Air energy auxiliary preheat heating method and water heating unit thereof

A hot water unit and air energy technology, applied in the heating field, can solve the problems of high energy consumption, low thermal efficiency, serious air pollution, etc., and achieve the effect of low energy consumption, high thermal efficiency, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The technical scheme of the present invention will be described in detail below by taking the electromagnetic heating unit as an example.

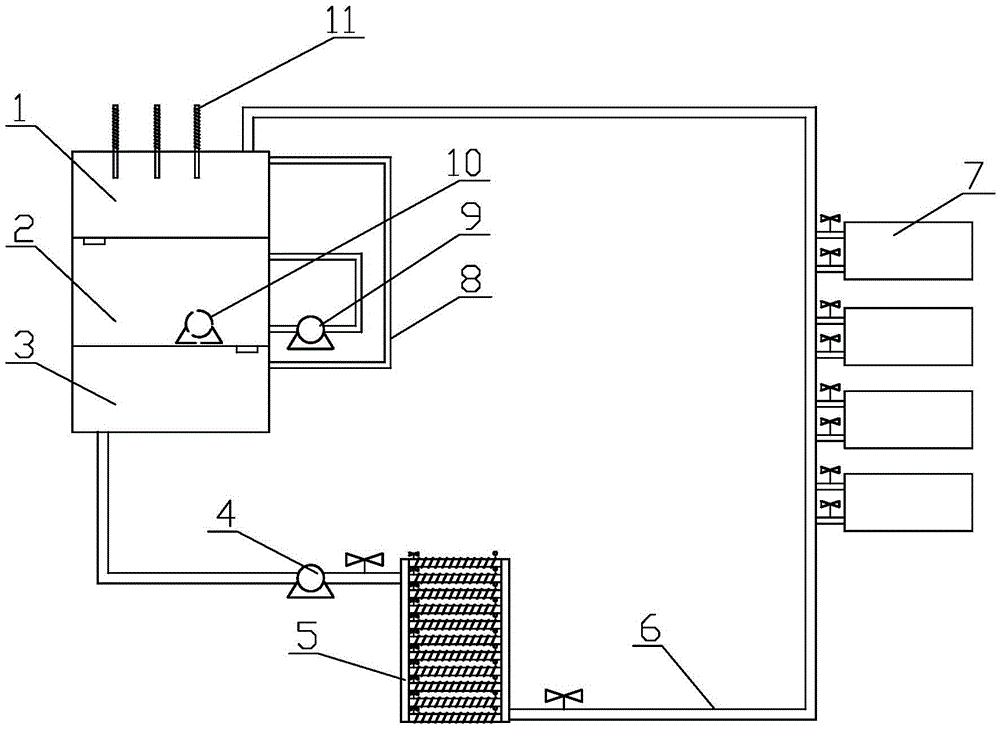

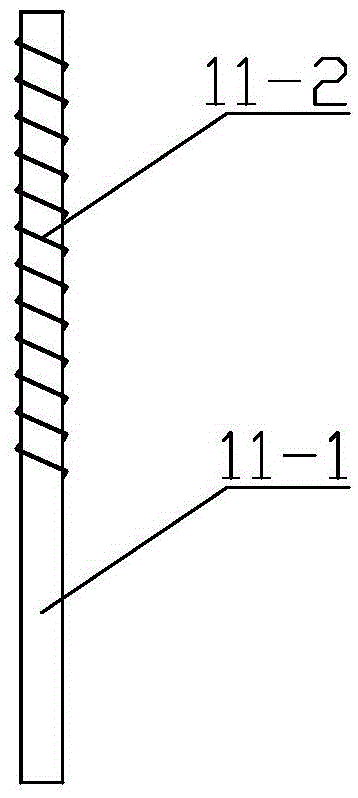

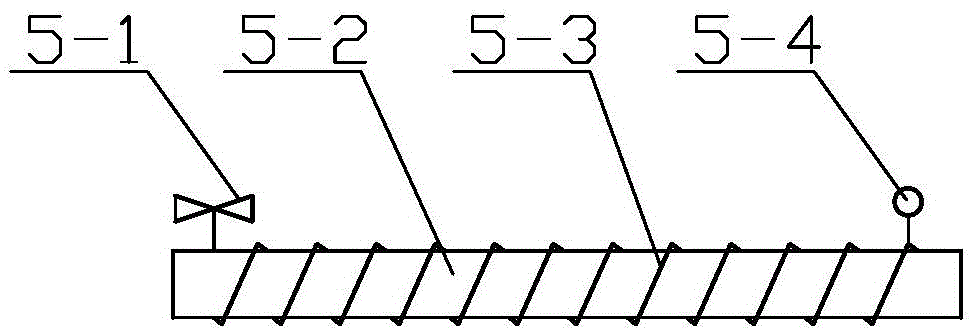

[0030] like figure 1 , figure 2 , image 3 As shown: the water tank is composed of a high water tank 1, a middle water tank 2, and a low water tank 3. The water outlet at the bottom of the high water tank 1 is connected to the water inlet at the upper end of the middle water tank 2, and the water outlet at the bottom of the middle water tank 2 is connected to the low water tank 3. The water inlet at the upper end is connected, and the water outlet at the bottom of the lower water tank is connected to the water inlet of the electromagnetic heating unit 5 through a pipeline. , electromagnetic coil 5-3, electromagnetic heating tube control valve 5-1 and electromagnetic coil control switch 5-4, the water outlet end of the electromagnetic heating unit 5 is connected to the water inlet end of the circulation pipe network 6, and there a...

Embodiment 2

[0033] Take the quartz tube heating unit as an example to describe the technical scheme of the present invention in detail below

[0034] like Figure 4As shown: the heating unit is a quartz tube heating unit 12, which is also composed of multiple parallel quartz tube heating tubes. Each quartz tube heating includes a hollow water delivery pipe and quartz tubes distributed outside the water delivery pipe. Each quartz tube The heating tubes are provided with valves and quartz tube control switches. The entire quartz tube heating unit 12 is provided with a casing 13 outside, and the casing 13 is connected to the high-level water tank 1 through a hot air delivery pipe 14 . Others are the same as embodiment 1.

[0035] In this embodiment, with respect to embodiment 1, when the quartz tube heating unit 12 works, a large amount of hot air can be produced, and these hot air are sent into the high-level water tank 1 through the hot air delivery pipe 14 to preheat the circulating wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com