Control method and system for preventing fuel-water ratio imbalance of once-through boilers in thermal power plants

A once-through boiler, fuel-water ratio technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the problem of affecting the stability of the control system, the economy of unit operation, prone to misoperation, overheating of the main steam temperature, etc. problem, to achieve the effect of preventing the imbalance of the fuel-water ratio of the once-through boiler in the thermal power plant, preventing the temperature at the middle point from being too high, and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

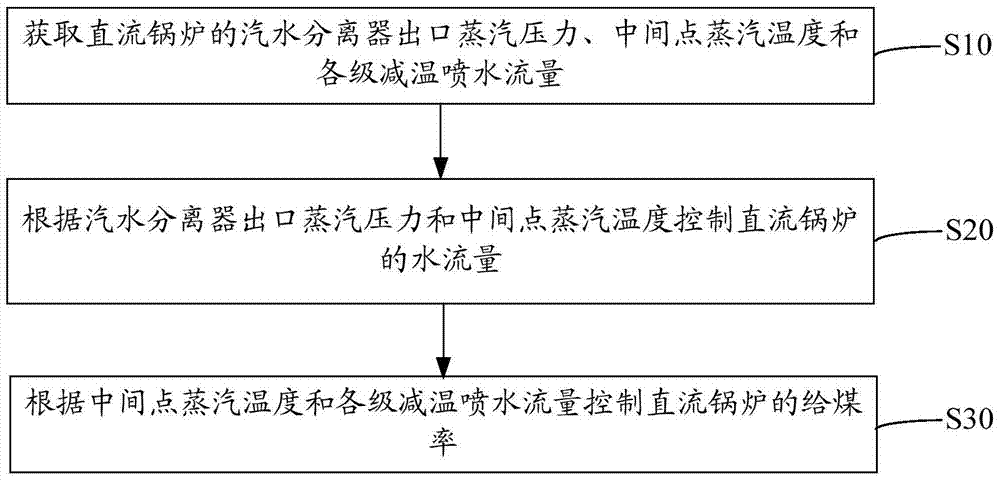

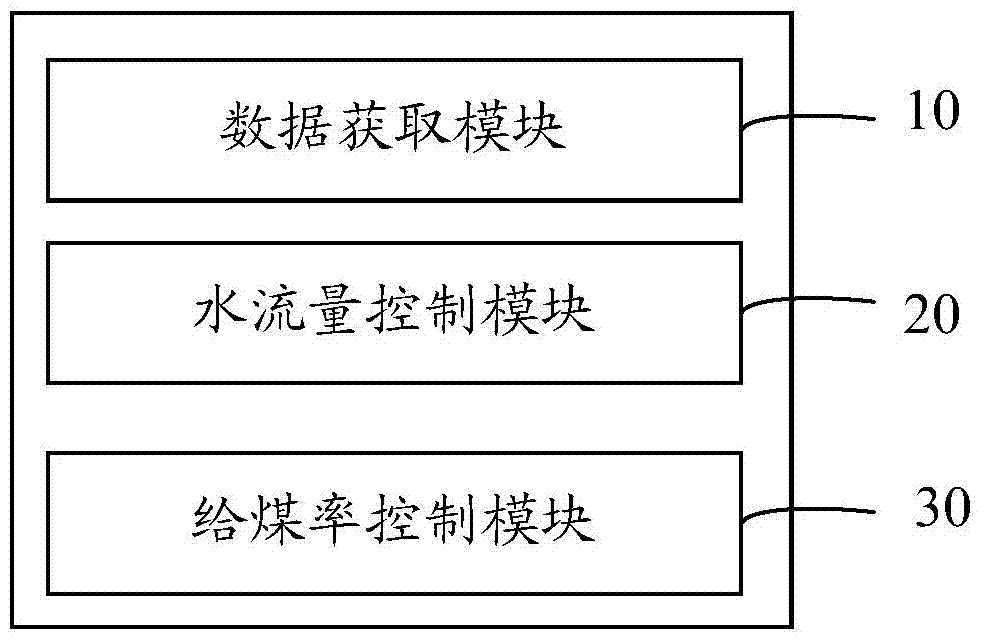

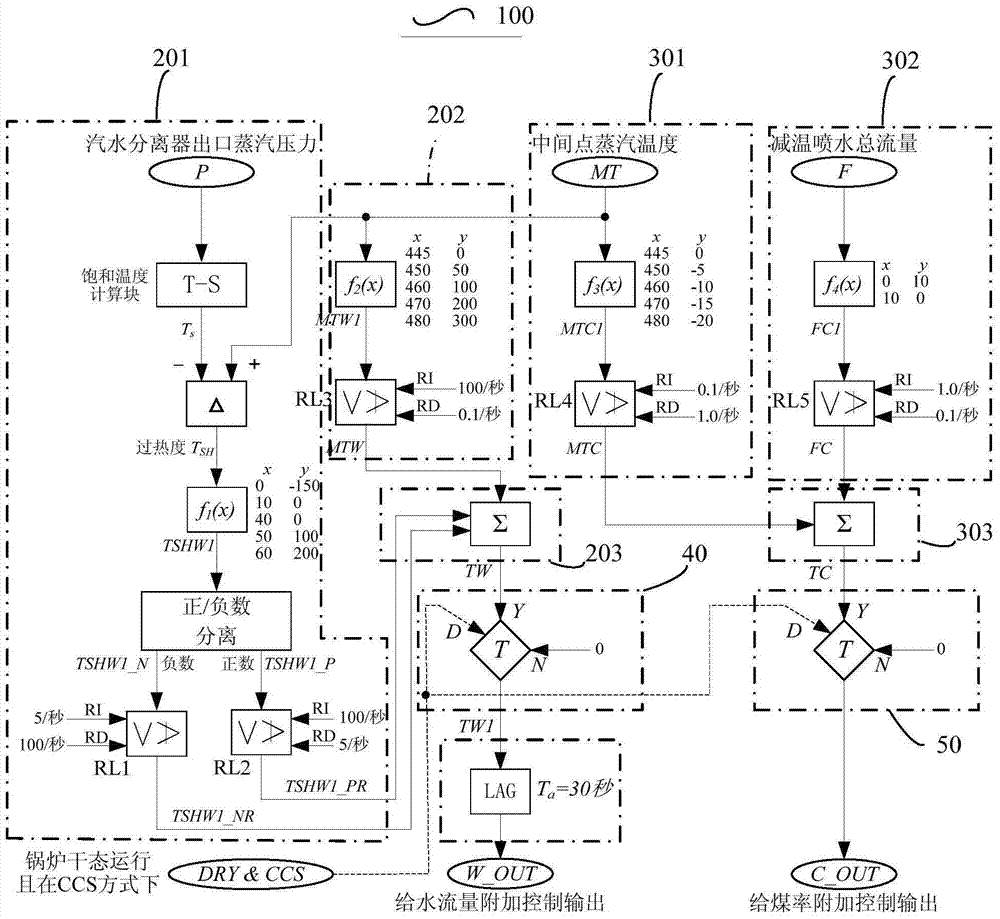

[0049] Such as figure 1 As shown, a control method for preventing the fuel-water ratio imbalance of once-through boilers in thermal power plants includes the following steps:

[0050] S10: Obtain the steam pressure at the steam-water separator outlet of the once-through boiler, the steam temperature at the intermediate point, and the desuperheating spray water flow at each level.

[0051] S20: Control the water flow of the once-through boiler according to the steam pressure at the outlet of the steam-water separator and the steam temperature at the intermediate point.

[0052] S30: Control the coal feeding rate of the once-through boiler according to the steam temperature at the intermediate point and the flow rate of water injection for desuperheating at each stage.

[0053] The control method for preventing the fuel-water ratio imbalance of the once-through boiler in the thermal power plant of the present invention controls the water flow of the once-through boiler and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com