Vibration grinding method and device

A grinding method and technology of a grinding device, which are applied to grinding machines, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc., which can solve the problems of inconvenient discharging of parts, complex structure of grinding machines, and unfavorable large-scale production, etc. problems, to achieve the effect of convenient discharge, diversified functions and uses, and conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

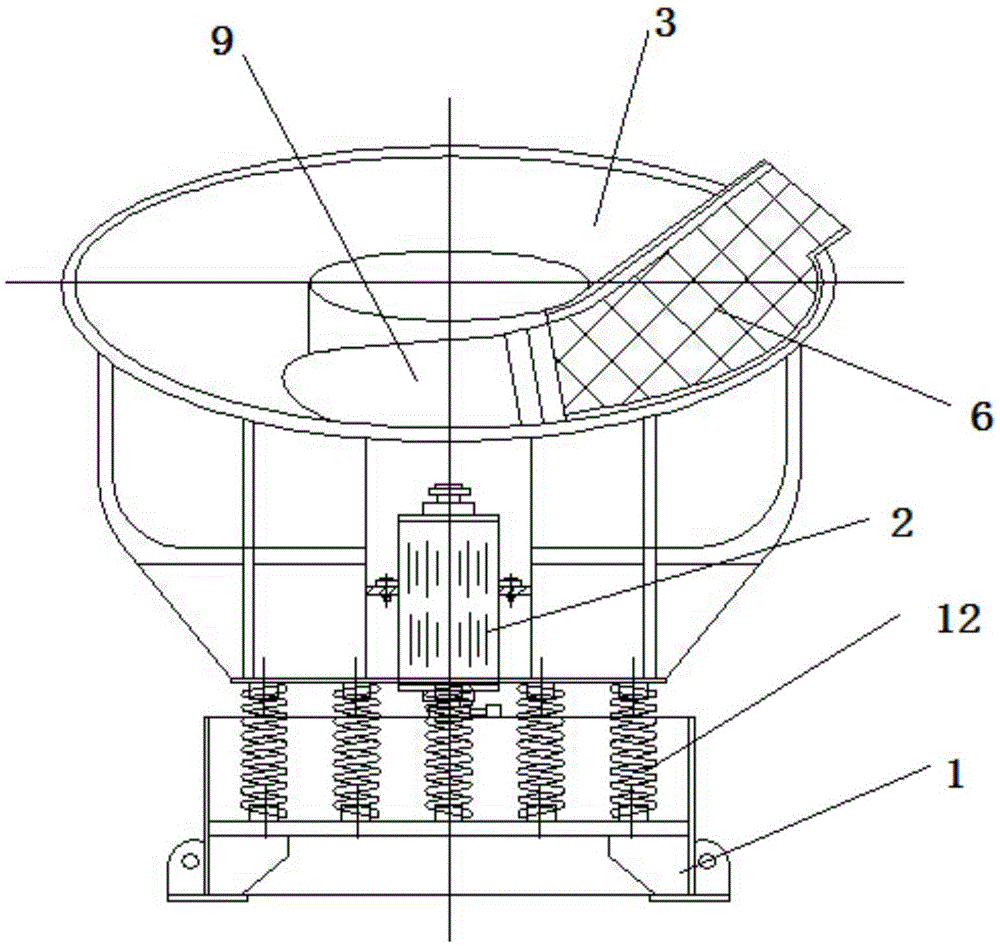

[0022] Example 1. The structure of the single groove vibration grinding machine is as follows: figure 1 As shown, including a base 1, a vibrating motor 2 is provided above the base 1, an annular grinding tank 3 with a flat groove structure is provided above the vibrating motor 2, a first screen plate 6 is provided at the outlet of the grinding tank 3, and the first screen plate 6 is connected with a first discharge plate 9; the first discharge plate 9 is a swing structure, and one end of the first discharge plate 9 is in contact with the bottom of the grinding tank 3, and the other end is connected with the first screen plate 6. Its working principle: Grind and discharge the parts through the vibration motor 2, the annular grinding tank 3 and the first discharge plate 9 that can swing up and down at one end; put the parts to be ground into the grinding tank 3 loaded with abrasives, and control The rotation direction of the vibrating motor 2 is the same as that of the disch...

Embodiment 2

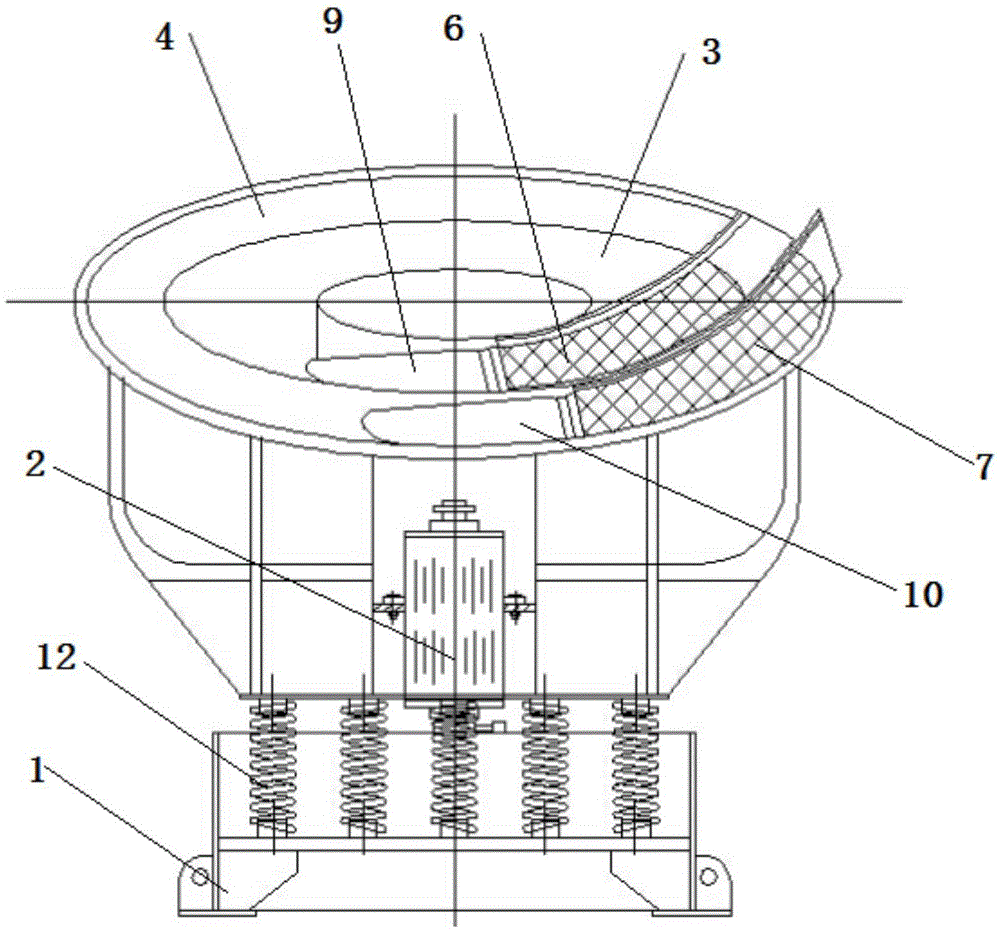

[0023] Example 2. Double groove vibrating grinder, constituted as figure 2 As shown, an annular cleaning tank 4 with a flat groove structure is provided on the outer ring of the grinding tank 3 of the single-trough vibration grinder, and a second screen plate 7 is provided at the outlet of the cleaning tank 4, and the second screen plate 7 is connected with a second The discharge plate 10 and the second discharge plate 10 are of swing structure, and one end of the second discharge plate 10 is in contact with the bottom of the cleaning tank 4 , and the other end is connected with the second screen plate 7 . Its working principle: after the parts come out of the grinding tank 3 in embodiment 1, they enter the cleaning tank 4, and the rotation direction of the vibration motor 2 is controlled to be the same as that of the discharge port. The parts and cleaning liquid flow from the bottom of the second discharge plate 10, forcing the first The second discharge plate 10 swings u...

Embodiment 3

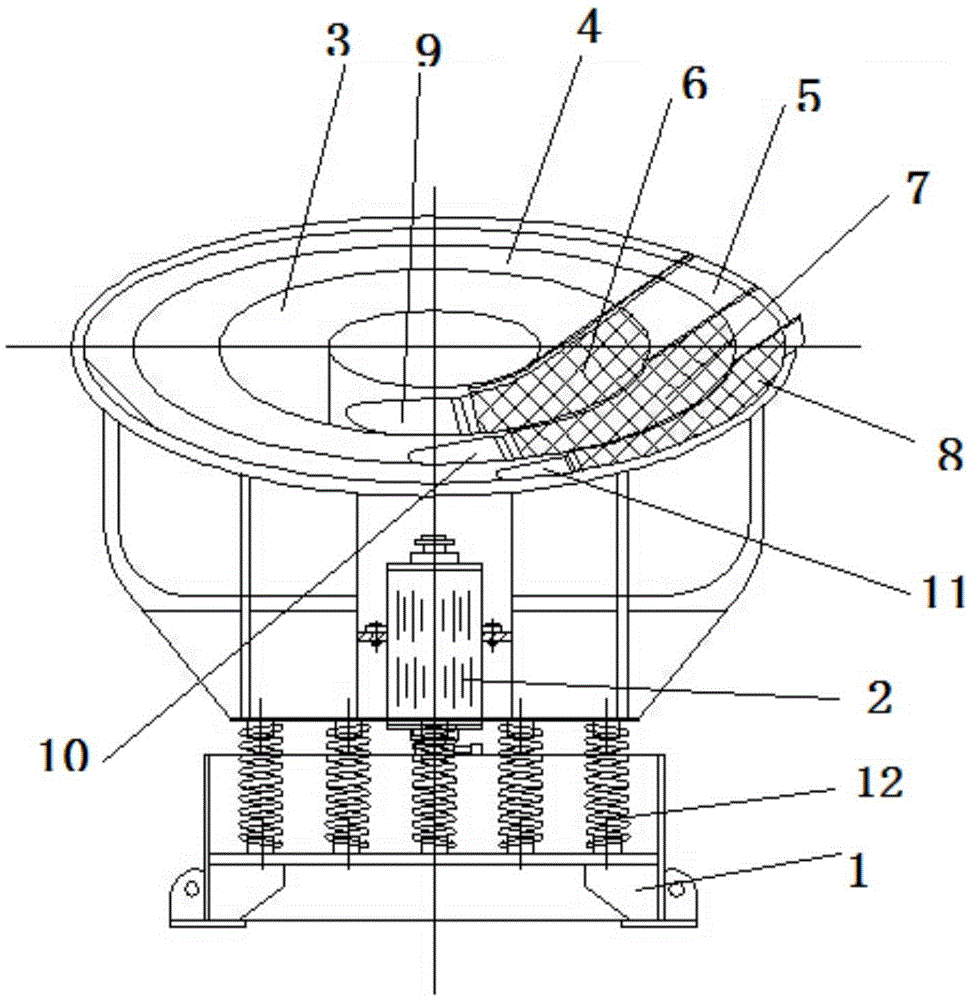

[0024] Example 3. Three-slot vibration grinder, constituted as image 3 As shown, the outer ring of the cleaning tank 4 of the double-groove vibration grinder is provided with an annular anti-rust sinking tank 5 with a flat tank structure, and a third screen plate 8 is arranged above the anti-rust sinking tank 5, and the third screen plate 8 is connected with a third discharge plate 11, the third discharge plate 11 is a swing structure, and one end of the third discharge plate 11 is in contact with the bottom of the anti-rust sinking tank 5, and the other end is connected with the third screen plate 8. Its working principle: After being cleaned by the cleaning tank 4 in embodiment 2, the parts enter the anti-rust sinking tank 5 provided on the outer ring of the cleaning tank 4, and the cleaned parts enter the anti-rust sinking tank to control the rotation direction of the vibration motor In the same direction as the discharge port, the parts flow from the bottom of the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com