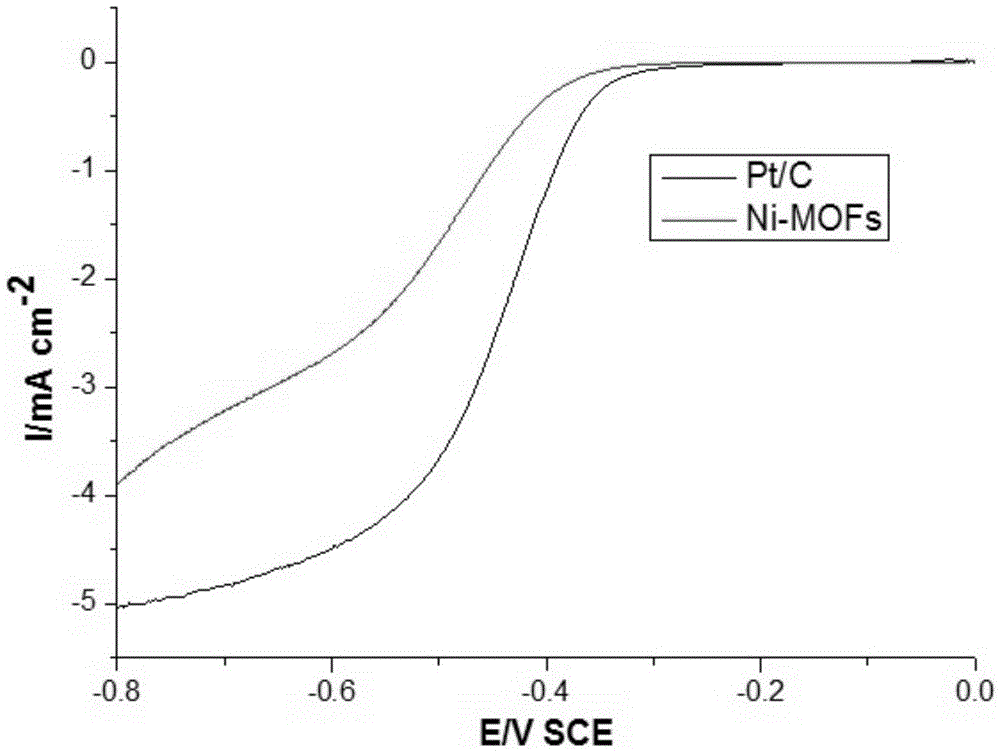

Preparation method of nickel (II)-1,1'-ferrocene dicarboxylic acid complex electrocatalyst

A technology of ferrocene dicarboxylic acid and catalyst, which is applied in the field of chemistry, can solve the problem that electrocatalytic oxygen reduction performance needs to be further improved, and achieves the effects of easy large-scale preparation, low cost of raw materials and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

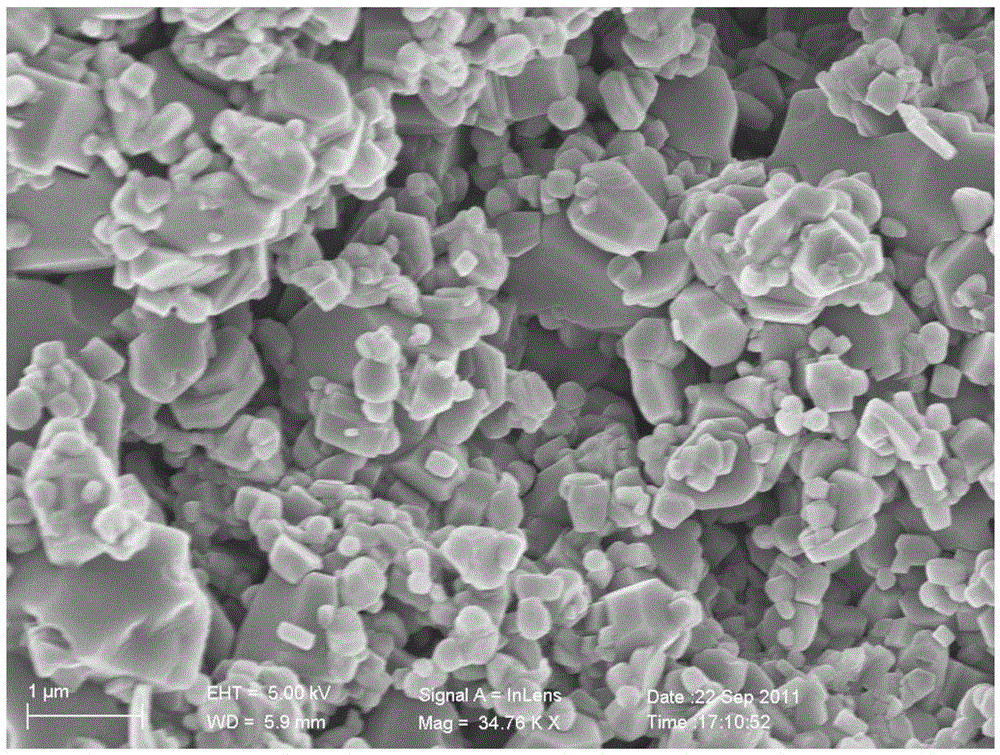

[0022] A kind of preparation method of nickel (II)-1,1'-ferrocene dicarboxylic acid complex electrocatalyst, it may further comprise the steps:

[0023] Step 1: Dissolve nickel acetate and equimolar amounts of 1,1'-ferrocenedicarboxylic acid in 12 mL of DMF, both at a concentration of 0.05 mol / L.

[0024] Step 2: Transfer the solution obtained in step 1 into a Teflon liner with a specification of 25mL, then put it into the kettle shell, and heat the reaction in an oven at a heating temperature of 160°C for a reaction time of 10 hours.

[0025] Step 3: Centrifuge the reaction product of Step 2 at a centrifugal speed of 9000 rpm, wash with water 3 times and ethanol 3 times after centrifugation, and dry in vacuo at 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com