Electromagnetic pilot pneumatic-control two-position three-way valve

A two-position three-way valve and pilot technology, applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problems of lack of discharge function, large volume, slow response, etc., and achieve the elimination of tumbling phenomenon, small volume, and fast response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

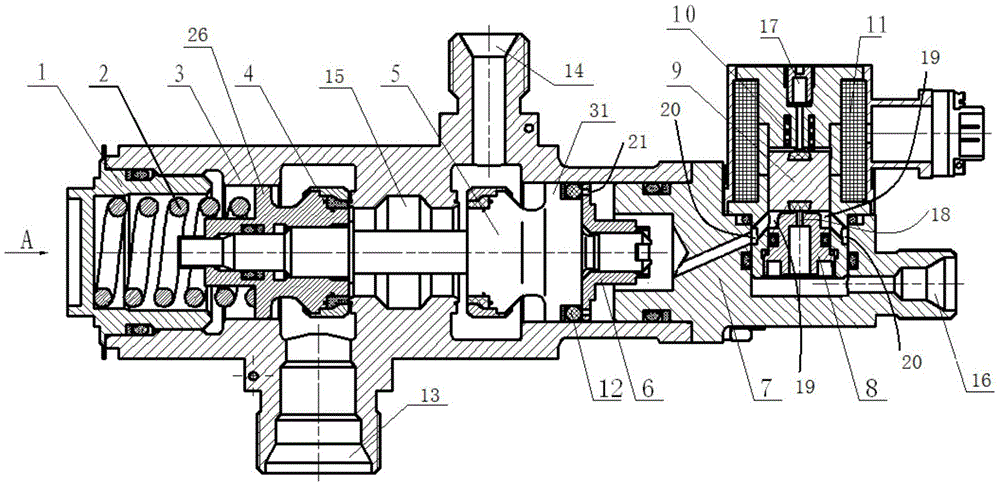

[0034] In order to realize multiple start and shutdown of the engine, reduce the mass of the engine, and improve the response speed of the engine, a new control valve with shutdown discharge function must be designed. The valve needs to have the main performance of being able to work repeatedly, with a working pressure range of 0-11MPa, a working flow range of 0-1.5kg / s, a flow resistance of less than 0.3MPa, a control air pressure of 7-12MPa, and a response time of less than 50ms.

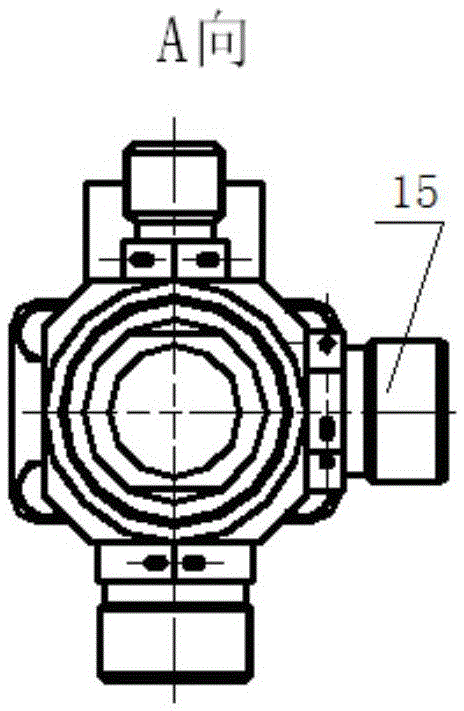

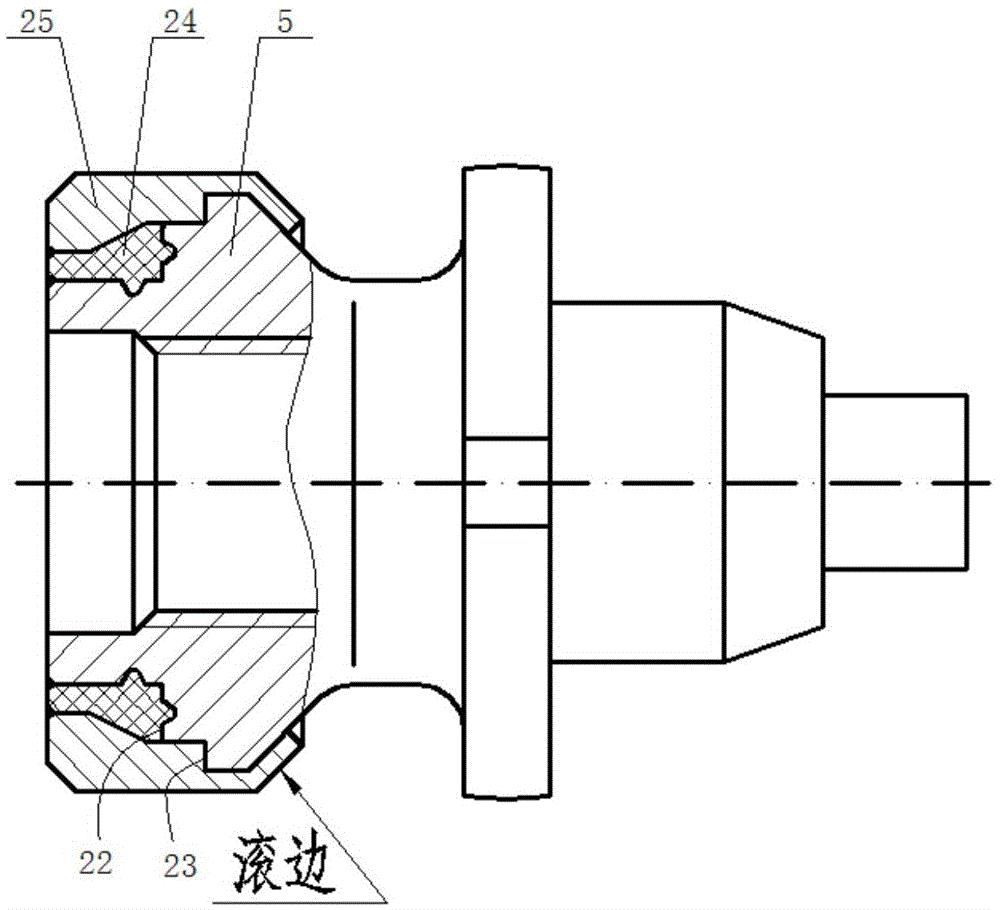

[0035] like figure 1 The electromagnetic pilot air-controlled two-position three-way valve structure shown is a preferred embodiment of the present invention. It consists of a plug 1, a main spring 2, a main valve body 3, a main valve core 4, a discharge valve core 5, a dynamic sealing ring 6, Inflator 7, auxiliary valve seat 8, auxiliary valve core 9, auxiliary valve spring 10, electromagnetic assembly 11 and sealing ring 12 etc. are composed.

[0036] The implementation example of applying the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com