Building method of plastering-free high-precision infilled wall

A filling wall and plaster-free technology, applied to walls, buildings, building components, etc., can solve the problems of wasting natural resources, labor and construction period, drumming, falling off, etc., to reduce natural mining, save construction costs, The effect of saving labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

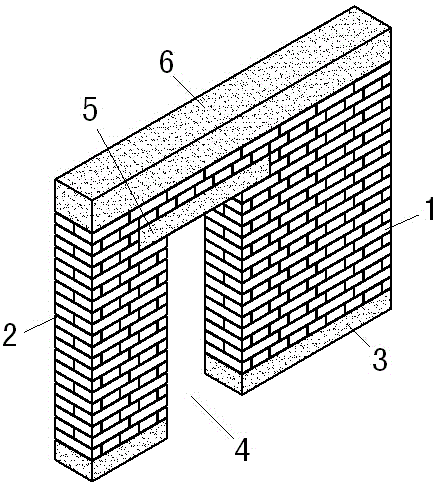

[0015] A method for building a plaster-free high-precision filling wall, the method selects a high-precision autoclaved aerated concrete block 1 with a standardized shape as a building block for the filling wall; before building the filling wall, if figure 1 Typesetting by computer as shown. During typesetting, typesetting is carried out on the computer at 1:1 according to the actual size of the wall. The bottom of the filling wall is provided with a guide wall 3 with a height of 200 mm. If the wall needs to be equipped with a door 4, the guide wall 3 should be divided into two two paragraphs. Typesetting on the computer is to build walls according to the construction requirements on the computer according to the size of the block. The typesetting is to reserve the positions of the mortar joint 2 and the door 4 according to the actual requirements. The bottom surfaces of the beams 6 are connected. The height and width of the infill wall and the amount of blocks can be acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com