Method for manufacturing luxurious fireproof anti-explosion door

A kind of explosion-proof door, luxurious technology, used in fire doors, door leaves, anti-war damage and other directions, can solve the problems of low grade, inconsistent color and texture, single style of fireproof and anti-theft doors, etc., to achieve good fire resistance and super fire resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

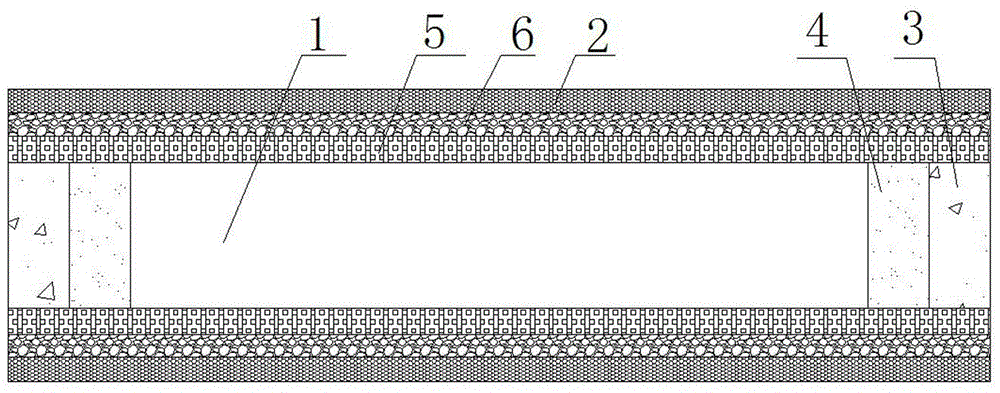

[0019] A luxurious fire-proof and explosion-proof door, including a door leaf 1, a decorative panel 2, and a door frame cover 3, characterized in that: the four sides of the door leaf 1 are outsourced with square tubes 4, and the square tubes 4 are filled with thick carbon fiber boards and high-strength PE non-woven seams. Fabric, door leaf 1 double-sided sealing metal plate 5 and flame-retardant multilayer board 6, veneer 2 is pasted on the outside of flame-retardant multilayer board 6, door frame cover 3 is outsourced on the upper and lower ends of door leaf 1, and the squares on the left and right sides of door leaf 1 Pipe 4 outer sealing flame retardant solid wood strips.

[0020] The veneer 2 is made of carbonized red oak board or carbonized wood with better texture of other tree species.

[0021] The alleged door frame cover 3 is made of electrolytic galvanized steel plate, the thickness of the steel plate is not less than 2.5mm; solid wood filling, solid wood vene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com