A special non-woven fabric for ultra-soft skin mask and its manufacturing method

A technology of non-woven fabric and manufacturing method, applied in the field of non-woven fabric, can solve the problems of reduced skin-adhering property of mask base fabric, low surface density of mask base fabric, etc., and achieves low density, good resistance to environmental stress cracking, and good toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

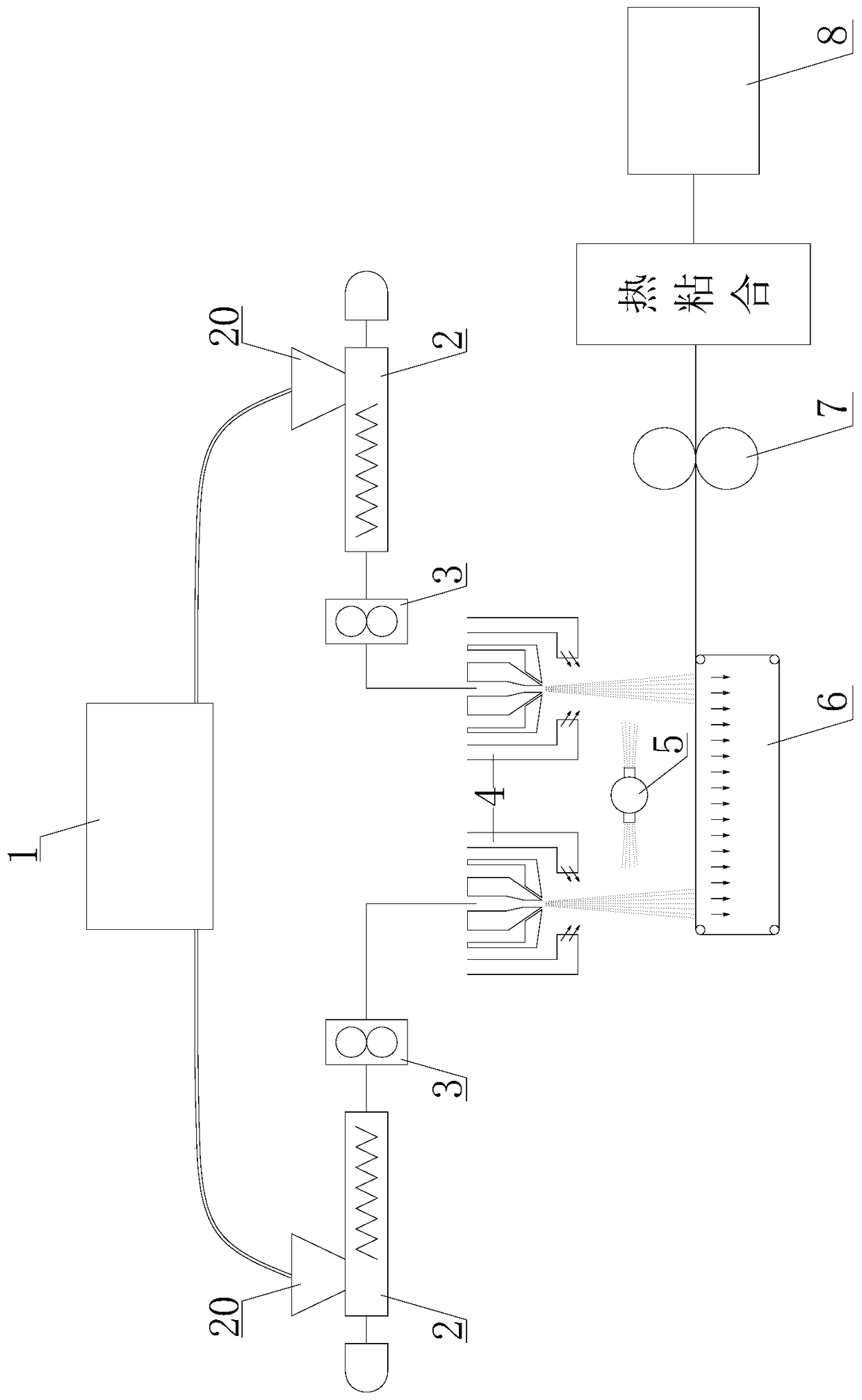

Image

Examples

Embodiment 1

[0029] Embodiment 1. It includes the following components and the mass ratio of each component is: propylene-based elastomer: 35 parts, polypropylene resin: 12 parts, hydrophilic masterbatch: 2.5 parts, soft masterbatch: 0.5 part.

Embodiment 2

[0030] Embodiment 2 includes the following components and the mass ratio of each component is: propylene-based elastomer: 70 parts, polypropylene resin: 24 parts, hydrophilic masterbatch: 5 parts, soft masterbatch: 1 part.

Embodiment 3

[0031] Embodiment 3, including the following components and the mass ratio of each component: propylene-based elastomer: 105 parts, polypropylene resin: 36 parts, hydrophilic masterbatch: 7.5 parts, soft masterbatch: 1.5 parts.

[0032] Embodiment one to embodiment three are made a kind of special non-woven fabric of super soft sticking mask: the steps are as follows:

[0033] a) Embodiment Configure raw materials according to the mass ratio of each component.

[0034] b) Mixing and stirring of raw materials: put the configured raw materials in the static mixer 1 and stir evenly for pre-melting treatment. The temperature of the static mixer 1 is set at 20-45° C., and the stirring time is 10-15 minutes.

[0035] Wherein, the temperature of the static mixer 1 is set at 40° C., and the stirring time is 13 minutes. The raw materials are treated with low-temperature static stirring, so that the propylene-based elastomer and polypropylene resin maintain good flexibility, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com