Washing machine self-cleaning circulating filtering system and self-cleaning method

A circulating filtration and washing machine technology, applied in the field of washing machines, can solve the problems of great damage to washing machines and laundry, loss of filtering function of filter devices, accumulation of impurities in filter membranes, etc., achieve good backwashing effect, reduce the cost of replacing filter modules, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

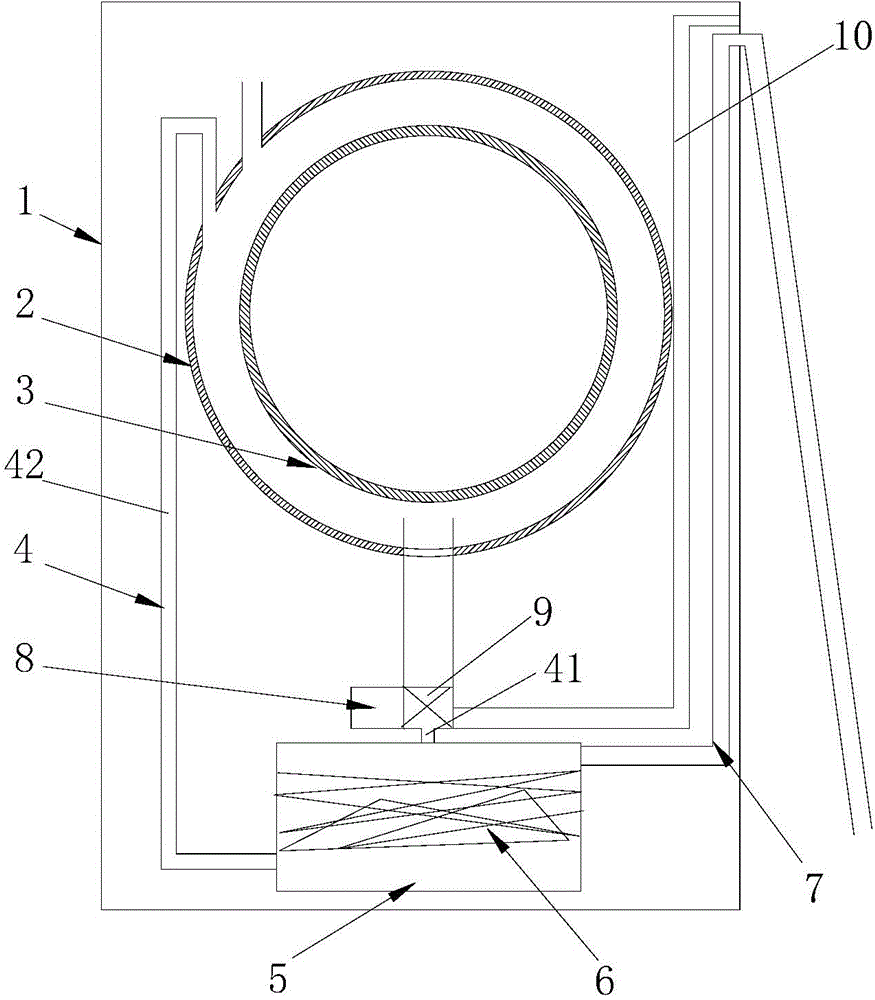

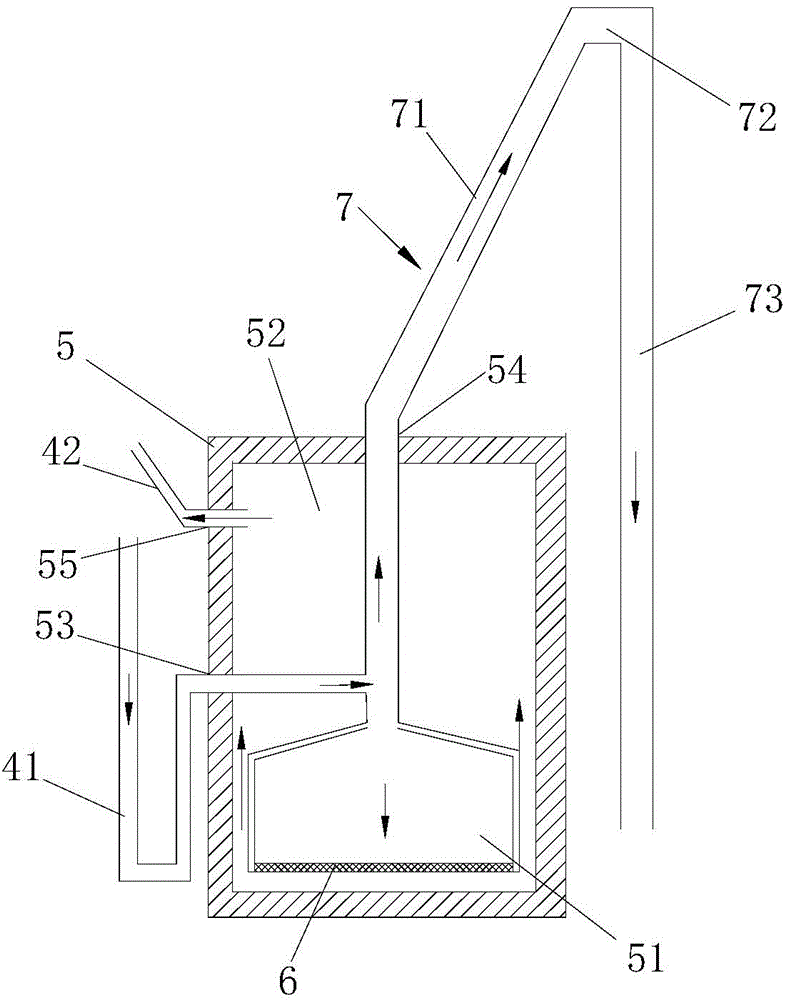

[0041] Such as figure 2 As shown, in this embodiment, the first chamber 51 is disposed inside the second chamber 52 . The inside of the water storage tank 5 is provided with an independent space, the independent space is the first chamber 51, the space outside the first chamber 51 is the second chamber 52, and the water inlet pipeline 41 and the siphon pipeline 7 pass through the second chamber respectively. The chamber 52 communicates with the first chamber 51 , and the outlet pipe 42 directly communicates with the second chamber 52 .

[0042] The filter module 6 is a filter membrane structure, the first chamber 51 communicates with the second chamber 52 only through the filter membrane structure provided at the lower part, and the upper part communicates with the siphon pipeline 7 and the water inlet pipeline 41 respectively.

[0043] The circulating pump 8 is a drainage pump located at the drain part of the washing machine tub, and the drainage pump communicates with the ...

Embodiment 2

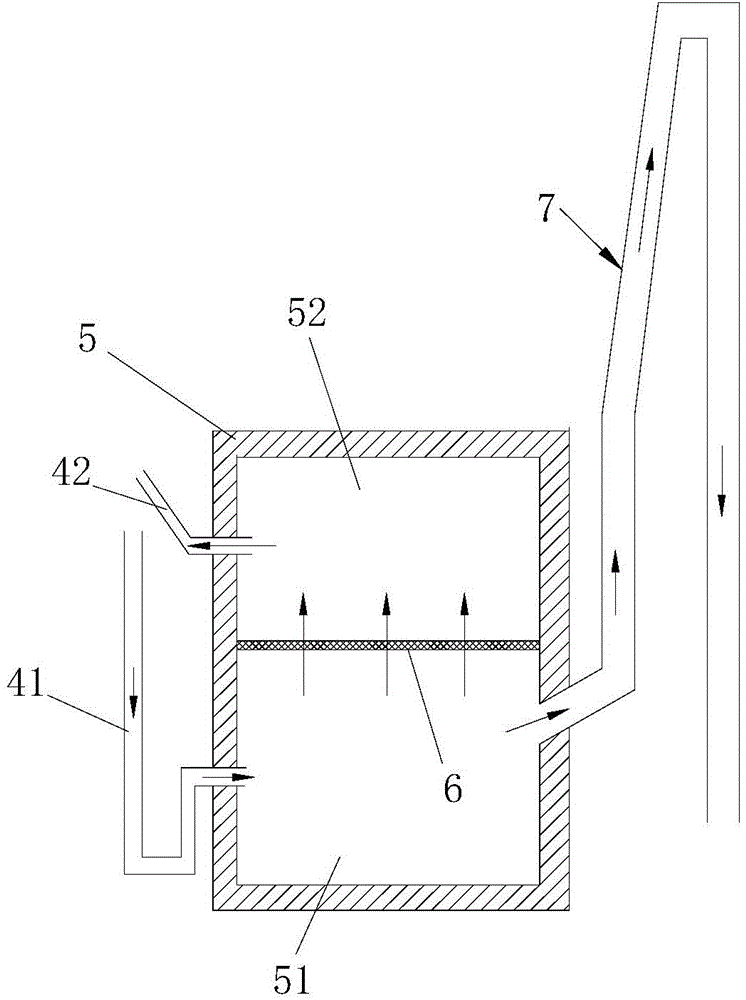

[0047] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is that the second chamber 52 and the first chamber 51 are in an up-and-down positional relationship. The filter module 6 divides the internal space of the water storage tank 5 into upper and lower parts. The upper part of the space is the second chamber 52, which communicates with the water outlet pipeline 42, and the lower part of the space is the first chamber 51, which is connected to the water inlet pipeline 41 and the siphon respectively. Road 7 connects.

[0048] The upper and lower positional relationship of the two chambers also includes that the upper space is the first chamber and the lower space is the second chamber, see figure 1 . Because the water outlet is relatively in the middle and lower part of this structure, it takes a long time to destroy the siphon, and the amount of water sucked is relatively large, so the relative backwashing effect is better.

Embodiment 3

[0050] Such as Figure 4 As shown, the first chamber 51 and the second chamber 52 in this embodiment are divided into left and right sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com