A three-dimensional conveying device of a photovoltaic battery string automatic typesetting machine

A technology of conveying device and typesetting machine, which is applied in the direction of conveyor objects, transportation and packaging, circuits, etc., which can solve the problems of uncontinuable follow-up processes, large floor area, and low production efficiency, so as to facilitate mutual connection and conversion, occupy The effect of small space and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

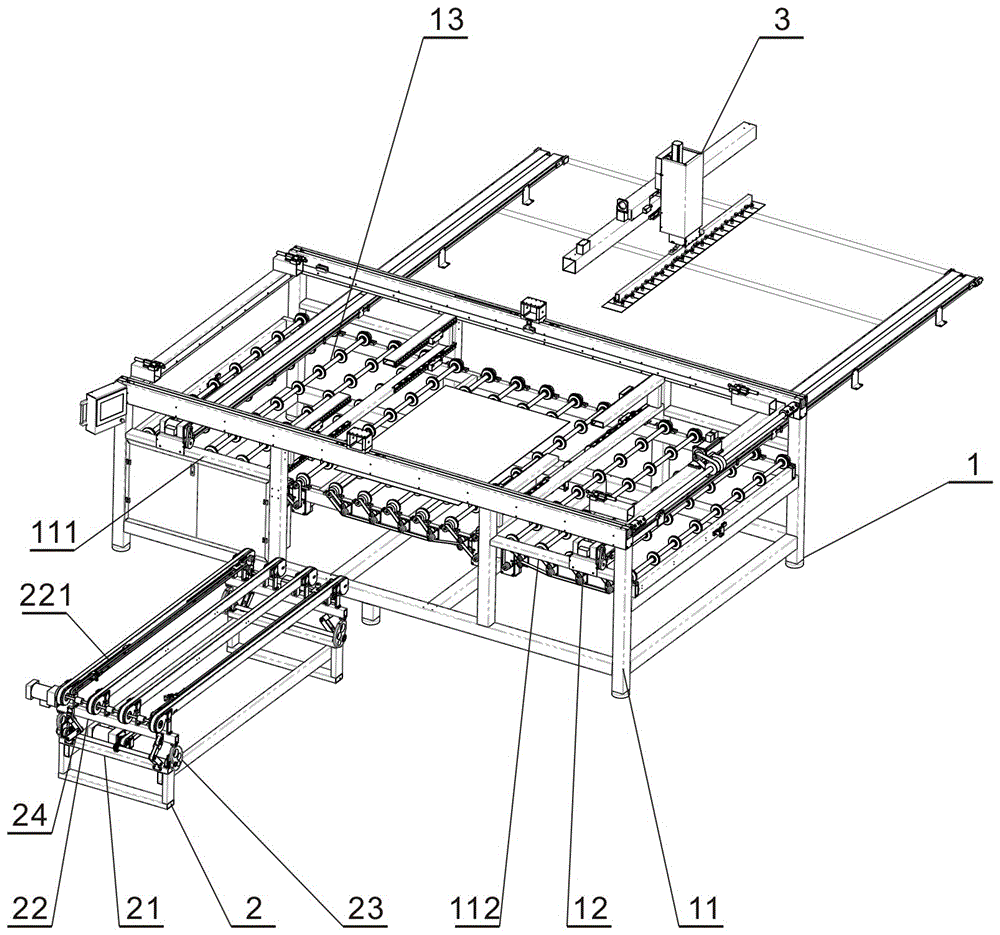

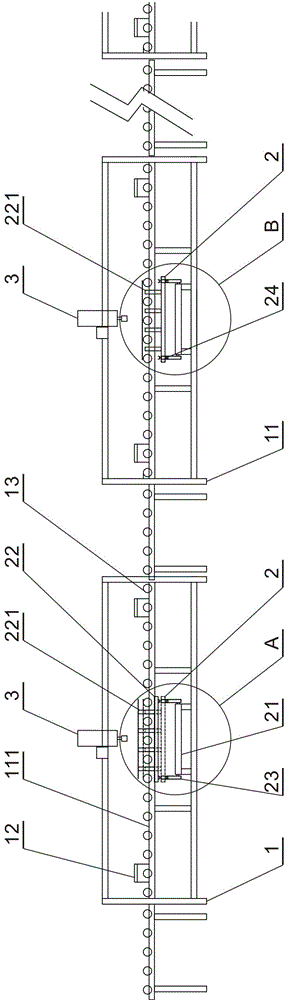

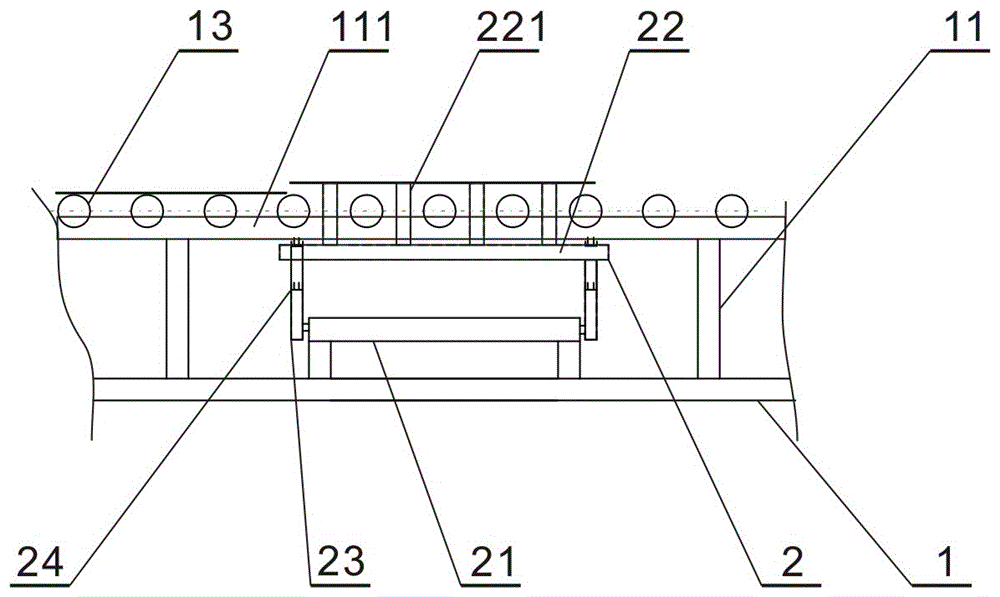

[0018] The setting of longitudinal conveying line and working platform of the present invention:

[0019] refer to figure 1 , figure 2 , Figure 5 , according to the plane layout design, a plurality of conveying frames 11 are connected in series to form a longitudinal conveying line 1, and two working platforms 2 are arranged on two different stations of the conveying frame 11 in the longitudinal conveying line 1, and the two The automatic typesetting machine 3 is set corresponding to the two stations of the working platform 2, and is connected with the conveying frame 11; at this time, the two working platforms 2 and the two automatic typesetting machines 3 form a longitudinal conveying line with two stations 1.

[0020] The working process of the longitudinal conveying line provided by the multi-station of the present invention:

[0021] refer to figure 1 , figure 2 , image 3 , Figure 4 , taking the work of the first station as an example, when the glass is drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com