Expert system based on electrolytic tank real-time production data

A production data and expert system technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as large differences in efficiency and energy consumption, unstable electrolytic cell production, and low level of electrolytic production management and control. The effect of reducing the impact, improving the level of refinement and automation, and improving management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

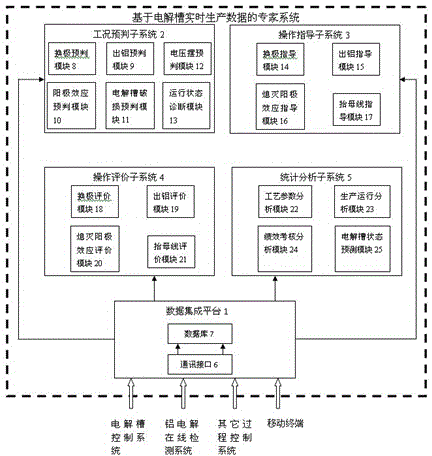

[0024] Such as figure 1 As shown, the expert system based on the real-time production data of the electrolyzer of the present invention includes: a data integration platform 1 , a working condition prediction subsystem 2 , an operation guidance subsystem 3 , an operation evaluation subsystem 4 , and a statistical analysis subsystem 5 .

[0025] The data integration platform 1 is responsible for integrating the real-time data of the production process, providing real-time production data for the working condition prediction subsystem 2, the operation guidance subsystem 3, the operation evaluation subsystem 4, and the statistical analysis subsystem 5; the working condition prediction subsystem 2 is responsible for During the aluminum electrolytic production process, early warnings and alarms are provided for operations and working conditions suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com