Method and apparatus for manufacturing group 13 nitride crystal

A nitride crystal and melt technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of enhanced adverse effects, increased crystal size, difficulty in manufacturing high-quality, large-sized crystals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

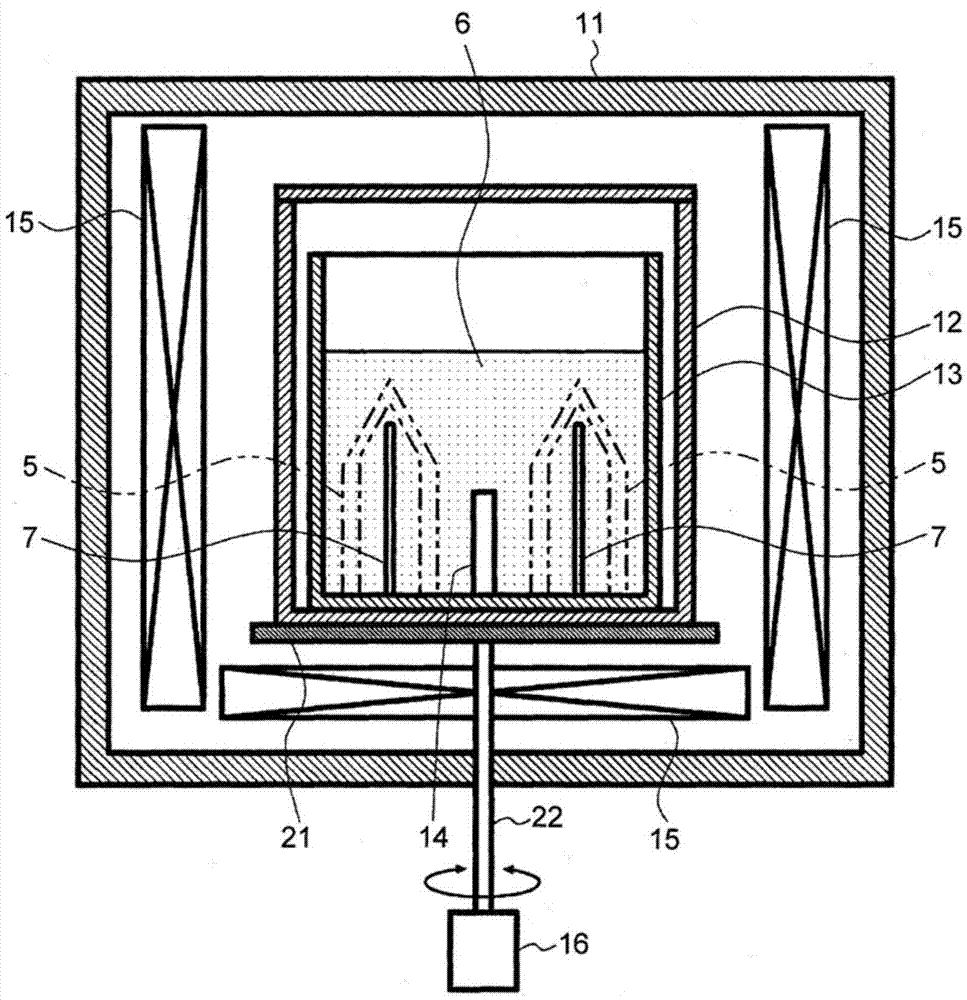

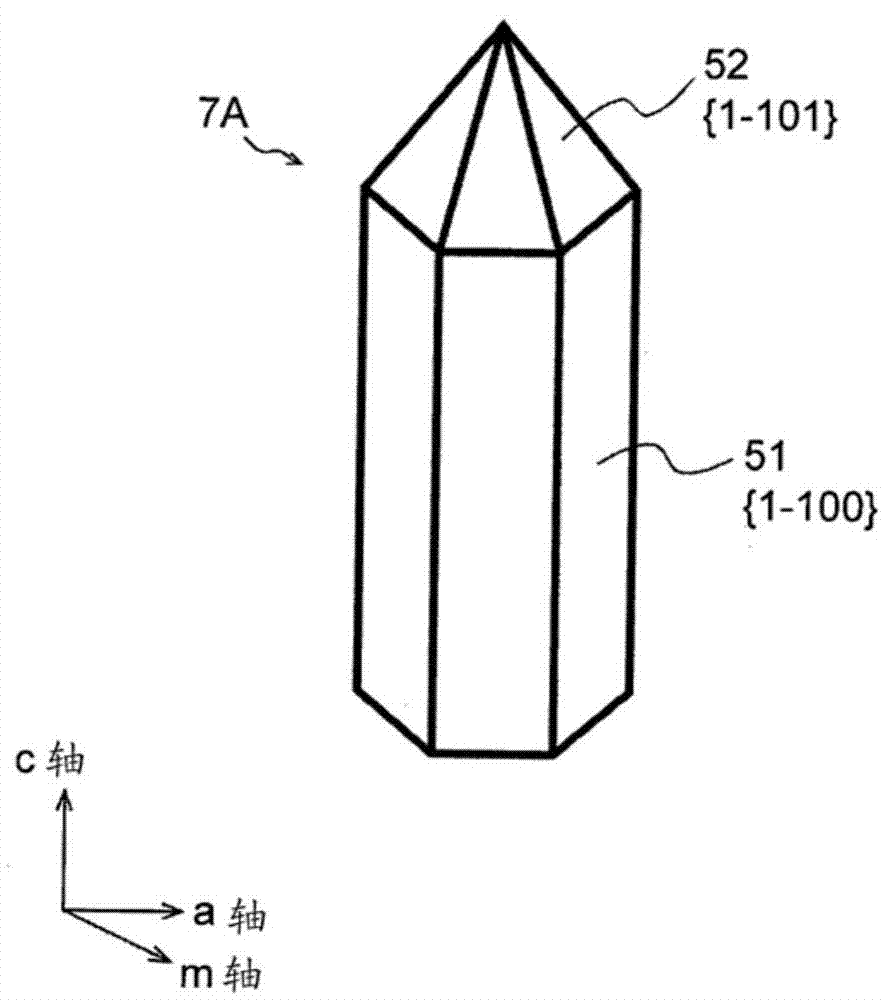

[0063] In the present embodiment, a gallium nitride (GaN) crystal which is a group 13 nitride crystal is grown under the following conditions in which Figure 9 and 10 As illustrated in , the seed crystal 7 and the structure 14A are placed. First, the image 3 The columnar seed crystal 7A made of GaN explained in was set in a reaction vessel 13 made of alumina in a glove box with a high-purity Ar atmosphere. The seed crystal 7A is inserted into a hole formed in the bottom of the reaction vessel 13 to be fixed (held).

[0064] Next, sodium (Na) liquefied by heating is put into the reaction vessel 13 as a mixed melt (solvent) 6 . After the sodium solidifies, gallium (Ga) and carbon are put therein. Set the molar ratio between gallium and sodium at 0.25:0.75. The carbon content was set at 0.5% relative to the total moles of gallium, sodium, and carbon.

[0065] Thereafter, the reaction container 13 was installed in the inner container 12 , and the inner container 12 was tak...

Embodiment 2

[0070] In this embodiment, the GaN crystal 5 is grown under the following conditions: where Figure 11 and 12 As explained in , the seed crystal 7 and the structure 14B are placed. The four columnar structures 14B are arranged point-symmetrically with respect to the central axis 61 of the reaction vessel 13 . Specifically, the structures 14B and the seed crystal 7 are placed at positions having fourfold symmetry with the central axis 61 as the center of symmetry. Four columnar seed crystals 7A are placed at the center of each structure body 14B. The seed crystal 7A is inserted into the hole formed in the structural body 14 to be fixed. Other crystal growth conditions and rotation conditions were the same as those of Example 1.

[0071] In this configuration, even when the size of GaN crystal 5 is increased to such an extent that GaN crystal 5 itself similarly functions as structure 14B, it does not change the fact that vertical flow is generated in mixed melt 6 . A vertic...

Embodiment 3

[0074] In this embodiment, GaN crystal 5 is grown in a manner similar to that of Embodiment 2, except that Figure 17 other than the rotary controls described in . Such as Figure 11 and 12 As illustrated, the seed crystal 7 and the structure 14B are placed in the reaction vessel 13 . For the rotation control of the rotary rod 22 that rotates the reaction vessel 13, as Figure 17 The rotation method described in uses a loop consisting of acceleration, rotation, deceleration, and stop, followed by acceleration, rotation, deceleration, and stop in the opposite direction of the immediately preceding rotation. This cycle was repeated for 1000 hours at a rotation speed of 15 rpm to allow the crystals to grow.

[0075] By reversing the direction of rotation in this way, the concentration distribution of the dissolved substance in the mixed melt 6 is further uniformed, and a more uniform GaN crystal 5 can be produced.

[0076] Through the crystal growth process, it is possible t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com