Rail waist grinding and derusting machine

A technology of derusting machine and rail waist, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of equipment movement, unguaranteed grinding quality, and high labor intensity of operators, so as to eliminate the influence of grinding wheel wear and improve grinding. Derusting efficiency and improving the effect of grinding and derusting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

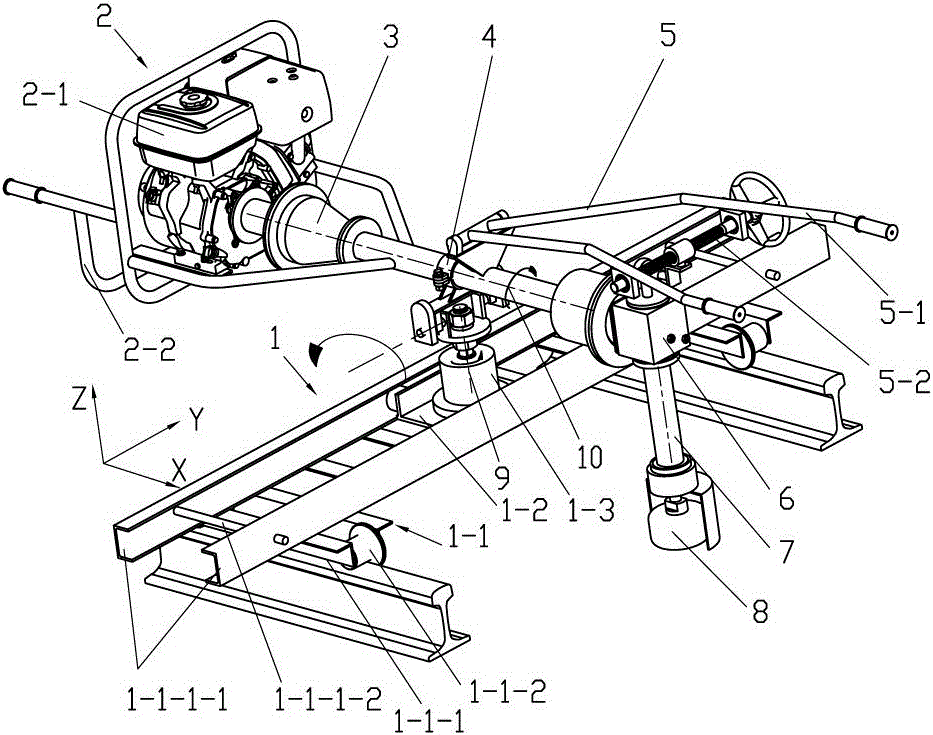

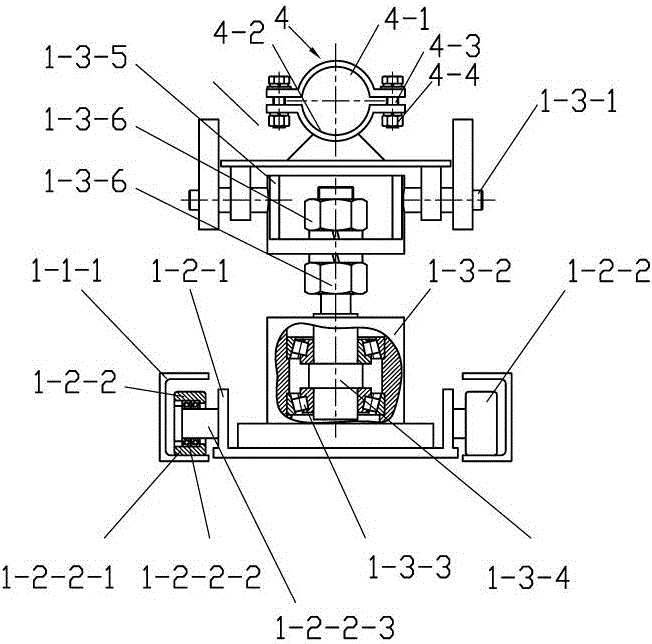

[0024] Such as Figure 1-7 As shown, a rail waist grinding and derusting machine of the present invention includes a power unit 2 and a grinding wheel 8, and also includes: an underframe trolley assembly 1, a connecting buckle 4, a power horizontal transmission assembly 3, and a gear steering box assembly 6. The power vertical transmission assembly 7 and the armrest assembly 5, the power device 2 is connected to the power horizontal transmission assembly 3, the power horizontal transmission assembly 3 is connected to the gear steering box assembly 6, and the gear steering box assembly 6 transmission connection power vertical transmission assembly 7, power vertical transmission assembly 7 transmission connection grinding wheel 8, the chassis trolley assembly 1 includes chassis trolley 1-1, mobile trolley 1-2 and supporting device 1-3 , the underframe trolley 1-1 has a guide wheel 1-1-2 that can walk along the track, the mobile trolley 1-2 is arranged on the underframe trolley 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com