Slag actual ingredient performance detection method for slag containing volatile components

A detection method and a technology of slag, applied in the direction of weighing by removing certain components, can solve problems such as the influence of accuracy, and achieve the effect of having reference value and accurate results of slag performance measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dephosphorization slag containing sodium oxide, slag basic composition, melting point and weight loss measurement results are shown in Table 2. The sodium oxide in the sample is added in the form of sodium carbonate, the melting point is determined by the hemispherical melting point method, and the weight loss is measured by placing the sample in a crucible, hanging it for heating, and continuously measuring its weight change.

[0027] According to relevant research, the weight loss above 800°C is mainly caused by the volatilization of sodium oxide. The slag composition obtained after sodium oxide volatilization is shown in Table 3. That is to say, the corrected slag composition in Table 3 is the true composition of the slag corresponding to the measured melting point.

[0028] Table 2 Different dephosphorization slag components (%wt, mass percentage), melting point and weight loss measurement results

[0029]

[0030] Similarly, in the test of measuring slag visco...

Embodiment 2

[0033] During the reduction process of high-lead slag, with the change of the content of lead oxide and zinc oxide in the slag, the composition of the slag will continue to change, and then the properties of the slag will also be in constant change. Understanding the properties of slag is important for process control.

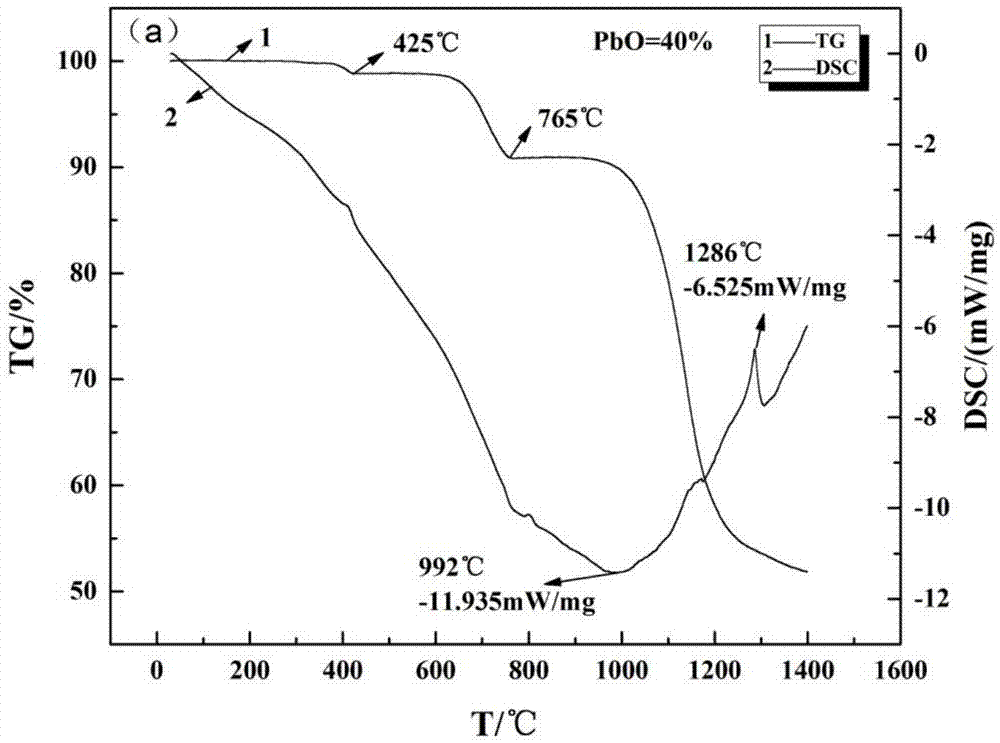

[0034] For the reduction process of high-lead slag, if the amount of zinc oxide, calcium oxide, silicon dioxide and ferrous oxide remains unchanged, the composition of the slag will change as shown in Table 4 with the reduction of lead oxide. The sample was analyzed by thermogravimetric-differential thermal device, and the results were as follows: figure 1 shown. The weight loss rate in each temperature range was measured and calculated, and the analysis results are shown in Table 5.

[0035] The slag composition (%wt, mass percentage) of the different lead reduction degree of table 4 preparation

[0036]

[0037] After analysis, it is considered that th...

Embodiment 3

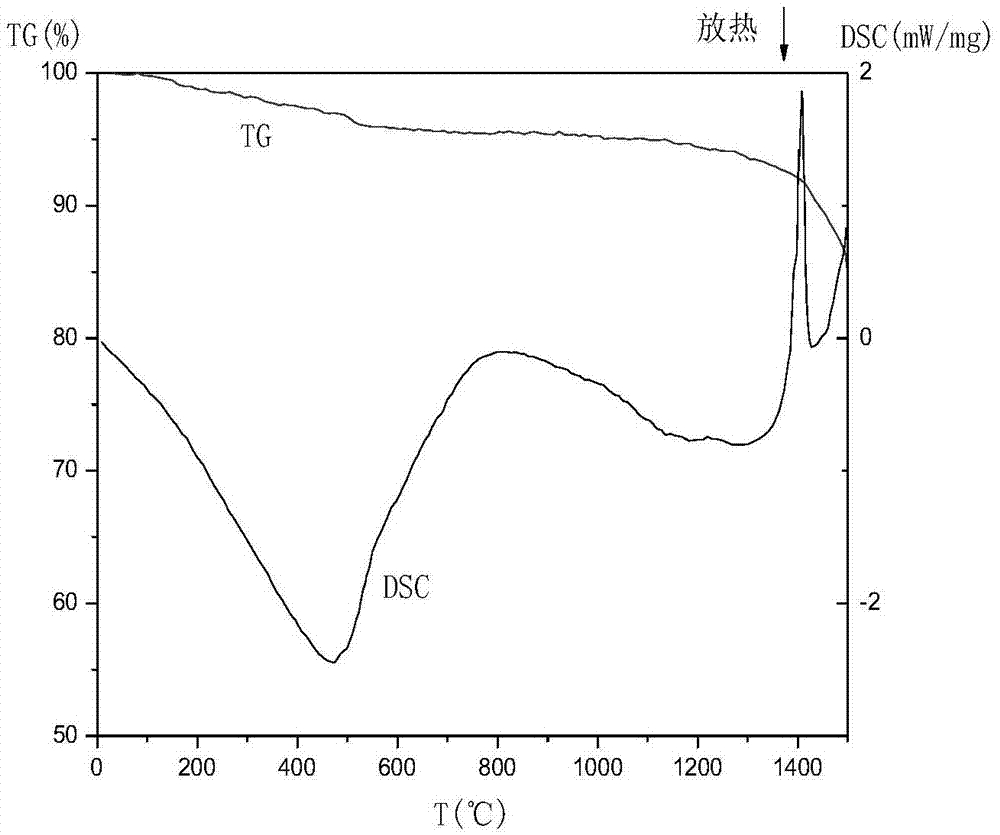

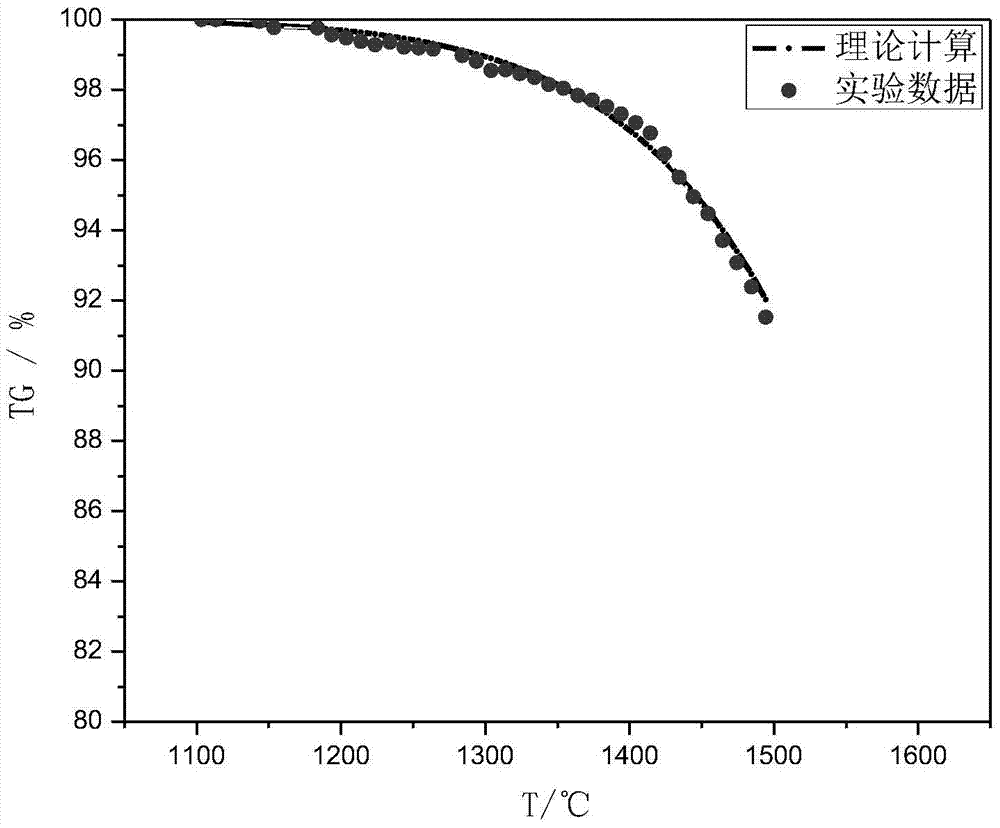

[0041] ANF-6 slag for electroslag remelting, the specific composition is 70% CaF 2 -30%Al 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com