Gearboxes for low-floor rail vehicles

A technology for rail vehicles and gearboxes, which is applied in the field of gearboxes for low-floor rail vehicles, can solve the problems of many rubber coupling parts, complex structures, and complex assembly processes, and achieves small space size, simple and reliable structure, and improved performance. The effect of transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

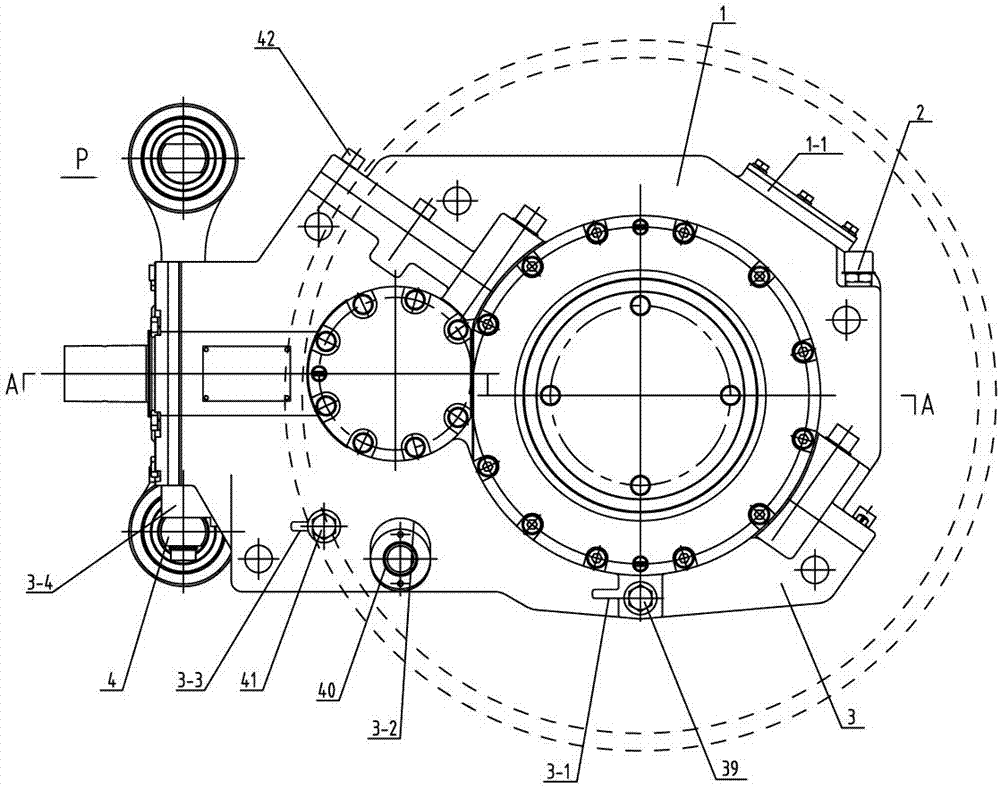

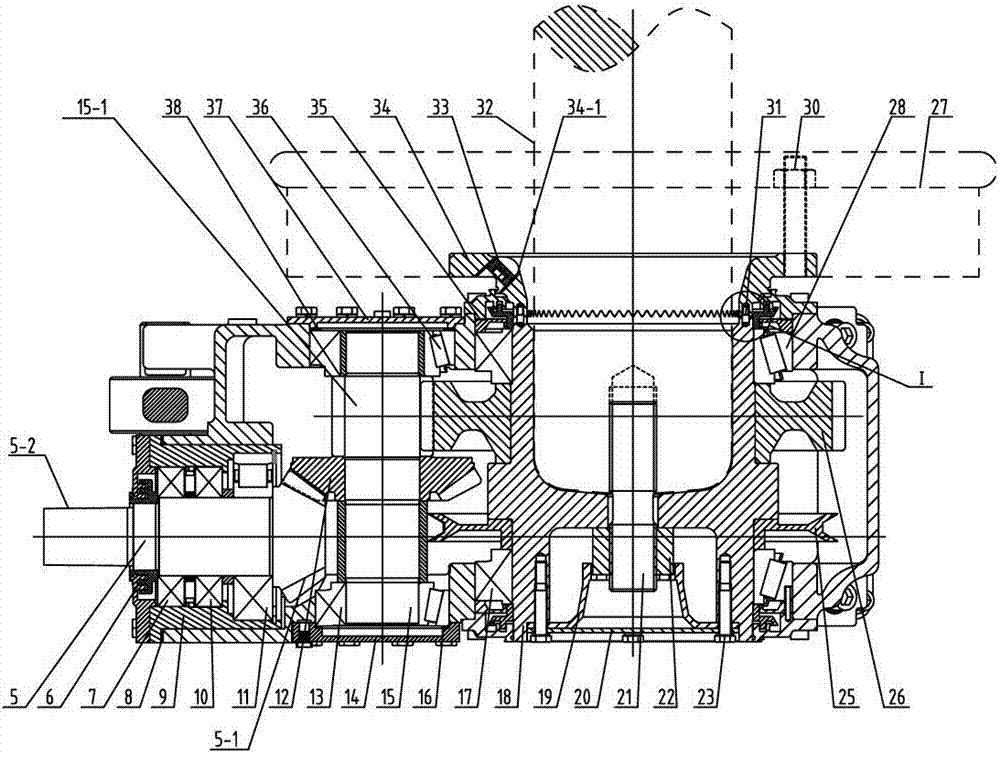

[0033] See Figure 1 to Figure 4 As shown, a gear box for a low-floor rail vehicle is characterized in that: it includes an upper box body 1 and a lower box body 3 split axially along the output shaft 18, and the upper box body 1 and the lower box body 3 are combined The box bolts 42 are fixedly connected; the upper box body 1 is provided with a breather 2 with a compact structure and an observation window boss 1-1 adjacent thereto.

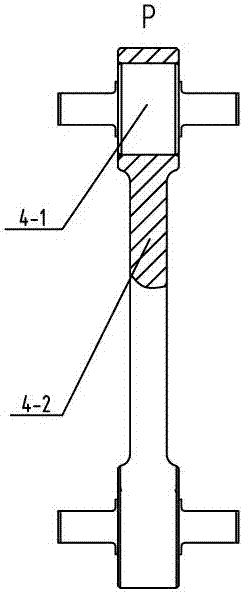

[0034] An input bearing seat 9 is installed on the lower box body 3, and an input shaft 5 is supported on the input bearing seat 9 through the first cylindrical roller bearing 7 and the second cylindrical roller bearing 11, and its axial direction passes through four points. The angular contact ball bearing 10 is limited, the four-point angular contact ball bearing 10 is arranged in the middle of the cylindrical roller bearings 7, 11, the input end of the input shaft 5 is provided with a 1:50 connecting taper surface 5-2, and the output end An a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com