A mobile solid hazardous chemical filling device

A filling device, a technology for hazardous chemicals, applied in the directions of packaging, loading/unloading, transportation and packaging, to achieve the effect of convenient and rapid movement, reduced injury, and reduced hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

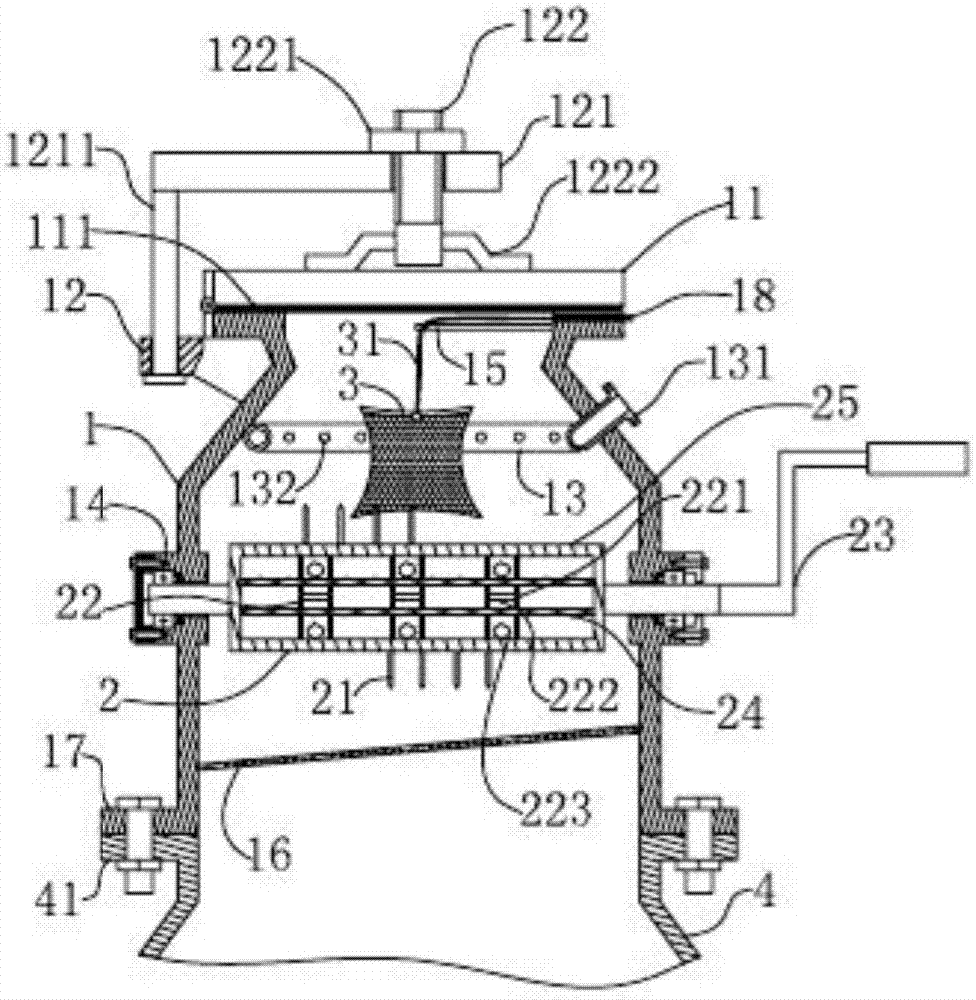

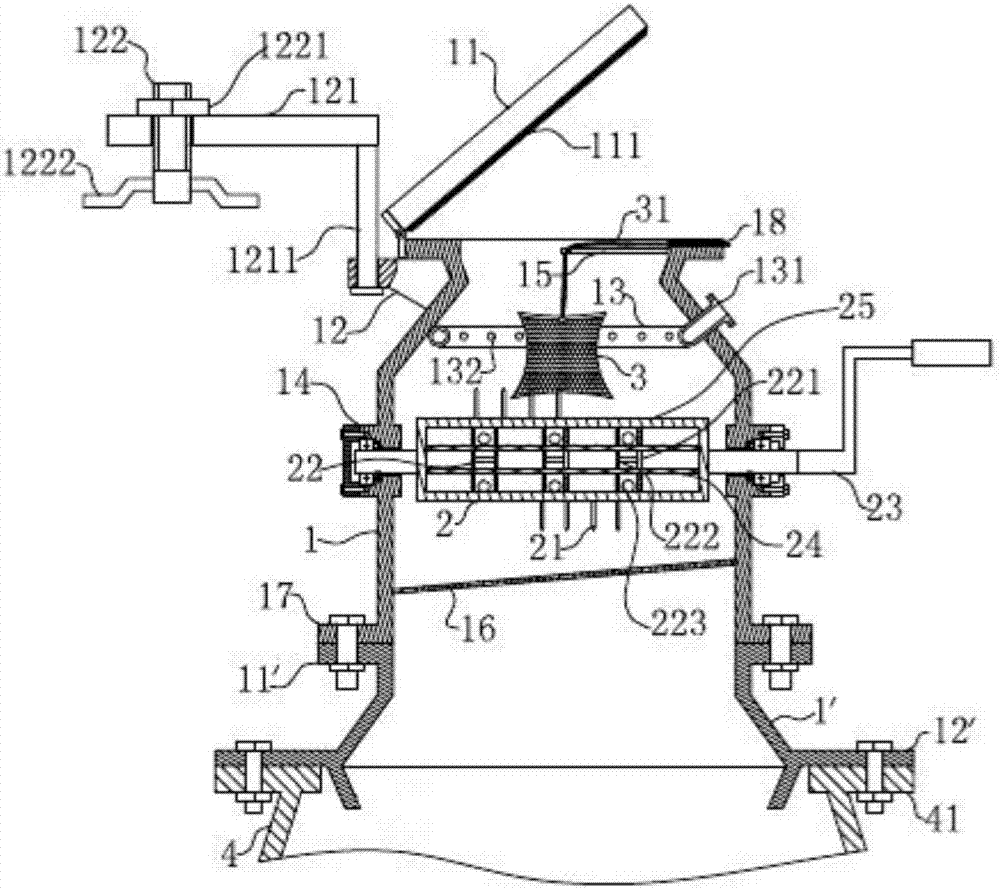

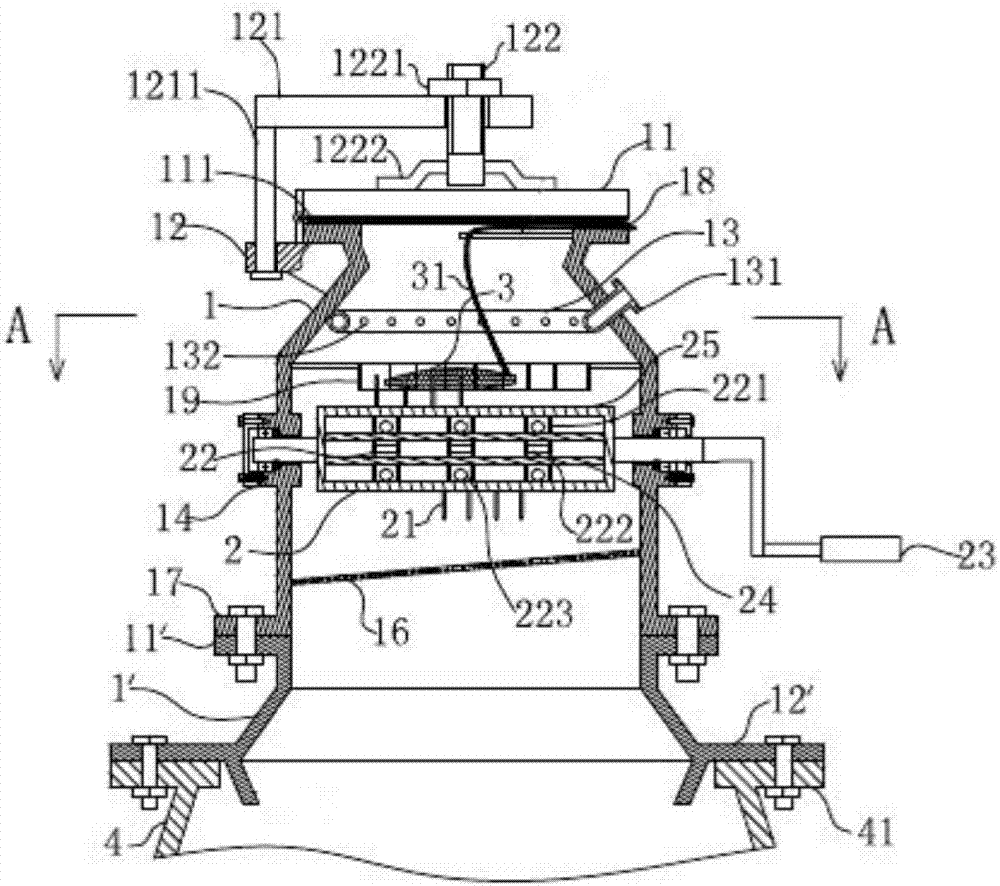

[0033] Such as Figure 1 to Figure 5 As shown, the present invention provides a mobile solid hazardous chemical filling device, which is characterized in that it includes a first tank body 1, and a branch-shaped distribution pipe 13, a rotating hub 2 and a Sieve plate 16.

[0034] The opening of the first tank body 1 is provided with an openable sealing cover 11. The branch-shaped distribution pipe 13 is mainly used to add liquid formulations to the storage tank. The outer surface of the rotating hub 2 is provided with uniformly distributed blades 21. The blade 21 traverses the first tank body 1 and drives the blade 21 to rotate with the rotating hub 2 through the outer crank handle 23 . In the specific filling process, the packaging bag 3 containing solid hazardous chemicals is put into the first tank body 1 through the traction rope 31, then the sealing cover 11 is closed, and the rotating hub 2 is driven to cut the packaging bag 3 with a blade 21. break, so that the solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com