Discharging small tail length cutting control method for printing equipment

A technology of printing equipment and control method, which is applied to printing, printing machines, rotary printing machines, etc., can solve the problems of large influence, large overprint deviation, and influence on overprinting accuracy, so as to reduce the loss of printing waste and realize the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

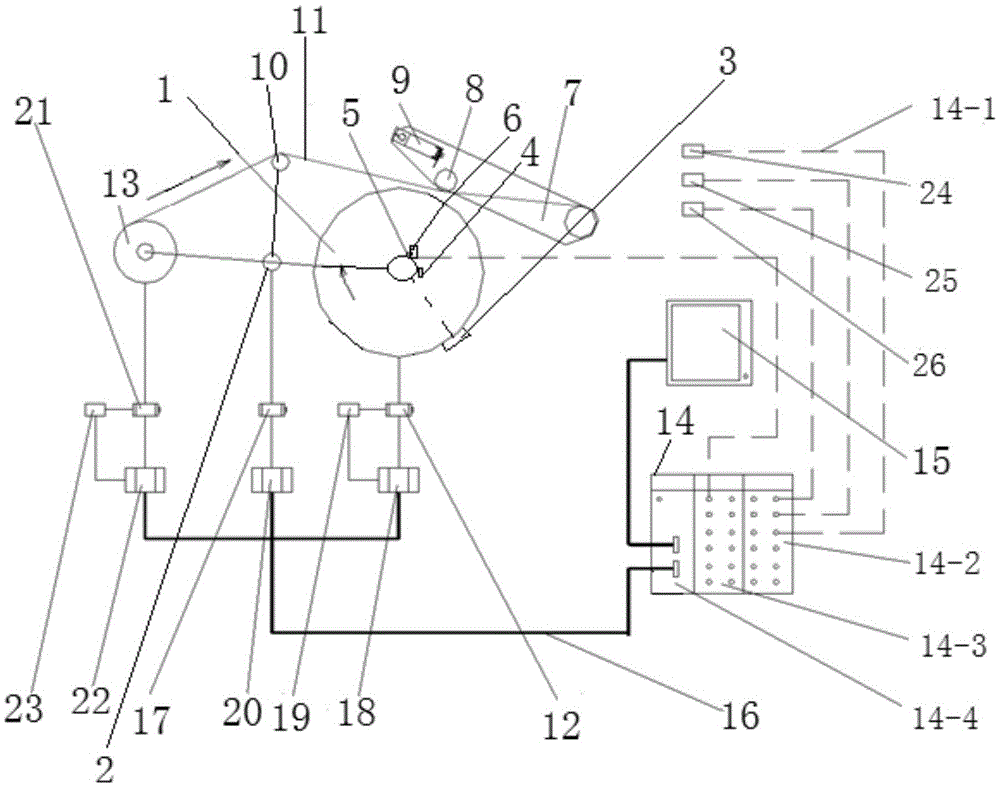

Method used

Image

Examples

Embodiment 1

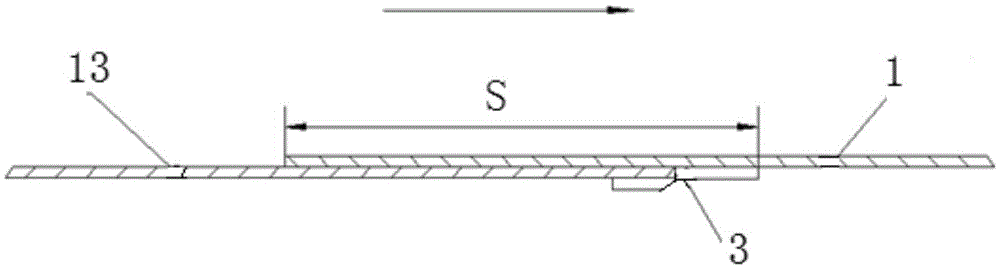

[0079] On the man-machine interface 15, the time t used by the cutting and pressing rollers from receiving the signal to pressing to receiving the new roll is respectively set. 1 =0.16, unit s; the time t used by the cutting knife from receiving the signal to cutting the material 2 = 0.08, unit s; the circumference of the new roll of receiving material C = 1055, unit mm; during cutting, the length L of the cutting pressure roller before the cutting tape is L = 300, unit mm; during cutting, the length of the tail of the cutting material Length S=200, unit mm;

[0080] The printing equipment runs at the highest line speed V max =300, m / min; set the equipment to accelerate from zero speed to the highest line speed time T=60, unit s.

[0081] The acceleration time of the preset printing equipment is t=50, the unit is s, and the line speed is calculated by formula (1)

[0082] V=(50×300) / 60=250, unit m / min.

[0083] During the cutting process, calculate C-L=1055-300=755, unit m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com