Aeroengine electrical accessory conductivity measurement loop connection method

An aero-engine and measurement loop technology, which is applied in the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of increasing the workload of the designer's circuit layout, wasting limited channel resources, and wasting longitudinal channels, etc. The effect of increasing volume, increasing utilization, eliminating workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

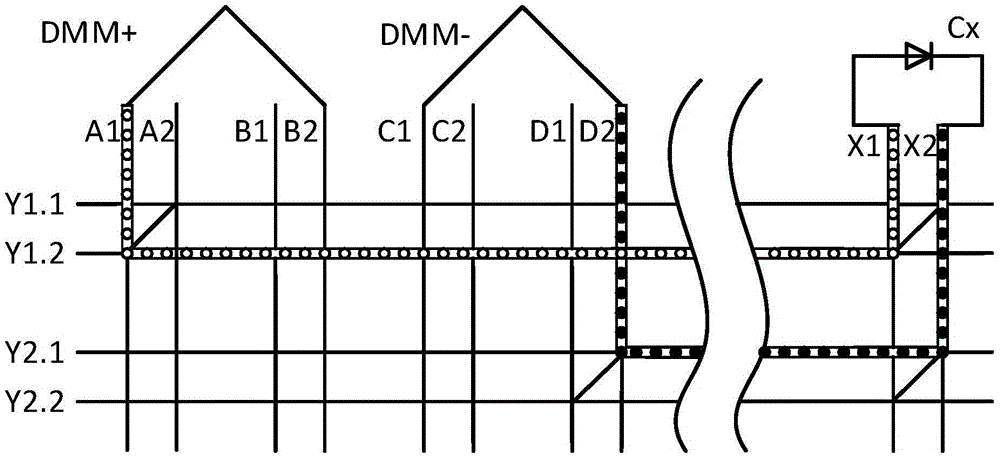

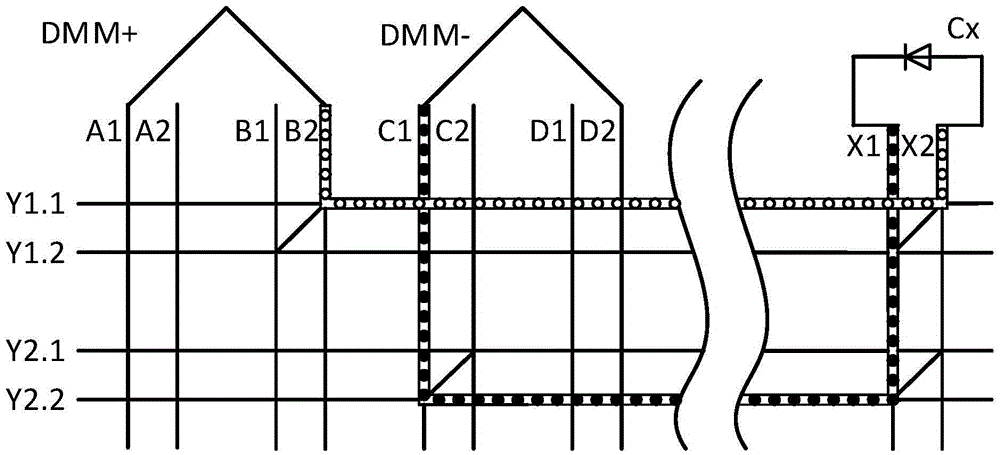

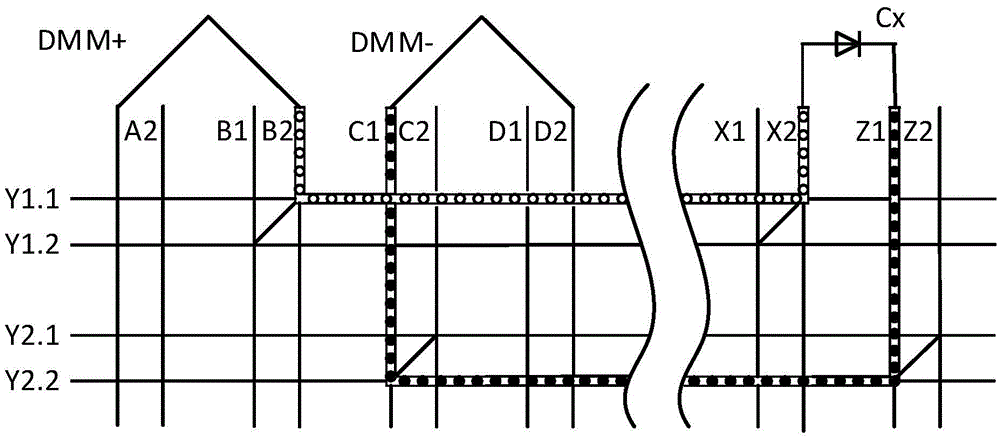

[0022] The method for connecting the electrical accessory continuity measurement circuit of the aeroengine according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The method for connecting the continuity measurement circuit of the aeroengine electrical accessory of the present invention comprises the following sequential steps:

[0024] (1) According to the requirements of the continuity test item of the tested part and the actual wiring situation, assign the longitudinal channel of the double-pole matrix switch to the test equipment and the tested part, and record the distribution; the input of each measurement signal of the test device The positive and negative terminals are respectively connected to two longitudinal channels that do not belong to the same group; the positive and negative terminals of each constant current output of the test equipment are respectively connected to one longitudinal ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com