A low-impedance high-voltage coaxial cable

A coaxial cable, low-impedance technology, applied in pulse signal transmission and high-voltage square wave pulse generation, low-impedance coaxial cable, low-impedance high-voltage coaxial cable field, can solve the problem that high-voltage coaxial cables are large in size and cannot meet compact requirements Problems such as high-power pulse power device and large turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

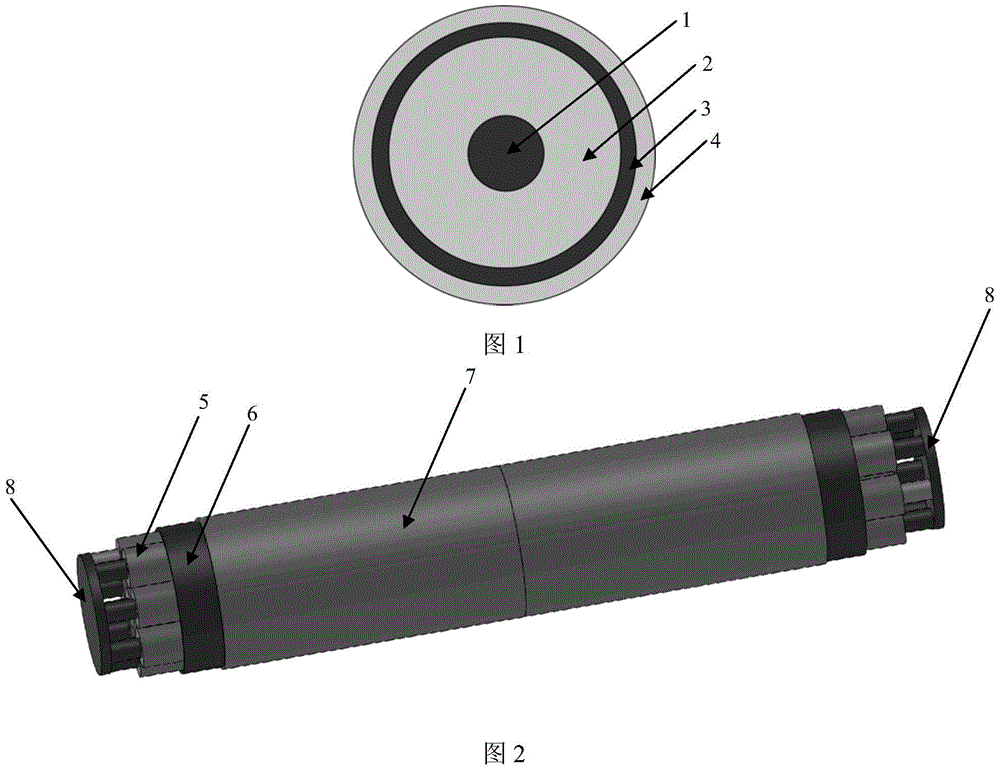

[0037] figure 1 For the background technology [Chen Guoping, Luo Yikun, "Preparation of Low Impedance Coaxial Cable and Test Method for Adjustable Resistance", Digital Communication, 2014, Vol.41, No.6, pp.1-2] The section of traditional coaxial cable Schematic diagram, as can be seen from the figure, the traditional coaxial cable is mainly composed of a single metal inner conductor 1, inner insulation layer 2, metal outer conductor 3 and outer insulation layer 4, in order to meet the requirements of the working voltage, it is necessary to reduce the impedance Increasing the diameters of the metal inner conductor 1, the inner insulating layer 2, the metal outer conductor 3 and the outer insulating layer 4 results in a larger turning radius of the high-voltage coaxial cable.

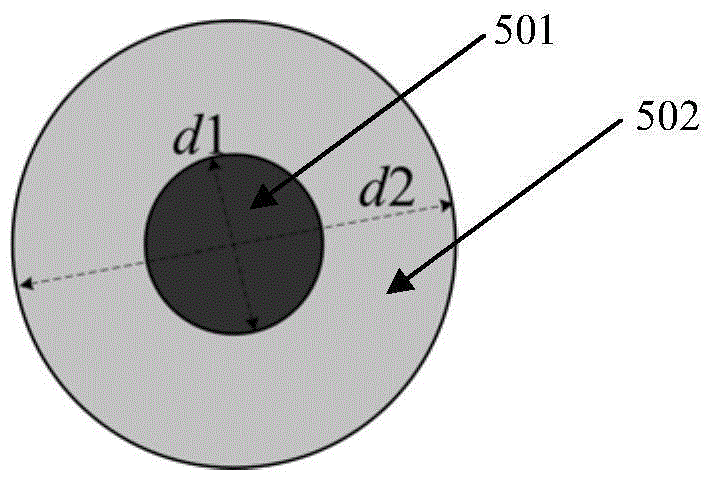

[0038] figure 2 It is a three-dimensional structure diagram of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com