A tool for automatic cable ties in narrow spaces

A small space, automatic technology, applied in the direction of bundling materials, paper/cardboard containers, containers, etc., can solve the problems such as the inability to realize automation of lagging and cable ties, and the inability to realize motor coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

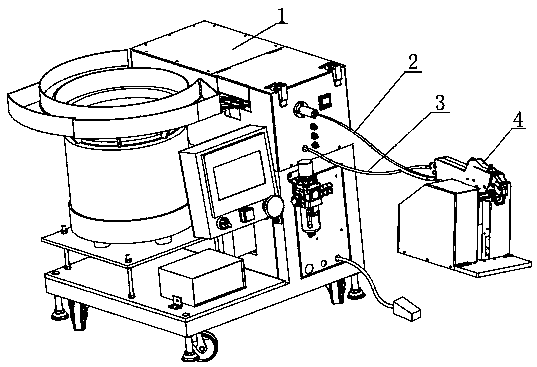

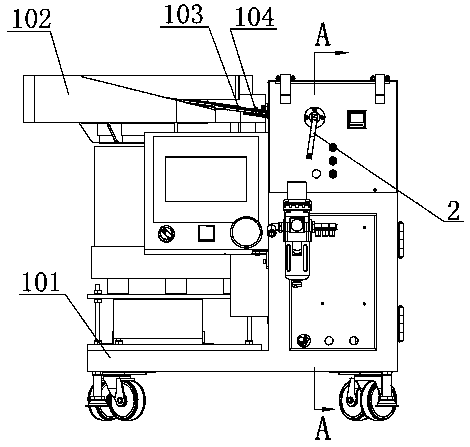

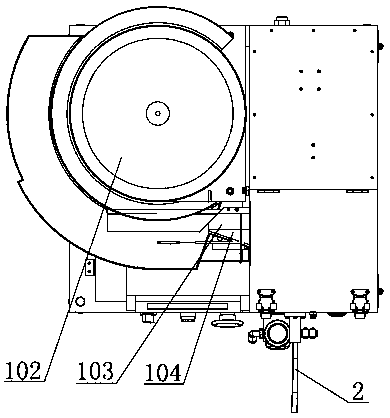

[0059] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , oneA method and tool for automatic cable ties in a narrow space, including a host 1, a feeding tube 2, a data line 3, and an automatic cable tie working head 4, the host 1 communicates with the automatic cable tie through the feeding tube 2 and the data line 3 Connected with working head 4, the host 1 includes: host frame 101, vibrating plate 102, direct vibrator 103, direct vibrating plate 104, pusher cylinder 105, pusher block 106, cable tie sensor 107, pusher body 108, the feeding pipe connector 109, the valve 110, the valve cylinder 111, the electrical control system 112 and the air valve 113 are installed on the main frame 101, the direct vibrating plate 104 is fixed above the direct vibrating device 103, and the There is a groove on the straight vibrating plate 104 for the movement and guidance of the head of the cable tie. One end of the straight vibrating plate 104 ...

Embodiment 2

[0061] Such as Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the automatic cable tie working head 4 includes an automatic cable tie working head body 41, a piercing and cutting combination module 42, a fixed second guide claw 42156, a movable second guide claw 42157, a movable second guide claw Claw cylinder 43, lifting cylinder 44, lifting cylinder 45, lifting slider 46, the fixed second guide claw 42156, movable second guide claw cylinder 43, lifting cylinder 45 are fixed on the automatic cable tie working head body 41, the movable second guide claw 42157 is connected with the action rod of the movable second guide claw cylinder 43 and can slide in the guide groove of the automatic cable tie working head body 41, the lifting Cylinder 45 is fixed on the working head body 41 of the automatic cable tie, and the lifting cylinder 44 is fixed on the lifting slider 46. The piercing, drawing and cutting combination module 42 is connected, ...

Embodiment 3

[0080] Such as Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the lifting cylinder 45 and the lifting cylinder 44 are all at the top dead center position, and the piercing, drawing and cutting combination module 42 is at the highest position and raising its head. Figure 22 Put the stator of the motor shown in the automatic cable tie working head 4, and insert the fixed second guide claw 42156 into the gap between the silicon steel sheet and the coil, step on the foot switch, and the head-raising cylinder 44 will work to the bottom dead point, The piercing, pulling and cutting combination module 42 swings downward, the frame 42150, the fixed first guide claw 4212, the movable first guide claw 4213, the fixed second guide claw 42156, the movable second guide claw The guide grooves of 42157 are docked to form a pear-shaped closed circle of guide grooves. Under the push of compressed air, the cable tie passes through the feeding pipe 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com