Deviation correcting compound tool for machining camshaft hole of diesel engine body

A technology of camshaft hole and compound tool, which is applied in the field of deviation correcting compound tool, can solve the problem of large machining error, achieve the effects of reducing hole diameter deviation, avoiding damage, and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

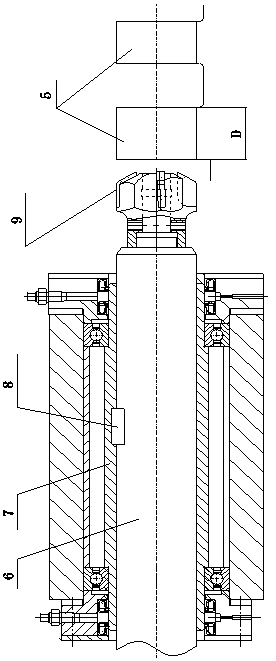

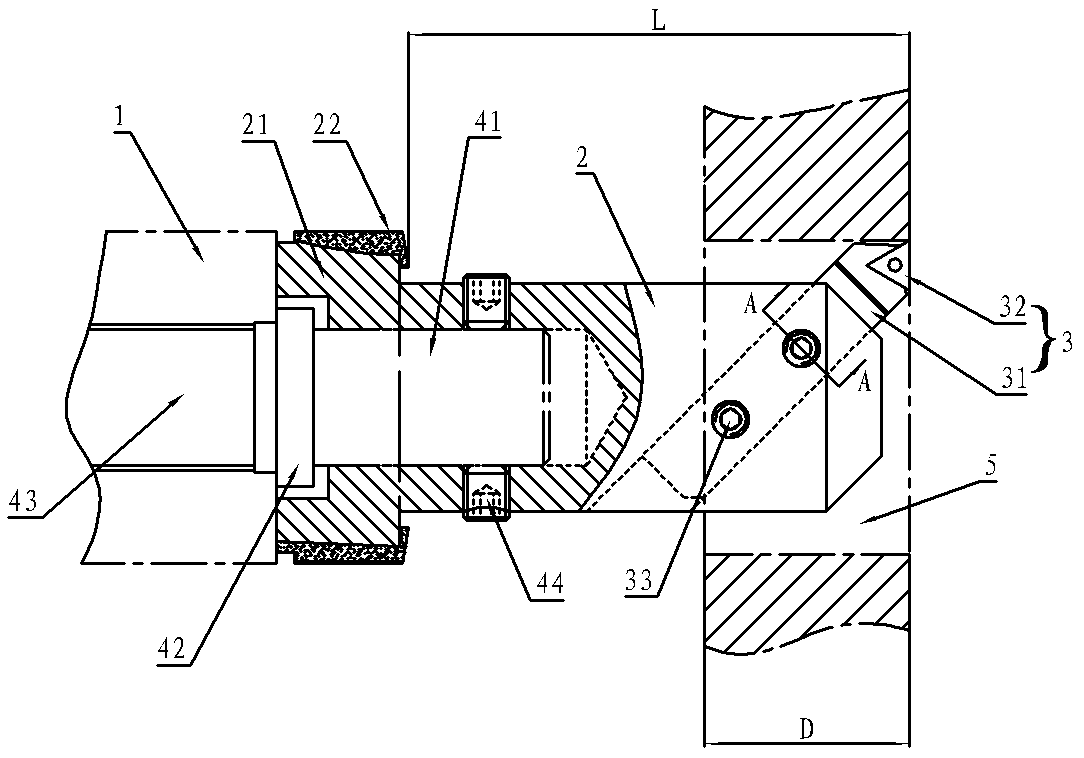

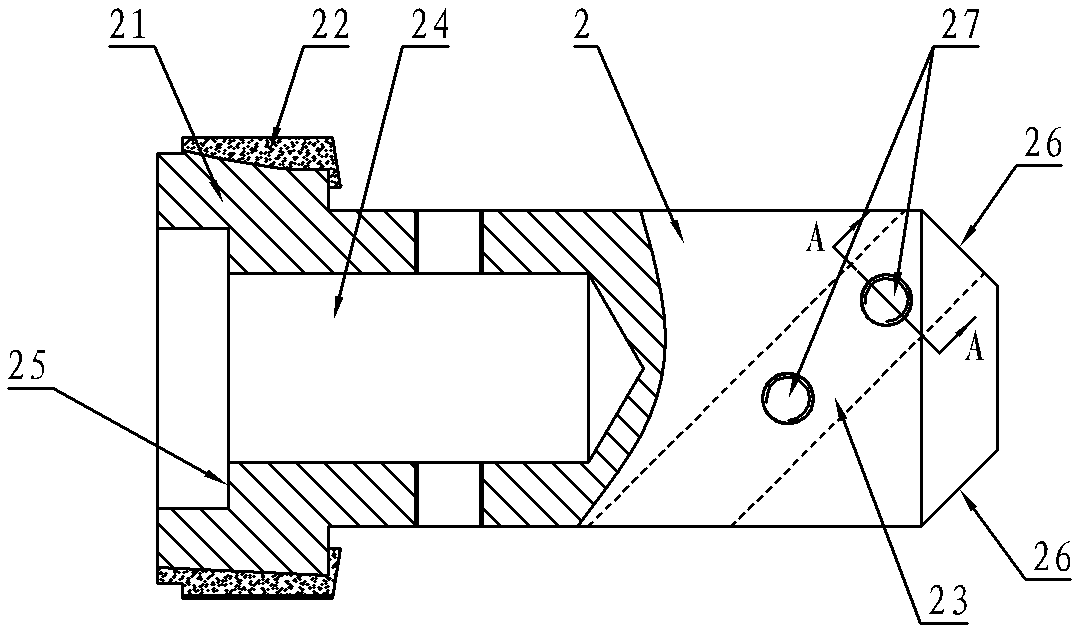

[0019] The so-called front end in this embodiment refers to the end close to the camshaft hole, and the so-called rear end refers to the side end away from the camshaft hole. See figure 2 , the present invention is used for the camshaft hole machining of diesel engine body, which comprises a tool rod 1 and a reamer 2, the reamer 2 is concentrically mounted on the cutter rod 1, and the front end of the reamer 2 is adjustable Boring cutter 3, the rear end of reaming cutter 2 is provided with reaming cutter head 21, and the circumferential surface of reaming cutter head 21 is uniformly welded with six cutting blades 22 (see Figure 4 ), which is responsible for large margin cutting, the leading angle of the boring tool 3 is 90°, the leading angle of the reaming tool 2 is 80°-85°, the front end face of the cutting blade 22 on the head of the reaming cutter is in contact with the boring tool 3 The distance L between the knife faces is greater than the width D of the camshaft hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com