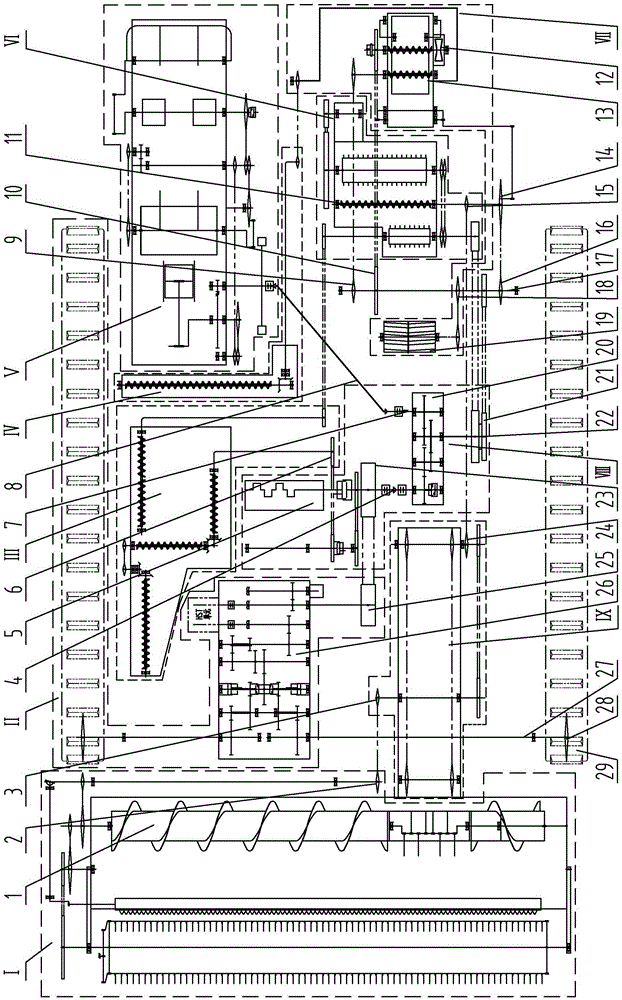

Complete machine transmission scheme for rice-wheat combine harvesting and bundling machine

A baler, rice and wheat technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high manual collection costs, high labor intensity, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0010] The power system (Ⅷ) and walking system (II) of the rice-wheat combine harvester baler transmit power to the HST gearbox assembly through the belt transmission between the power output pulley (23) and the gearbox input pulley (25). into (26), the driving half shaft (27) of the HST gearbox assembly (26) drives the driving wheel (28) to rotate, thereby driving the crawler belt (29) to rotate, and realizing the walking function of the harvester; the power system (Ⅷ) and The granary system (Ⅲ) realizes the automatic grain unloading function of the harvester granary system (Ⅲ) through the belt transmission between the power output pulley (23) and the granary input pulley (6); the engine assembly of the power system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com