Grating roller surface circumference dividing machine

A roll surface and engraving machine technology, which is applied to metal processing machinery parts, turning equipment, feeding devices, etc., can solve the problems of poor structural rigidity of machine tools, difficult elimination of vibration ripples, and difficulty in realizing high-precision grating roll processing, etc., to achieve improvement Improvement of machining efficiency and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment, the present invention is described further.

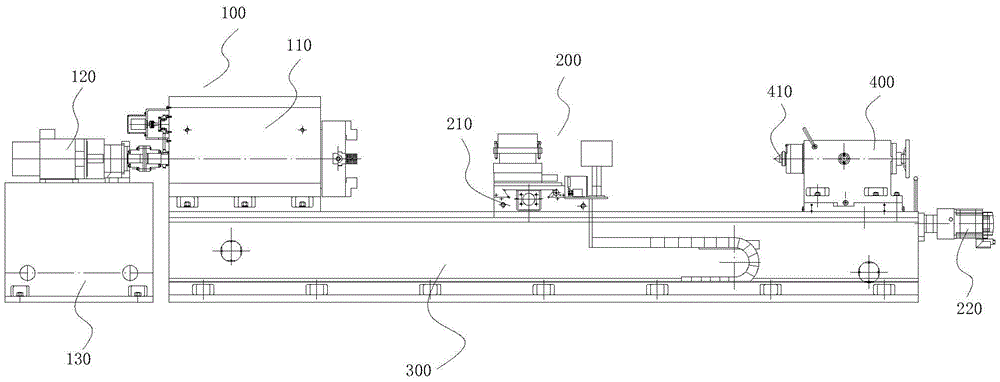

[0015] see figure 1 , a grating roller surface circumferential marking machine, comprising a headstock 100 for circumferential marking, a workbench 200 for clamping workpieces and a bed for installing the headstock 100 and the workbench 200 Body 300.

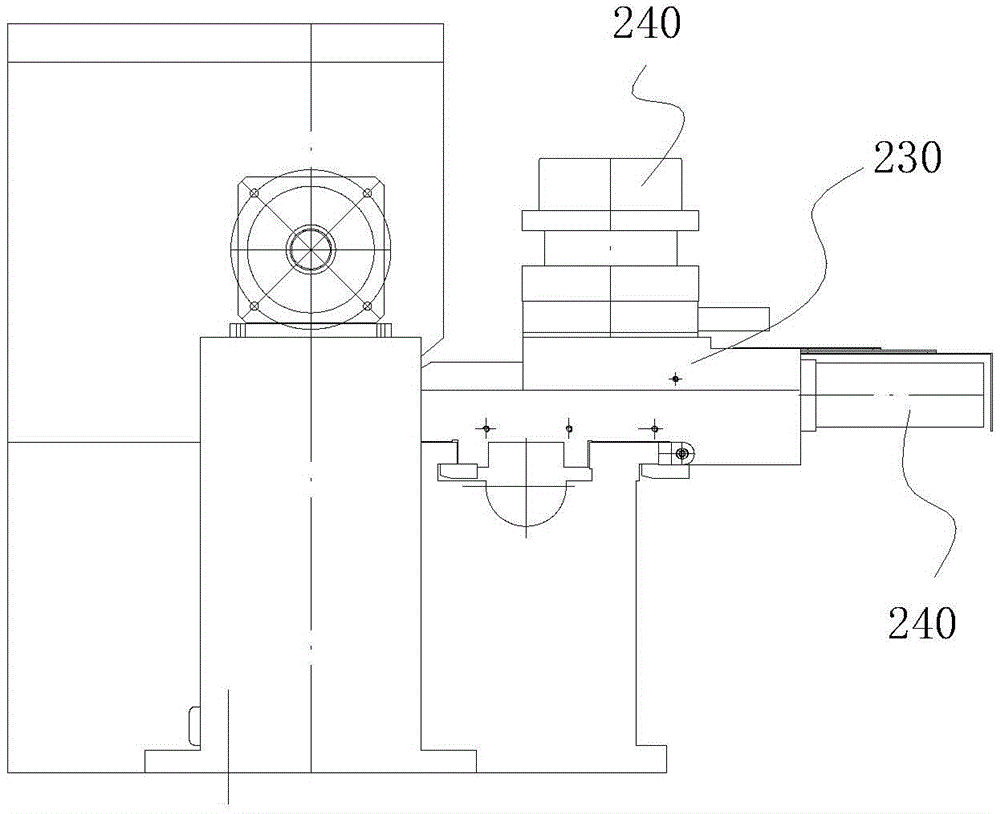

[0016] The workbench 200 includes a large carriage 210. The bed 300 is provided with an X-axis track for the workbench 300 to move along the X-axis and a large carriage transmission assembly 220. The large carriage 210 is arranged on the X-axis track and passes through the large carriage. The transmission assembly 220 drives the large carriage to move along the X-axis track; the large carriage 210 is provided with a cross slide 230, and the large carriage 210 is also provided with a Y-axis track for the cross slide 230 to move along the Y axis and a cross slide drive assembly 240 , the cross slide 230 is arranged on the Y-axis track and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com