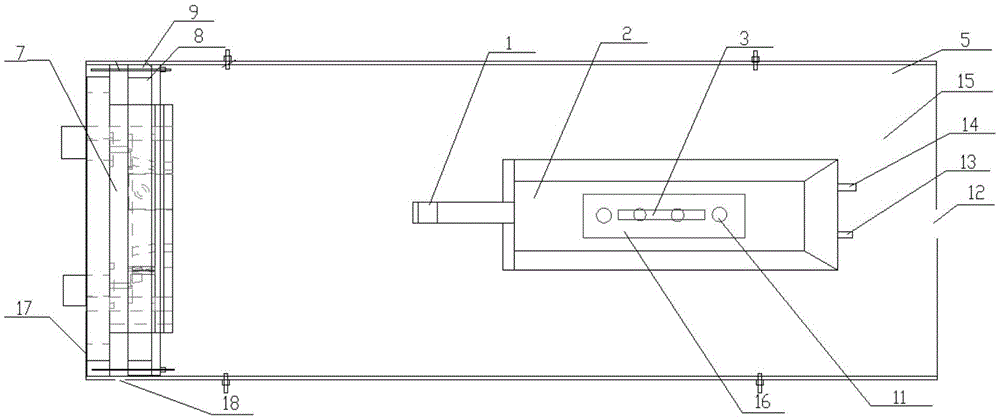

Closed microscopic shooting system

A technology of a shooting system and a base plate, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve problems such as the contradiction between magnification and shooting field of view, and achieve lower instrument costs, improved speed and clarity, and reduced manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

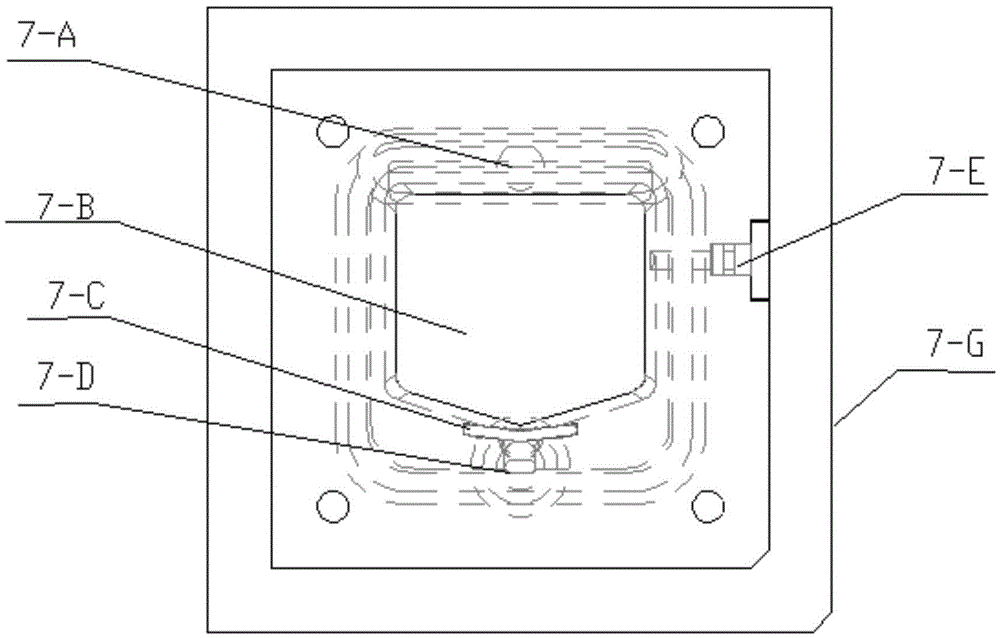

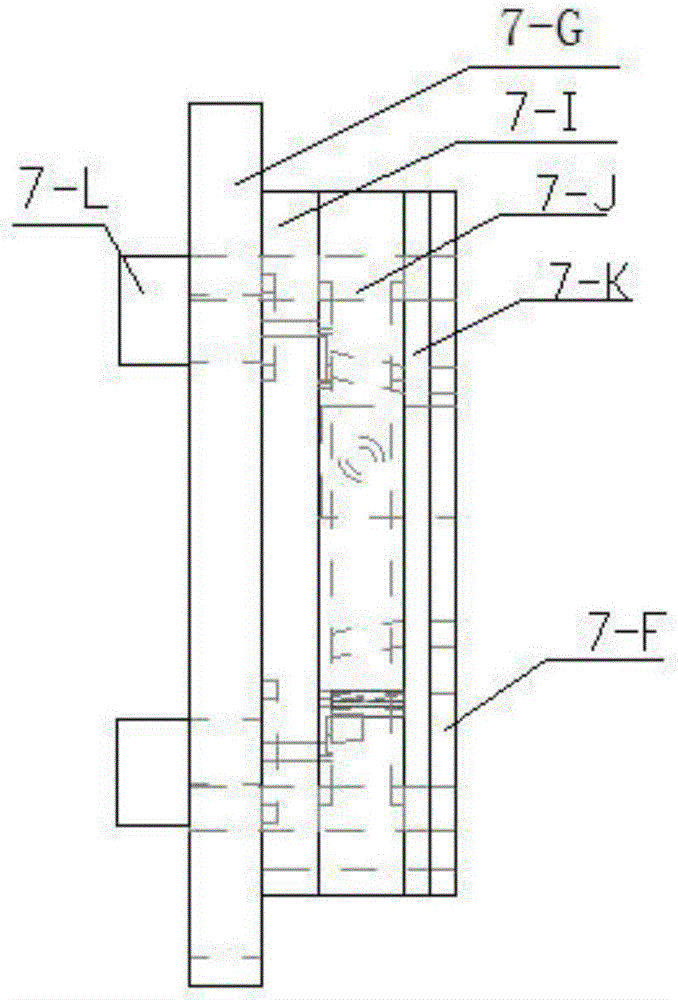

[0025] Optical lens 1, the specification is CCTVLENS, focal length 16mm, CCD camera 2, adopts Sony 700TVCCD model, the two are connected to form the core component of the microscopic shooting system, and are used to shoot the behavior changes of water fleas; the CCD camera is fixed on the sliding block 16 through M5 screws Above, the sliding block 16 is made of aluminum alloy, fixed in the sliding groove 3 by M4 screws, the sliding groove 3 is located on the bottom plate 15, the sliding block 16 can adjust the horizontal distance between the optical lens 1 and the reaction chamber 7 through the sliding groove 3, and the adjustment range 0-30mm. There are two nuts on the fixing screw M4, the bottom end of the screw M4 is fixed in the sliding groove 3 through these two nuts, the top of the screw M4 fixes the sliding block 16, and the position of the top of the screw is adjusted by changing the positions of the two nuts. Protruding distance, thereby adjusting the distance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com