same as embodiment 1 except the following technical features: as figure 2 As shown, the transmission mechanism 4 includes an eccentric wheel 44, a fourth connecting rod 45 and a fifth connecting rod 46, the eccentric wheel 44 is installed on the other end of the power output shaft 21 of the drive motor 2, and the eccentric wheel 44 One end is connected to one end of the fourth connecting rod 45 , the other end of the fourth connecting rod 45 is connected to one end of the fifth connecting rod 46 , and the other end of the fifth connecting rod 46 is connected to the high pressure ball valve 5 . This implementation adopts the transmission mechanism 4 with a structure different from that of Embodiment 1, which can also ensure the effectiveness and stability of the transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com